VOC automatic processing system used for spray painting operation and optimized adjustment method of VOC processing

An automatic processing and adjustment method technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve problems such as exhaust gas temperature fluctuations, divergence, and system processing efficiency effects, and achieve fast accuracy, fast control, and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

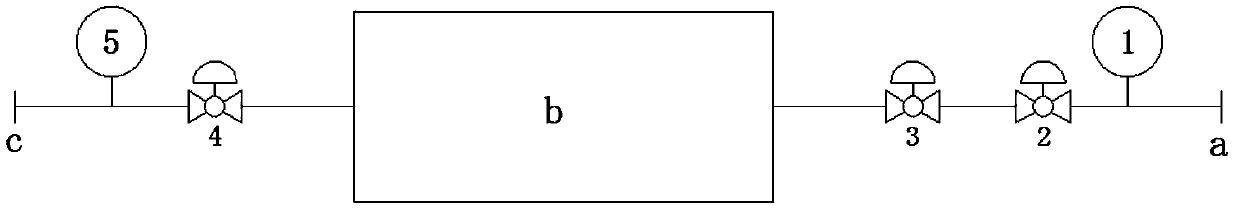

[0022] The VOCs automatic processing system used for painting operations according to the present invention automatically measures and records the VOCs concentration values in the painting operation area and the front-end and rear-end exhaust gases of the pipelines of the VOCs automatic processing system in real time, and processes and calculates the measured VOCs concentration value data , and by controlling the on-off of the valve in the VOCs automatic treatment system, the control of the exhaust gas treatment cycle is realized.

[0023] When the concentration of VOCs in the exhaust gas in the painting operation area or the VOCs automatic treatment system changes, the VOCs automatic treatment system automatically adjusts and controls the valve to ensure the reliabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com