Cold-producing medium loop

A refrigerant circuit, refrigerant technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as poor space efficiency, and achieve the effect of preventing pressure rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

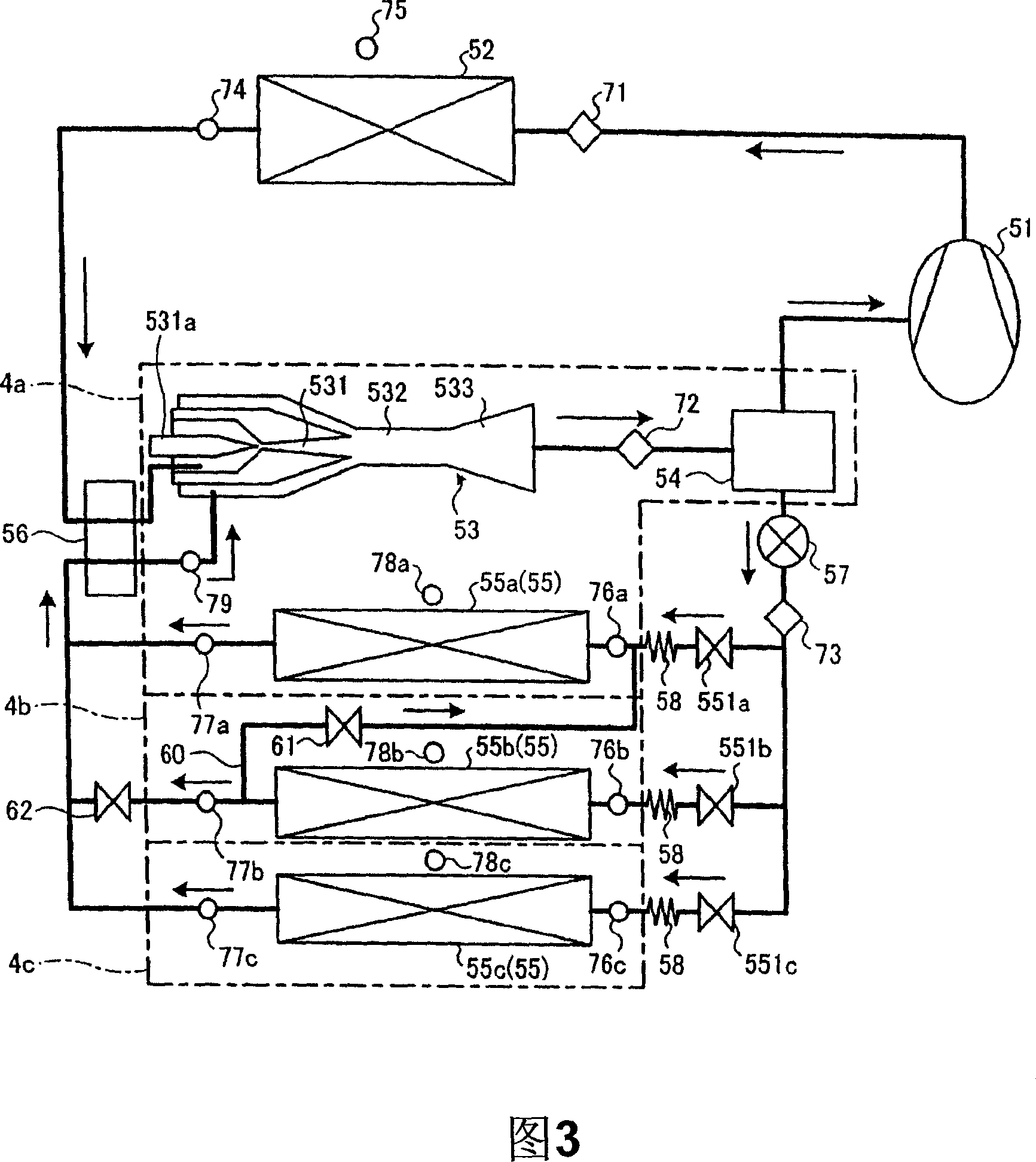

[0106] Next, preferred embodiments of the refrigerant circuit of the present invention will be described in detail with reference to the drawings. However, the present invention is not limited by these embodiments.

