Radio frequency cable with integrated polytetrafluoroethylene insulating surface silver-plating outer conductor, and machining method for radio frequency cable

A polytetrafluoroethylene, insulating surface technology, used in waveguides, circuits, electrical components, etc., can solve problems such as inappropriate high-frequency transmission, achieve high flexibility, improve electrical conductivity and firmness, and ensure the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

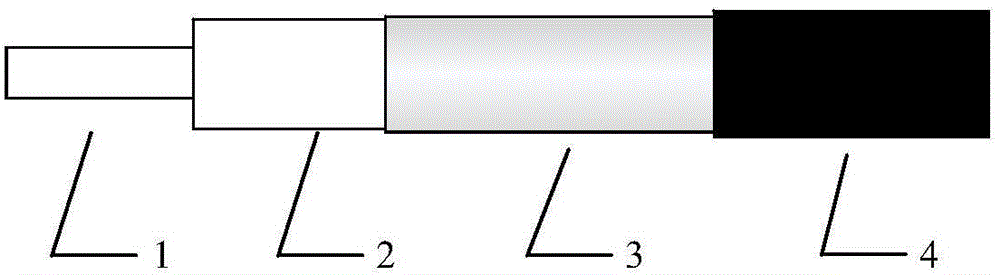

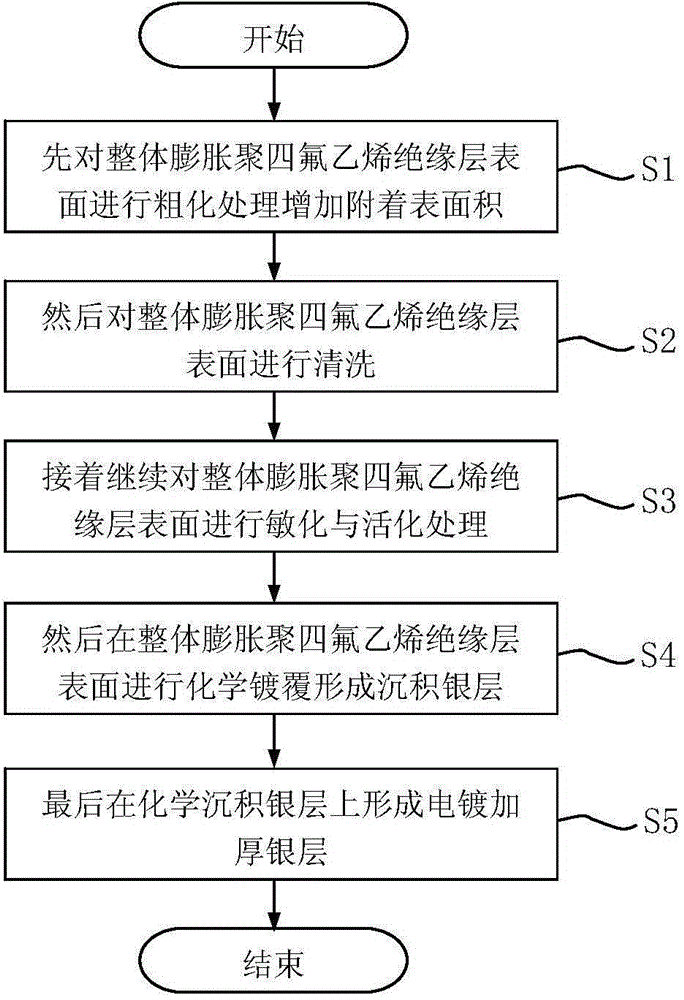

[0017] figure 1 It is a structural schematic diagram of a radio frequency cable with an integrally expanded polytetrafluoroethylene insulating surface and an integrally silver-plated outer conductor of the present invention.

[0018] See figure 1 , the radio frequency cable with integrally expanded polytetrafluoroethylene insulation provided by the present invention includes an inner conductor 1, an insulating layer 2, an outer conductor 3 and an outer sheath 4 in sequence from the inside to the outside, wherein the inner conductor 1 is silver-plated copper single line; the insulating layer 2 is an integrally expanded polytetrafluoroethylene insulating layer; the outer conductor 3 includes a chemically deposited silver layer and an electroplating thickened silver layer attached to the integrally expanded polytetrafluoroethylene insulating layer; the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com