LED backlight integration and encapsulation structure and encapsulation method

An LED backlight board and integrated packaging technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of high price, affecting the life of LEDs, and large LED light decay, so as to reduce packaging costs, save electrode materials, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

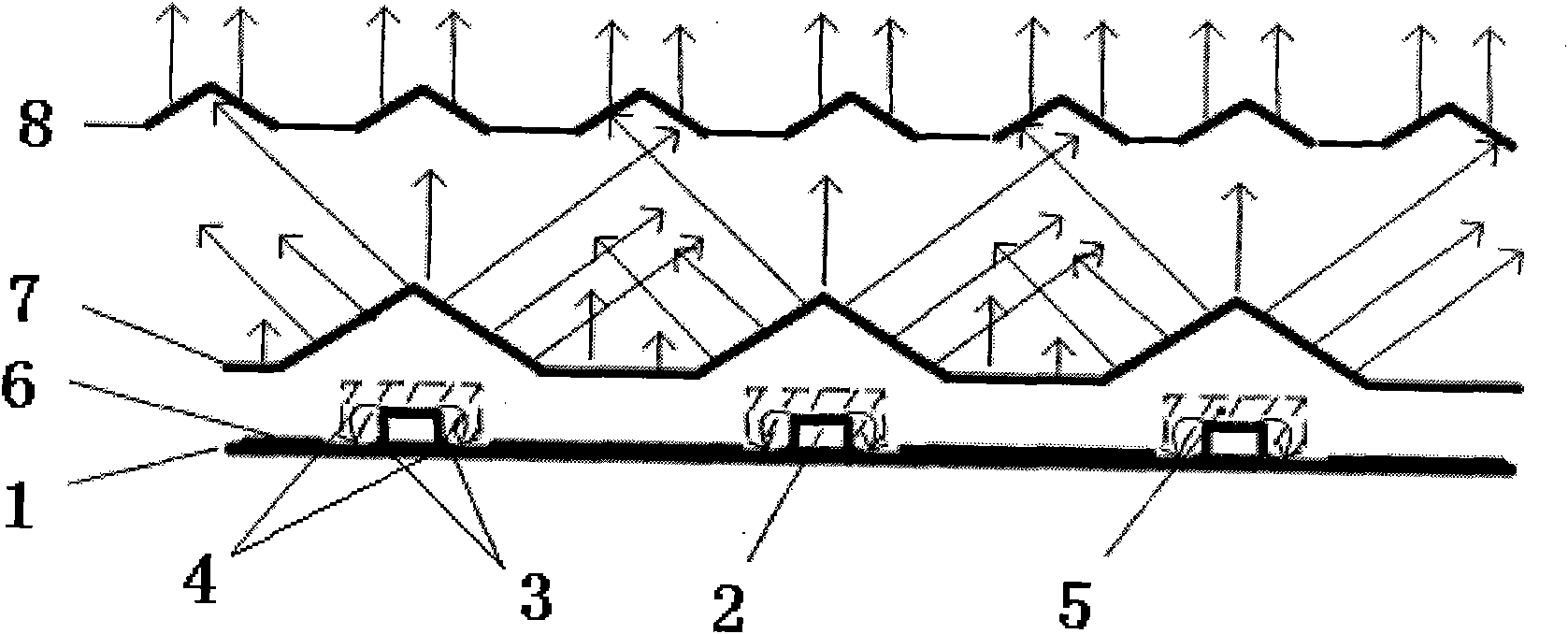

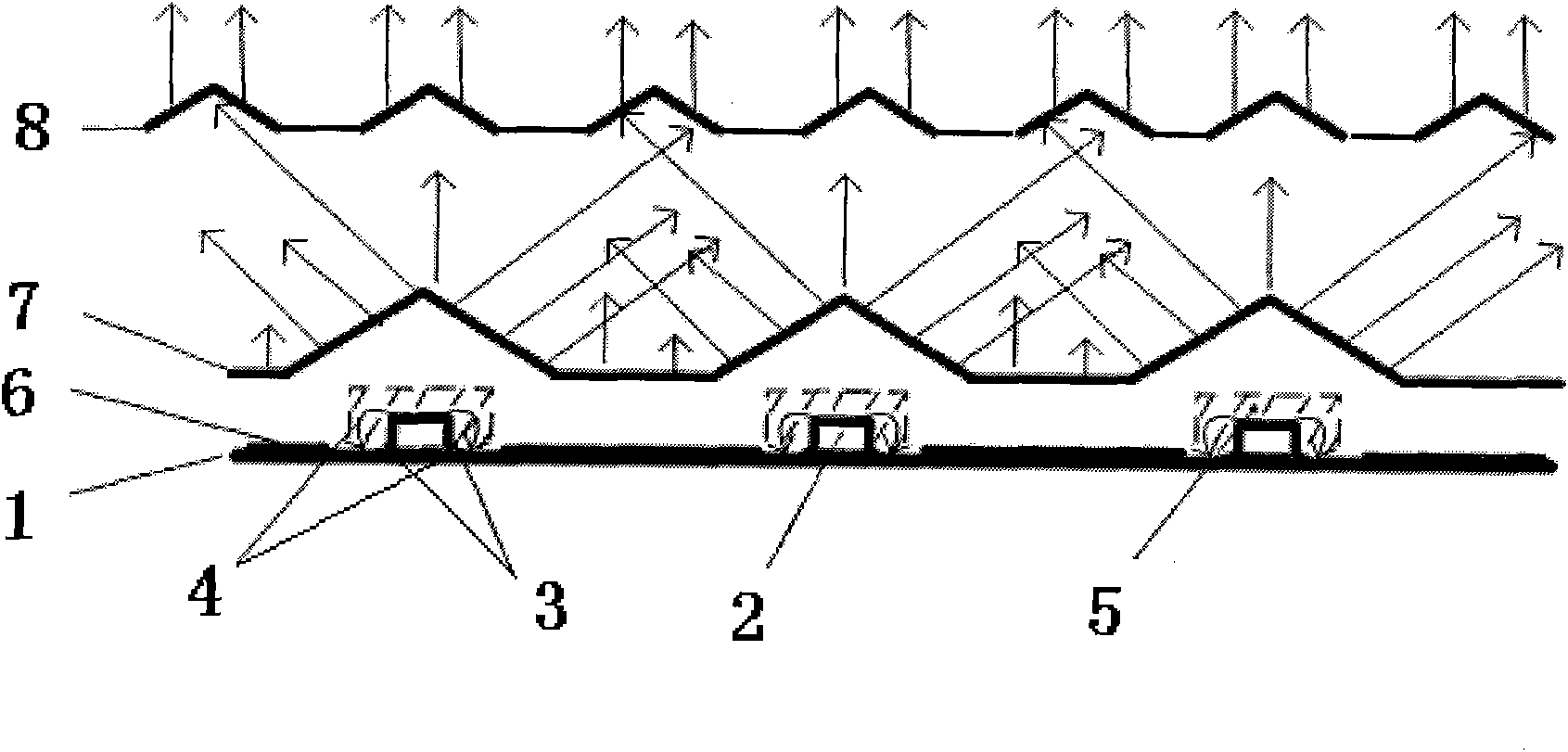

[0028] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] See attached figure 1 As shown, the LED backlight integrated packaging structure includes a substrate 1 and a reflective layer 6 provided on the substrate 1, and a light guide diffusion plate 7 and a prism are sequentially arranged above the substrate 1 provided with the reflective layer 6 from bottom to top. Board 8, wherein: LED blue light dies 2 are distributed in an array on the substrate 1, and the LED blue light dies 2 are distributed in a square, square, triangular, quadrilateral, hexagonal or five-pointed star geometric array; The periphery of the LED blue light tube core 2 is coated with a yellow light phosphor and an epoxy resin layer 5; the light guide diffusion plate 7 is a light-transmitting material with a high refractive index, and the light-transmitting material with a high refractive in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com