Three-dimensional temperature detector and manufacturing method for same

A technology of temperature detector and manufacturing method, which is applied in the field of semiconductors, can solve the problems of low yield rate, difficult process of suspension beam and suspension structure, etc., and achieve the effect of improving sensitivity, improving device performance and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

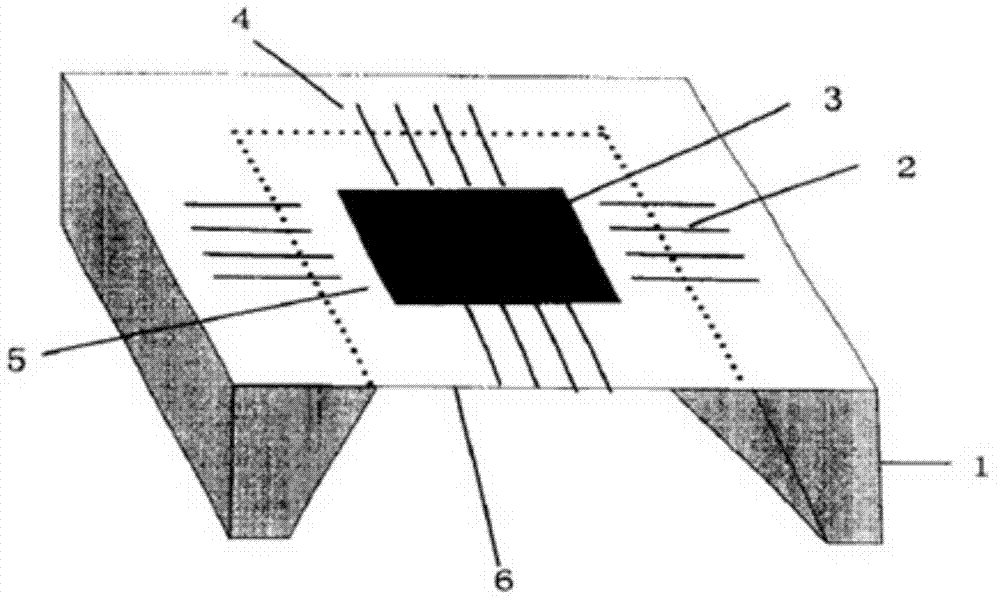

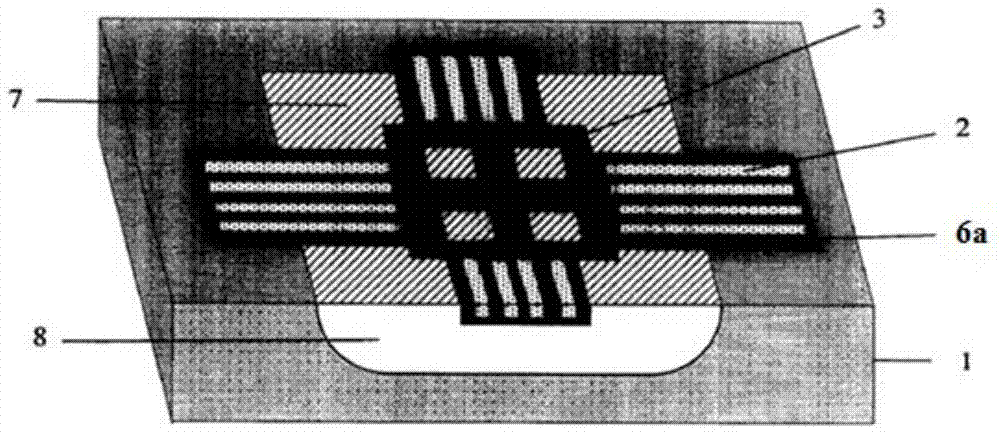

[0052] Embodiment 1 of the present application provides a method for manufacturing a three-dimensional temperature detector. Figure 6 It is a schematic flow chart of the manufacturing method of the three-dimensional temperature detector, and FIG. 7 is a schematic longitudinal sectional view of the device structure corresponding to each step of the manufacturing method of the three-dimensional temperature detector. Below, combine Figure 6 7, the manufacturing method of the three-dimensional temperature detector of this embodiment is described.

