A mipm type internal field emission cathode

A field emission cathode and bottom electrode technology, applied in the field of vacuum electronics and materials science, can solve the problems of low emission efficiency and low emission current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

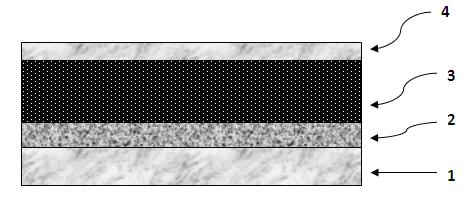

[0013] refer to figure 1 , the material of the bottom electrode 1 is gold with a thickness of 500 nm; the material of the insulating layer 2 is SiO 2 , with a thickness of 100 nm; the material of the electron storage and transport layer 3 is porous silicon with a thickness of 40 μm, its average conductivity is 0.01 Ω, the average porosity is 50%, and the average pore diameter is 30 nm; the material of the top electrode 4 is gold , with a thickness of 15 nm. at 10 -5 Under torr pressure, the measured emission efficiency is 1.5%, and the beam decays by 1% after 20 hours of continuous operation.

Embodiment 2

[0015] refer to figure 1 , the material 1 of the bottom electrode is chromium with a thickness of 200 nm; the material of the insulating layer 2 is HfO 2 , with a thickness of 300 nm; the material of the electron storage and transport layer 3 is porous silicon, with a thickness of 40 μm, an average conductivity of 0.01 Ω, an average porosity of 50%, and an average pore diameter of 50 nm; the material of the top electrode 4 is Ag , with a thickness of 10 nm. at 10 -5 Under torr pressure, the measured emission efficiency is 1.5%, and the beam decays by 1% after 20 hours of continuous operation.

Embodiment 3

[0017] refer to figure 1 , the material of the bottom electrode 1 is Ag, and the thickness is 200 nm; the material of the insulating layer 2 is Ta 2 o 5 , with a thickness of 400 nm; the material of the electron storage and transport layer 3 is porous silicon, with a thickness of 30 μm, an average conductivity of 0.01 Ω, an average porosity of 50%, and an average pore diameter of 30 nm; the material of the top electrode 4 is ZrN , with a thickness of 8 nm. at 10 -5 Under torr pressure, the measured emission efficiency is 1.3%, and the beam decays by 1% after 20 hours of continuous operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com