Hollow sound attenuation spiral pipe extrusion mold

A technology of sound-absorbing spiral pipe and extrusion die, which is applied in the field of plastic machinery, can solve the problems that the pipe can not achieve the effect of sound-absorbing, the water flow cannot flow against the pipe wall, and the noise pollution of the surrounding environment, so as to achieve convenient and reliable installation and save materials. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

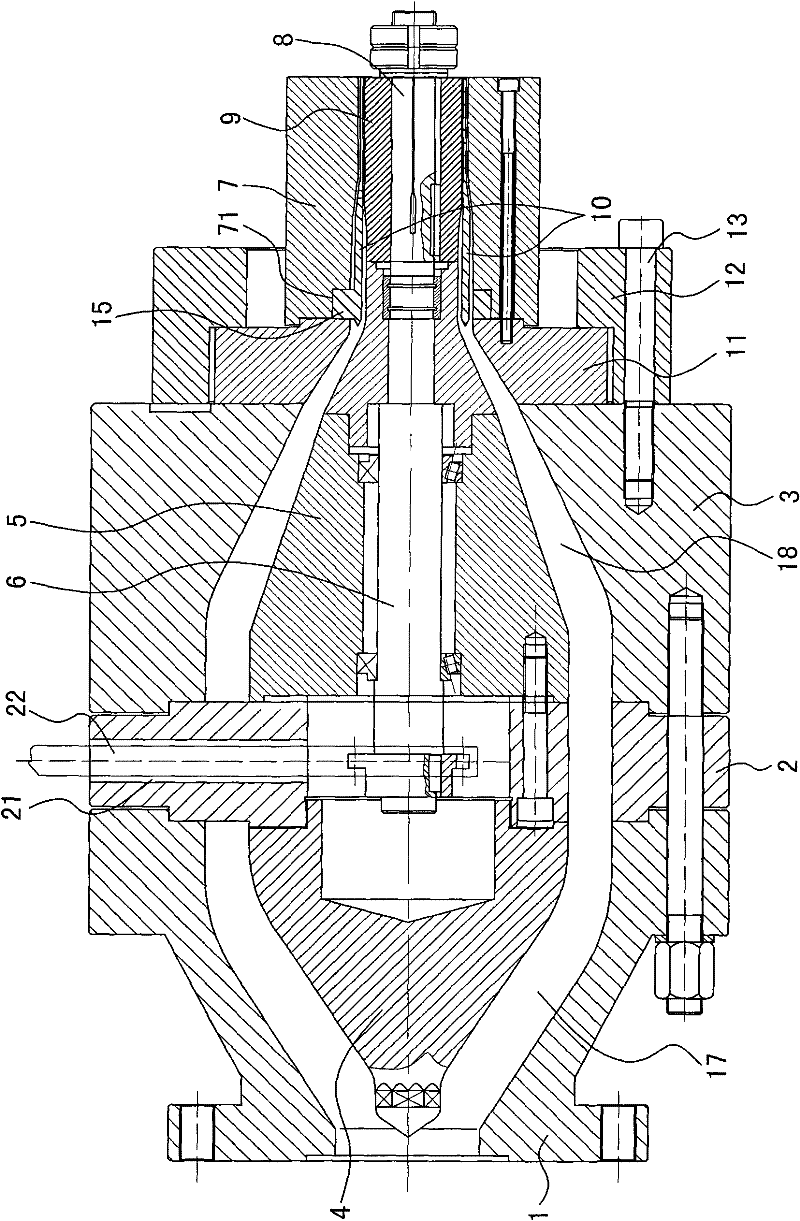

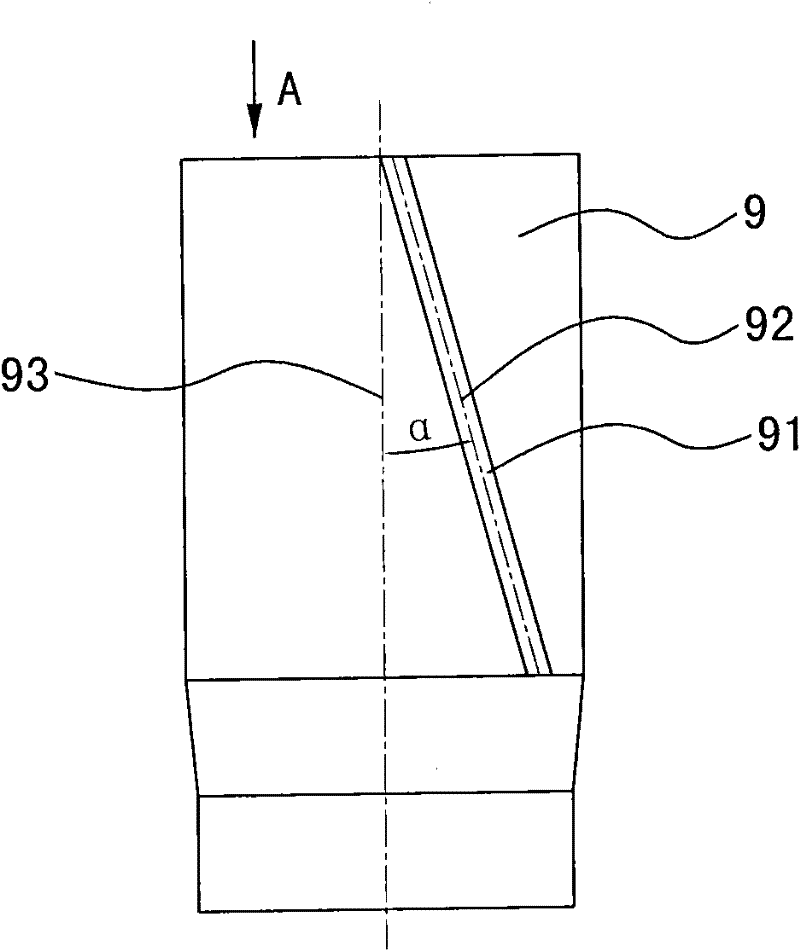

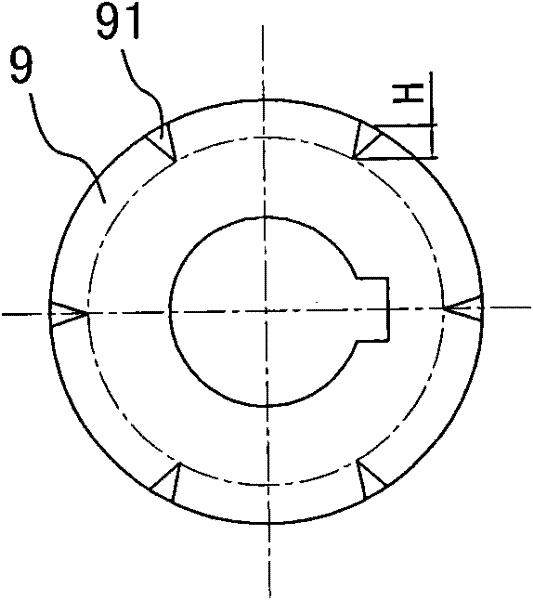

[0010] The invention relates to an extrusion die of a hollow sound-absorbing spiral pipe, such as Figure 1-Figure 3 As shown, it includes a connection seat 1 installed on the head of the extruder, the connection seat 1 is connected to the head body 3, the outer wall of the head body 3 is installed with a die 7, and a mandrel 8 and a hollow core strip 10 are installed in the die 7 , the connecting seat 1 and the head body 3 are provided with a shunt cone 4, the shunt cone 4 is connected to the current collecting cone 5 through the shunt plate 2, and a shunt cavity 17 is formed between the shunt cone 4 and the connecting seat 1, and the current collecting cone 5 A collecting cavity 18 is formed between the head body 3, which is characterized in that a rotating shaft 6 is installed in the collecting cone 5, the rotating shaft is driven by power, the rotating shaft is connected to the mandrel 8, and a spiral core is installed on the outer wall of the mandrel 8 Stick 9. In this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com