[0053] Step S601: depositing a first dielectric layer 10 on the substrate 9, such as Figure 7A shown.

[0054] In this embodiment, the substrate may be a wafer commonly used in the semiconductor manufacturing field, such as a silicon wafer, a silicon-on-insulator (Silicon-On-Insulator, SOI) wafer, a silicon-germanium wafer, a germanium wafer, or A gallium nitride (Gallium Nitride, GaN) wafer or the like, which is not limited in th...

Embodiment 2

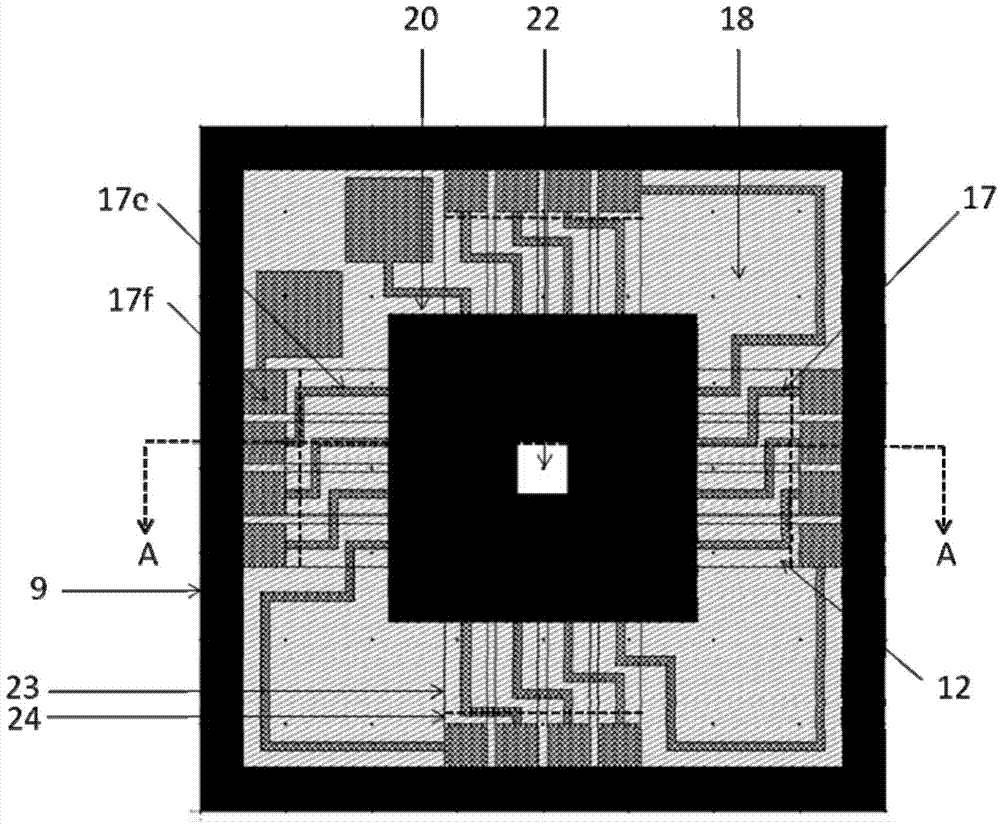

[0118] Embodiment 2 of the present application provides a three-dimensional temperature detector. image 3 is a schematic diagram of the top view structure of the three-dimensional temperature detector, Figure 4 is along image 3 The schematic diagram of the longitudinal section structure in the direction of A-A, Figure 5 It is a schematic diagram of the side view structure of the three-dimensional temperature detector. Such as Figure 3-5 As shown, the three-dimensional temperature detector includes:

[0119] Substrate (9);

[0120] A first dielectric layer 10 located on the surface of the substrate (9);

[0121] Located on the surface of the first dielectric layer 10, the first thermopile material structure 12, the second dielectric layer structure 14, the second thermopile material structure 17, and the third dielectric layer structure 18 are stacked sequentially from bottom to top , and, the first dielectric layer 10, the second dielectric layer structure 14, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com