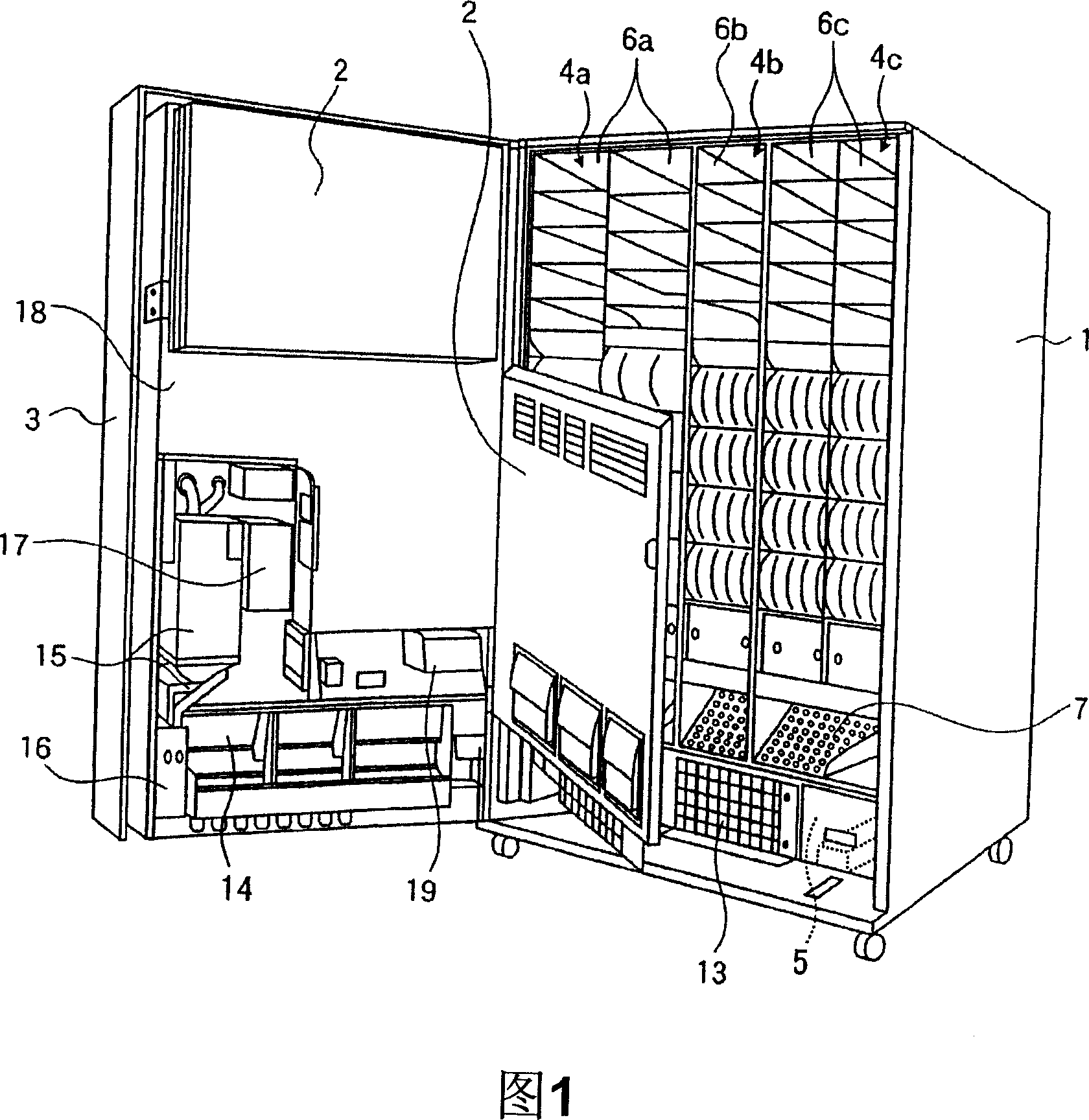

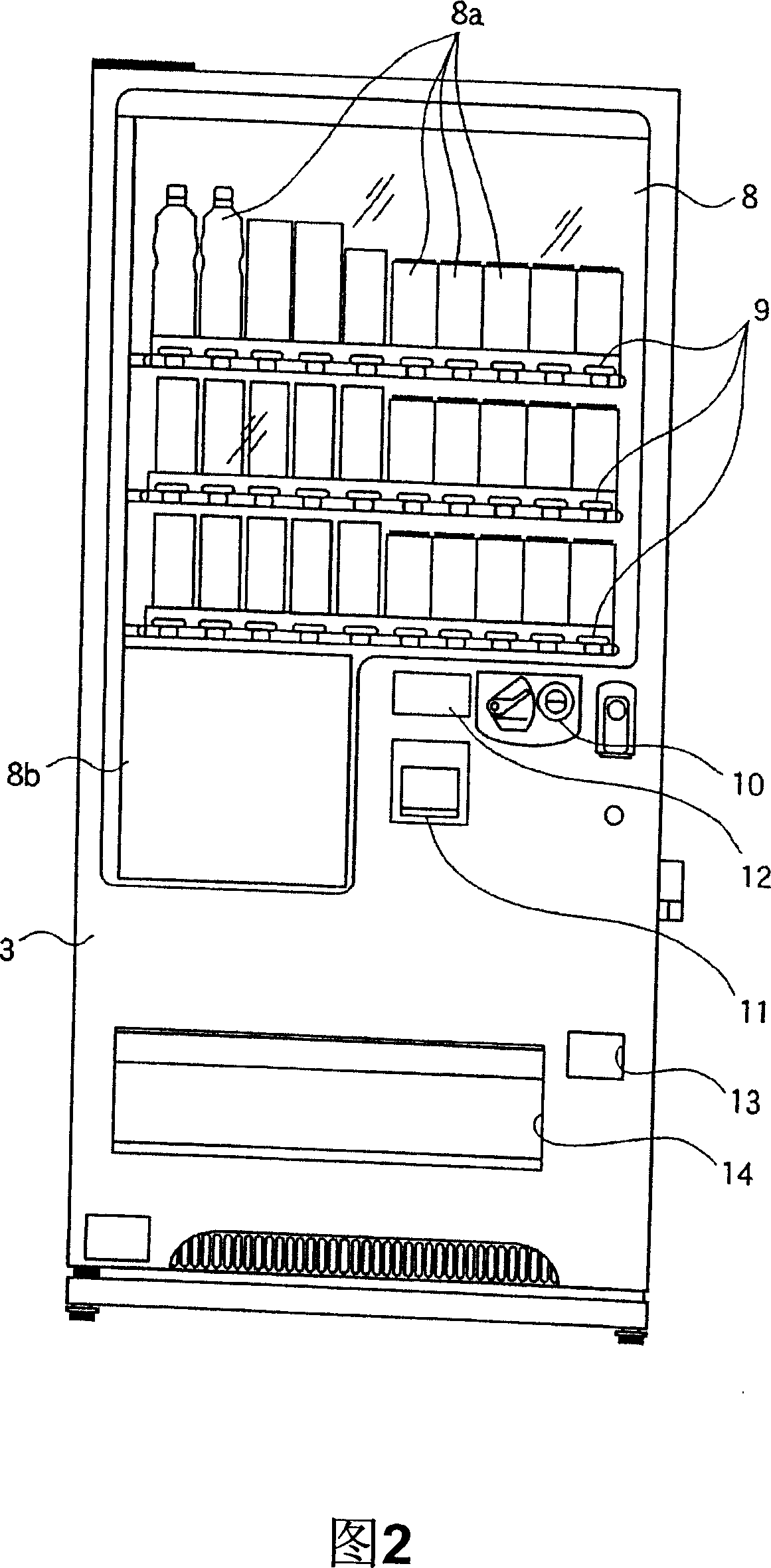

[0107] First, a vending machine suitable for use with the refrigerant circuit of the present invention will be described. Fig. 1 is a perspective view showing an open interior state of an automatic vending machine to which the refrigerant circuit of the present invention is suitable. Fig. 2 is a front view of the vending machine shown in Fig. 1 .

[0108] The automatic vending machine shown here is used to sell commodities such as canned beverages or PET bottled beverages, and includes a main body box 1, an inner door 2 and a main door 3 as shown in FIG. 1 .

[0109] As for the main body box 1, it is constructed firmly by proper combination of a plurality of steel plates, and the front becomes an open rectangle. Inside the main body box, three commodity storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com