Automatic tin adding electric soldering iron

An electric soldering iron and automatic technology, applied in the field of electronics, can solve the problems of liquid tin having no fluidity, poor practicability, and difficult to spray components, etc., and achieve the effects of simple and convenient use, simple internal structure, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be illustrated with examples in conjunction with the drawings.

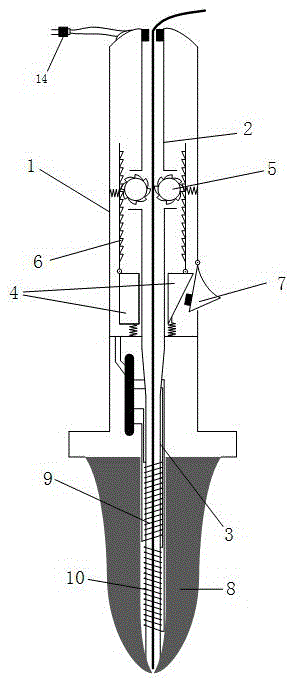

[0023] The invention is composed of a transmission module and a heating module.

[0024] The transmission module includes a housing 1, an inner cavity 2, a pushing body 4, a round gear 5, a spur gear 6, a ceramic inner cavity 3 and a wire button 7.

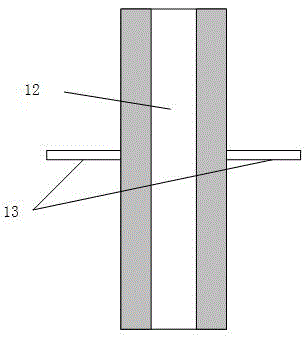

[0025] The inner cavity 2 is made of ordinary plastic, connected to the entire soldering iron, and is a channel for the transmission of tin wires of different specifications. The shape is a hollow cylinder with a diameter of 6mm. Butt with the ceramic inner cavity 3 at the lower end to form an internal channel.

[0026] The shell 1 is made of heat-insulating plastic and has a hollow cylindrical shape with a diameter of 17mm. A protrusion is provided at the lower end of the shell 1 to prevent the heating element 8 from being touched by hand sliding, and the diameter of the protrusion is 28mm.

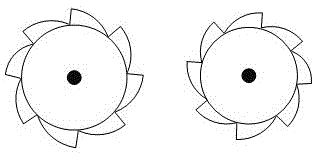

[0027] The circular gear 5 is locate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com