Laptop batter assembling machine

A notebook computer and installation machine technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems affecting the use of notebook computers, cumbersome manual operation steps, and inaccurate installation positions, so as to achieve stable transportation and reduce production costs , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

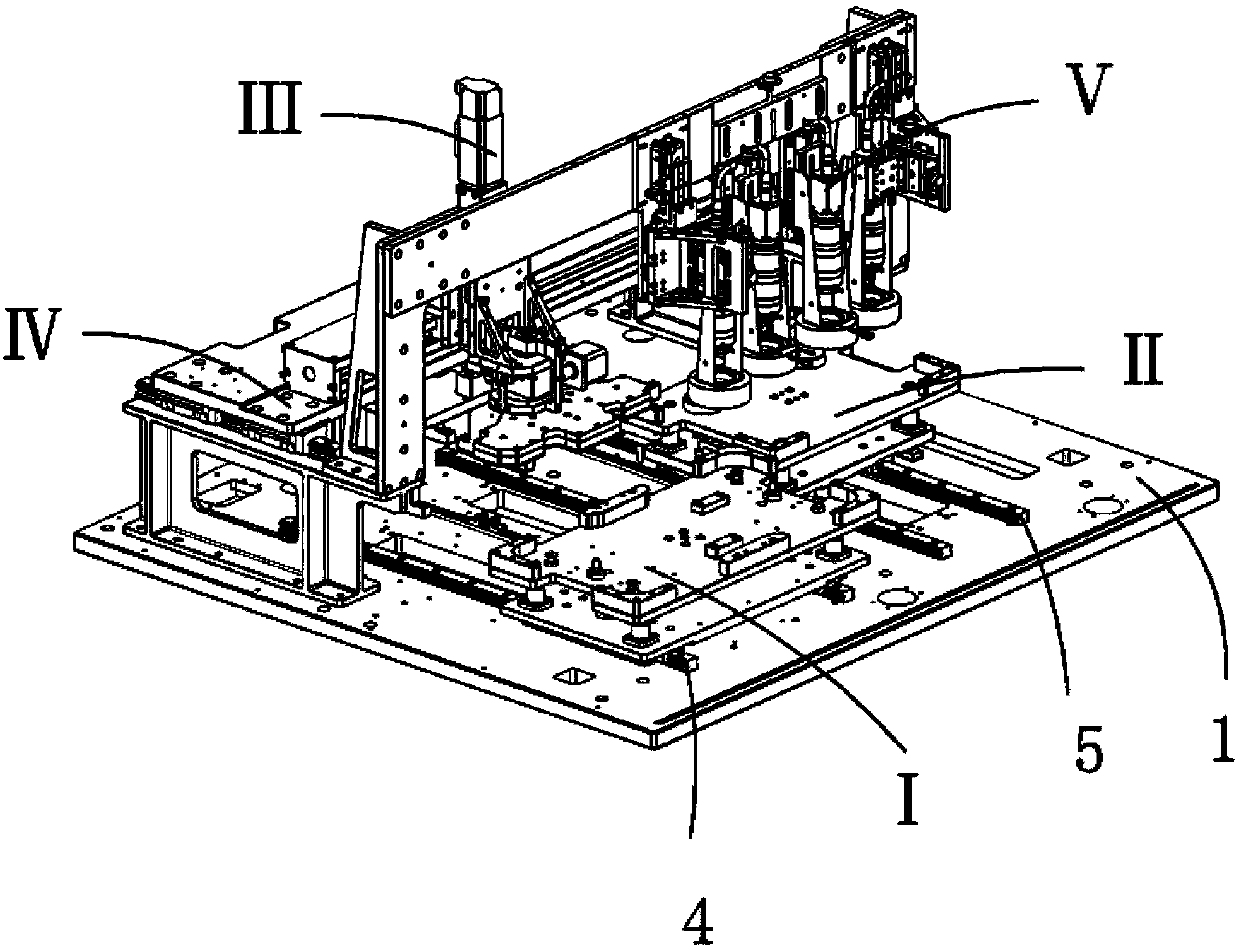

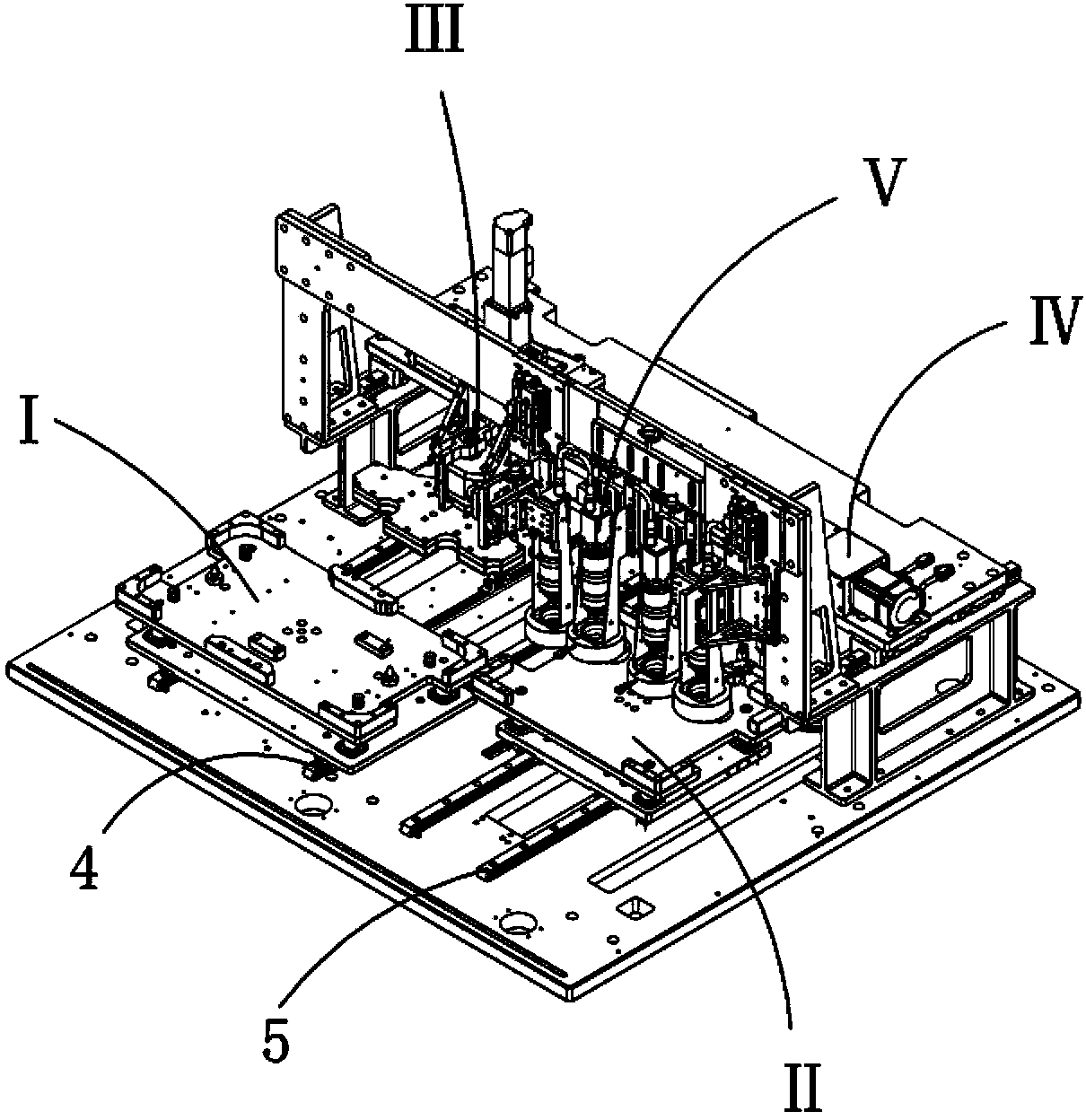

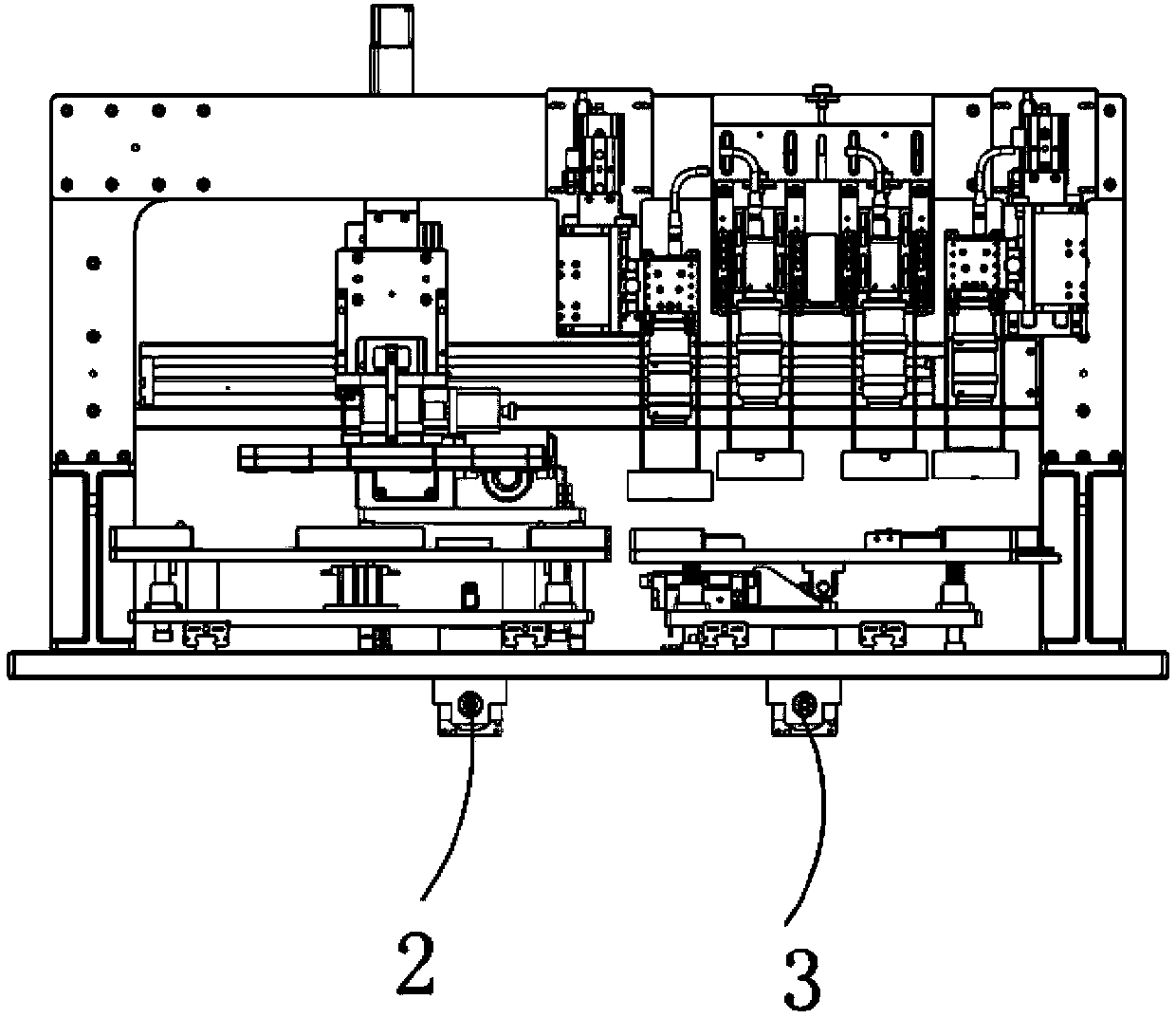

[0043] Examples, see attached Figure 1~3 , a laptop battery installation machine, it includes a large base plate 1, carrier mechanism I, carrier transport mechanism II, suction plate mechanism III, transport mechanism IV, calibration mechanism V and battery, the bottom of the large base plate is equipped with a motor a2 and motor b3, a slide rail assembly a4 and a slide rail assembly b5 are installed on the large base plate; a carrier mechanism is installed on the slide rail assembly a, and the carrier mechanism is connected with the screw mandrel of the motor a; the slide rail The carrier transport mechanism is installed on the component b, and the carrier transport mechanism is connected with the screw rod of the motor b; the transport mechanism is installed on the large base plate through the mounting seat; the suction plate mechanism is installed on the transport mechanism; the The calibration mechanism is mounted on the front of the mount.

[0044] See attached Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com