Spray gun, spray coating device, and spray coating method

A technology of spray guns and nozzles, which is applied in the direction of spraying devices, liquid spraying devices, and devices for coating liquid on surfaces, etc. It can solve the problems of reduced spraying amount, complex flow path structure, and resin adhesion, so as to improve physical properties and suppress pores. Effect of occurrence and inhibition of resin adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4)

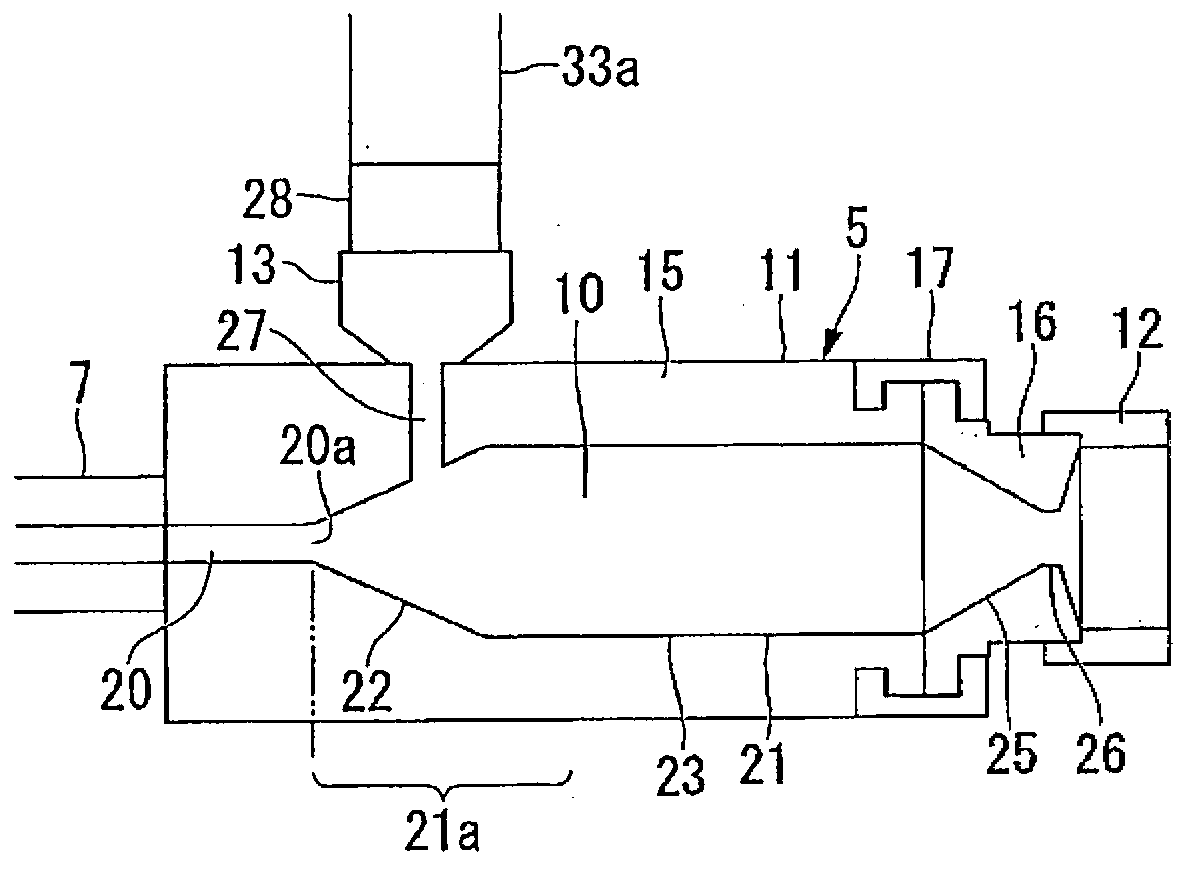

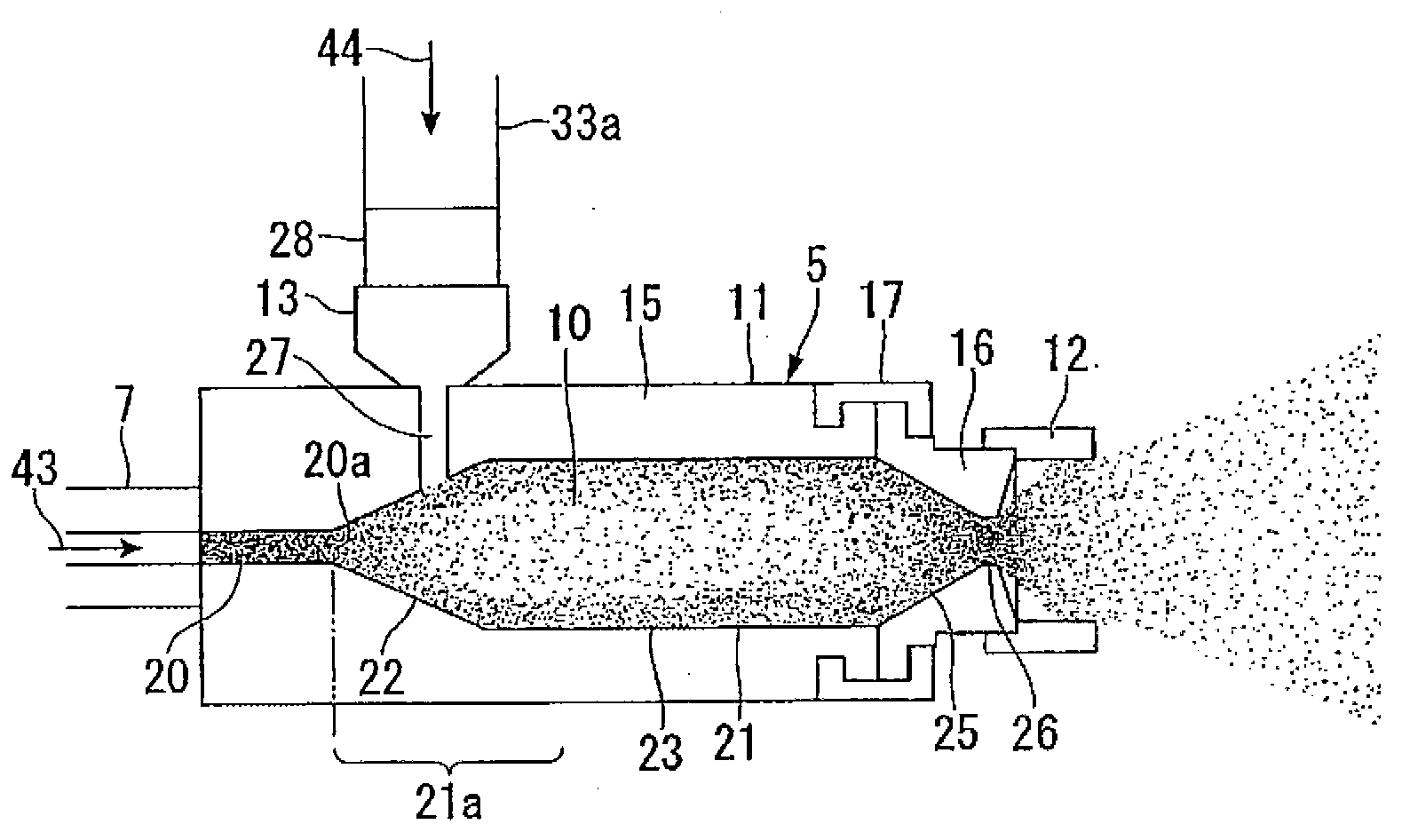

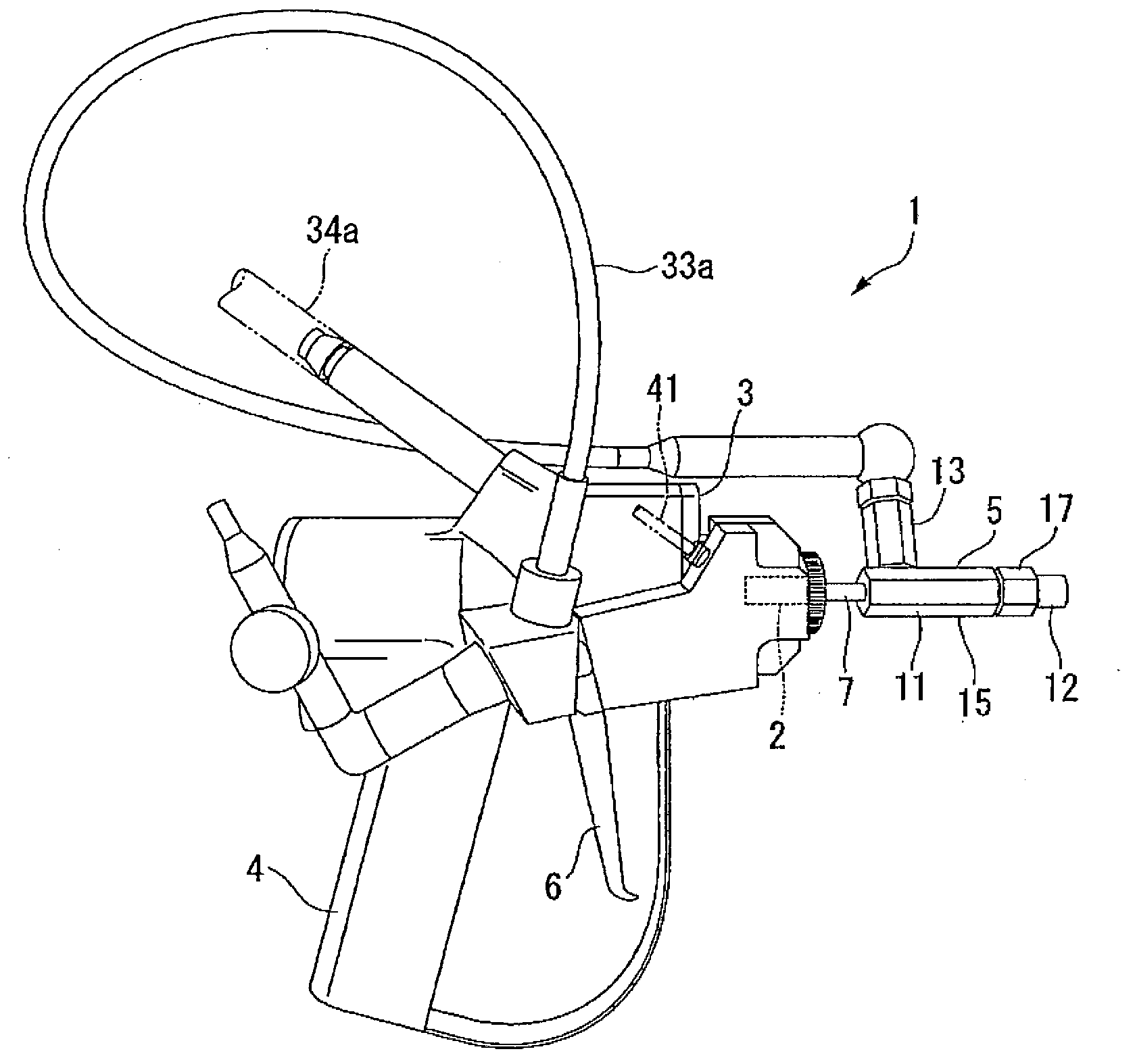

[0144] Use with Figure 1 ~ Figure 4 The spray application device 30 of the shown spray gun 1 forms a resin layer made of polyurethane on a base layer made of a plastic plate.

