Electromechanical ventilating valve capable of controlling gas pressure inside closed cavity

A technology of gas pressure and closed cavity, which is applied to aircraft parts, aircraft power units, power unit fuel supply, etc., can solve the problems of limited adjustment, increase the structural weight of fuel tanks, etc., to increase the service life and reduce the structural weight , the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

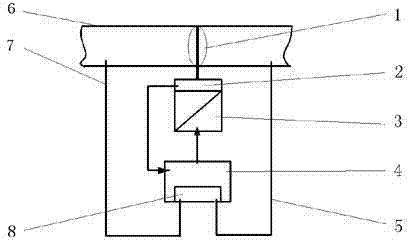

[0012] figure 1 It is a schematic diagram of an embodiment of an electromechanical ventilation valve for controlling gas pressure in a closed cavity of the present invention. The closed cavity of this embodiment is an aircraft fuel tank. An electromechanical ventilation valve for controlling gas pressure in a closed cavity in this embodiment includes an electric actuator 3 with a rotating shaft; The valve 1 that is cut off; the controller 4 that controls the rotation of the rotating shaft of the electric actuator 3; the pressure difference sensor 8 that transmits the collected fuel tank gas pressure and the external atmospheric pressure to the pressure difference sensor 8 of the controller 4 ; The controller 4 is preset with the upper limit and the lower limit of the aircraft fuel tank gas pressure limit range compared with the pressure difference between the incoming fuel tank gas pressure and the external atmospheric pressure.

[0013] Further, the electromechanical ventil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com