Control device and method for steam turbine regulating valve

A technology of steam turbines and regulating valves, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems that are huge, affect the normal operation of power stations, and are impractical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

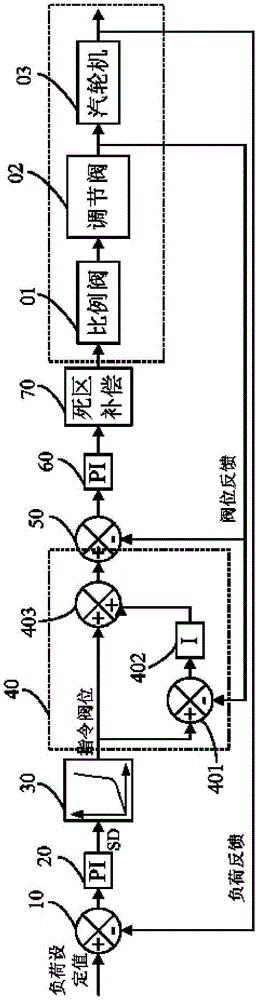

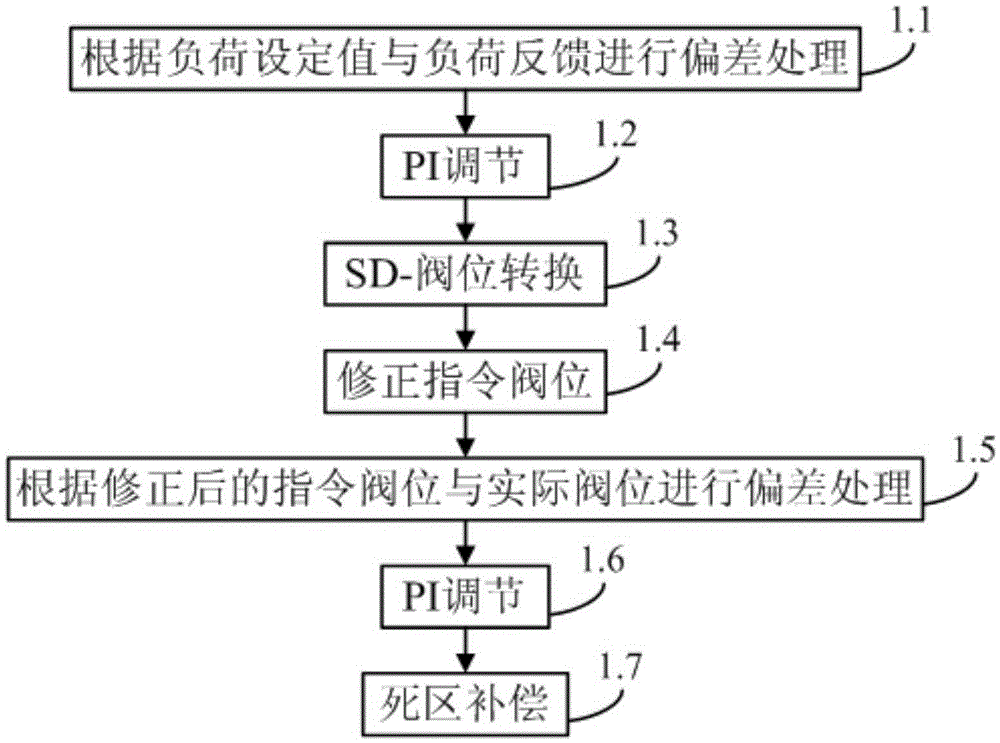

Method used

Image

Examples

Embodiment 1

[0076] In this embodiment, the steam turbine control valve control device and method are mainly used to control the high pressure valve.

[0077] The following is a brief introduction to the control principle of the oil motor:

[0078] The oil motor mainly includes a proportional valve, a solenoid valve, a quick unloading valve (CVP) controlled by the solenoid valve, and a servo piston. The structure of the oil motor belongs to the prior art, and the embodiment of the present application does not describe it in depth.

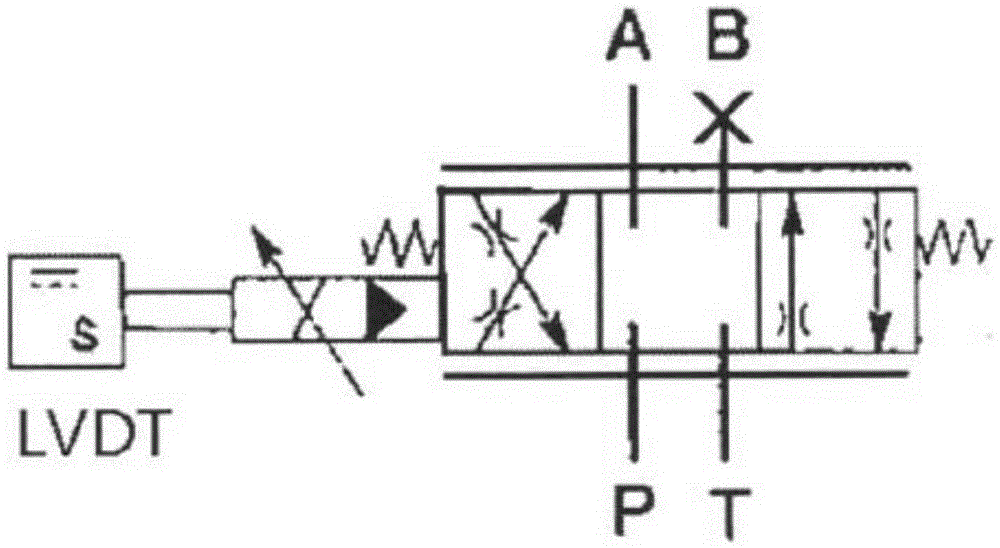

[0079] Please refer to image 3 , is the functional schematic diagram of the proportional valve.

[0080] The proportional valve has four oil ports, P is the power oil port, A and B are the working oil ports, and T is the oil return port. Among them, the working oil port only uses the A port, and the A port can communicate with the oil engine oil cavity, and the B port is blocked. The position of the proportional valve spool is monitored by the LVDT (Linear...

Embodiment 2

[0115] In this embodiment, the steam turbine control valve control device and method are mainly used to control the medium pressure valve.

[0116] Through the research on the oil pressure shock of high and medium pressure valves, it is found that the reasons for the oil pressure shock of high and medium pressure valves are slightly different.

[0117] The fundamental reason for the oil pressure shock of the high-pressure valve is that the dead zone compensation setting of the control card is unreasonable, and the dead zone setting needs to be adapted to the slope of the SD-command valve position curve. The deadband needs to be extended at high slopes.

[0118] Please refer to Figure 12 , is the overpressure record of the diesel engine during the relevant medium pressure valve test. At the beginning of the test, the command valve position drops from 100% to 50% as a fast closing process, and then slow closing. At this time, the oil motor produces an oil pressure shock, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com