[0145] A main agent containing an isocyanate-based terminal prepolymer composed of MDI and polyether polyol is used as the first liquid agent 41, and a polyol containing DETDA (diethyltoluenediamine) is used as the second liquid agent 42 Department of curing agent.

[0146] Air is used as gas 44 .

[0147] Table 1 shows the results of measuring the physical properties of the resin layer. The measuring method of each physical property shall comply with JISA6021.

[0148] The following method was used for the evaluation of the thermal insulation performance.

[0149] Using the resin sheet produced by the spraying construction device 30 equipped with the spray gun 1, the opening of the box made of expanded styrene was blocked, and the resin sheet was irradiated with infrared rays using an infrared lam...

Embodiment 5)

[0151] As the gas 44 , carbon dioxide (CO 2 ) was used instead of air to form a resin layer. Other test conditions are based on Examples 1-4.

[0152] Table 1 shows the results of measuring the physical properties of the resin layer.

Embodiment 6、7)

[0164] Use with Figure 1 ~ Figure 4 The spray application device 30 of the shown spray gun 1 forms a resin layer made of polyurea.

[0165] A main agent containing an isocyanate component is used as the first liquid agent 41 , and a curing agent containing an amine compound is used as the second liquid agent 42 .

[0166] Air is used as gas 44 . Other test conditions are based on Examples 1-4.

[0167] Table 2 shows the results of measuring the physical properties of the resin layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com