Temperature control switch automatic assembly riveting machine

A temperature-controlled switch and automatic assembly technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of inaccurate installation position of heat-sensitive metal sheets, low processing safety, and low work efficiency, so as to prevent personal injury, The installation position is accurate and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

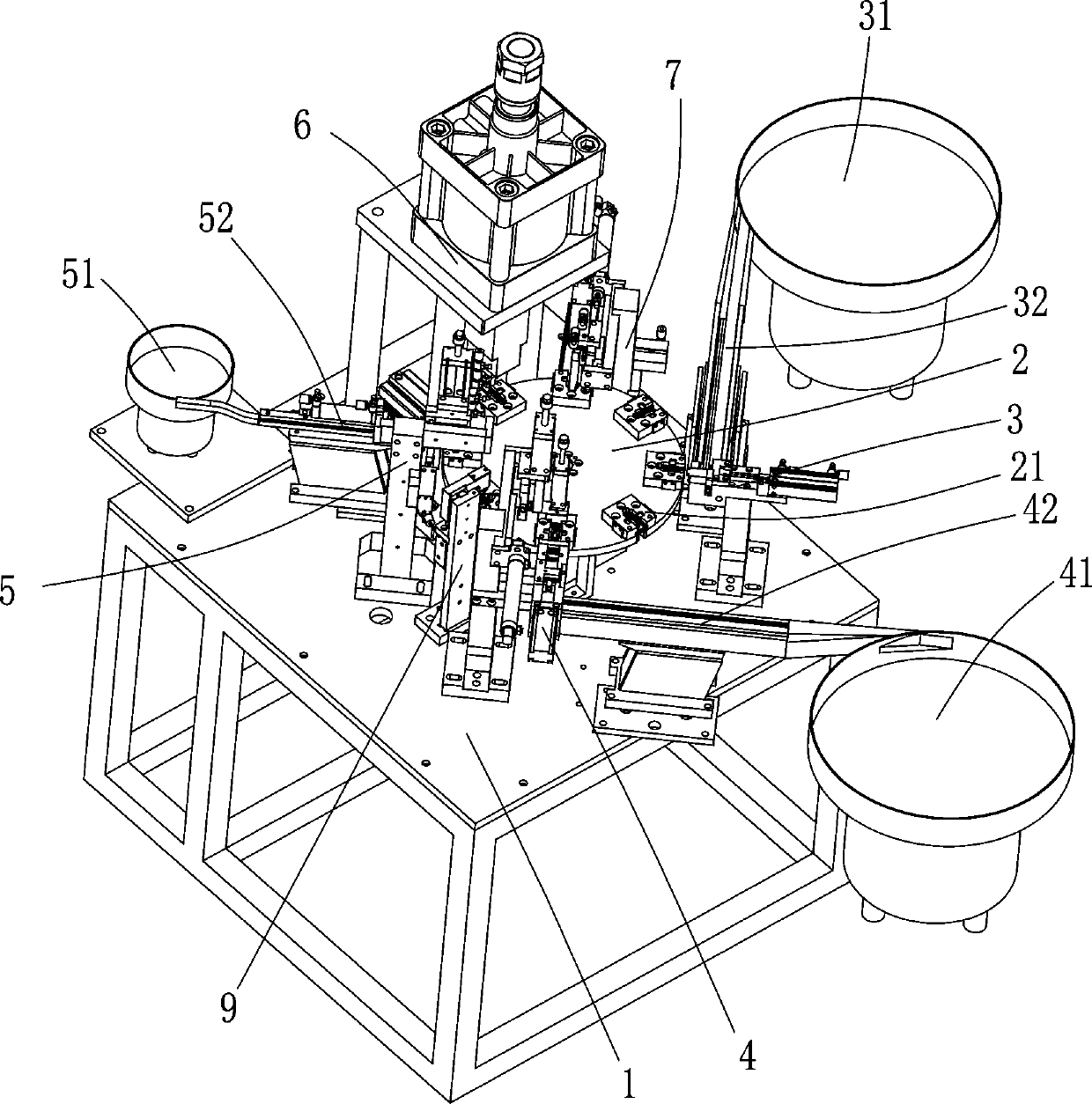

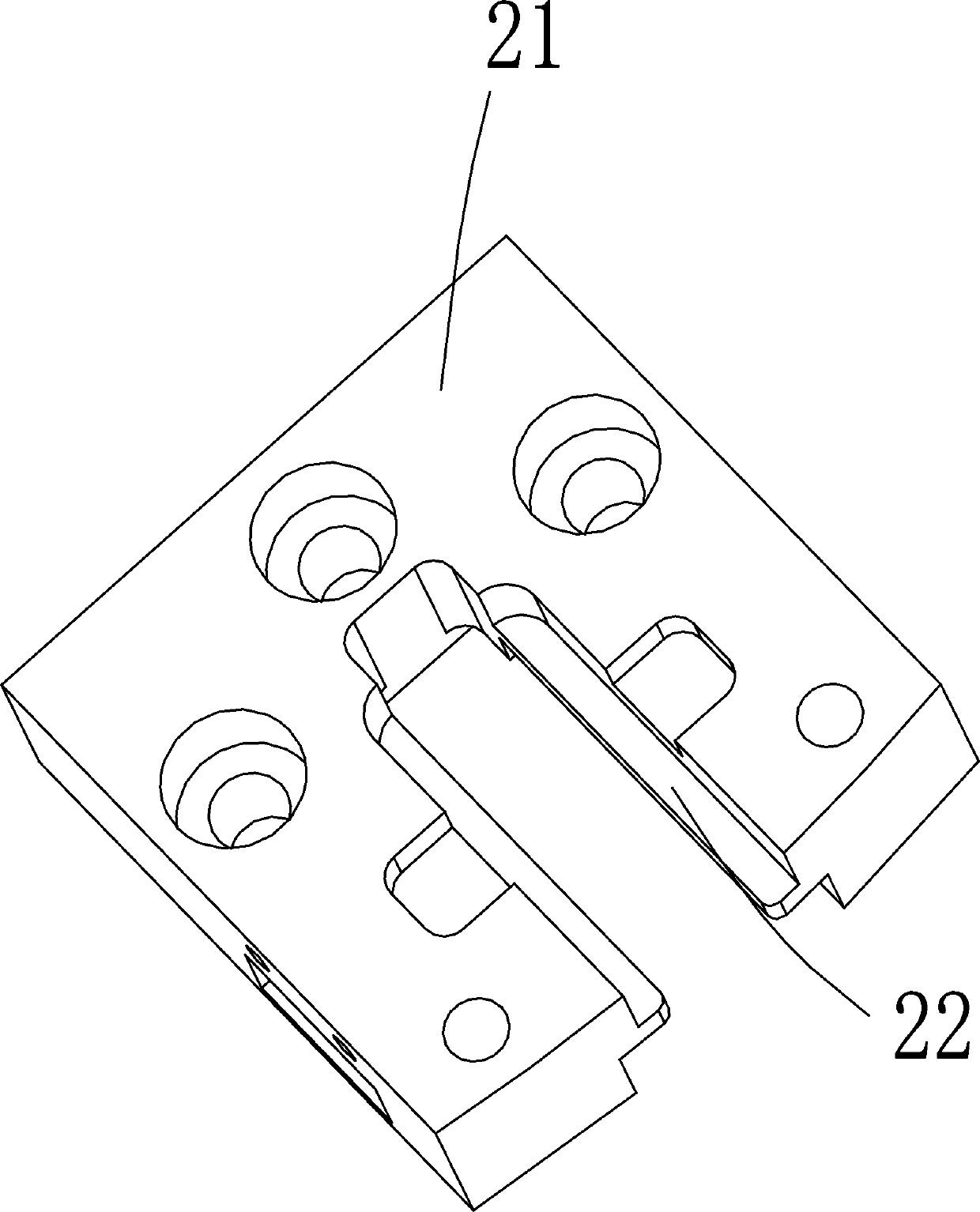

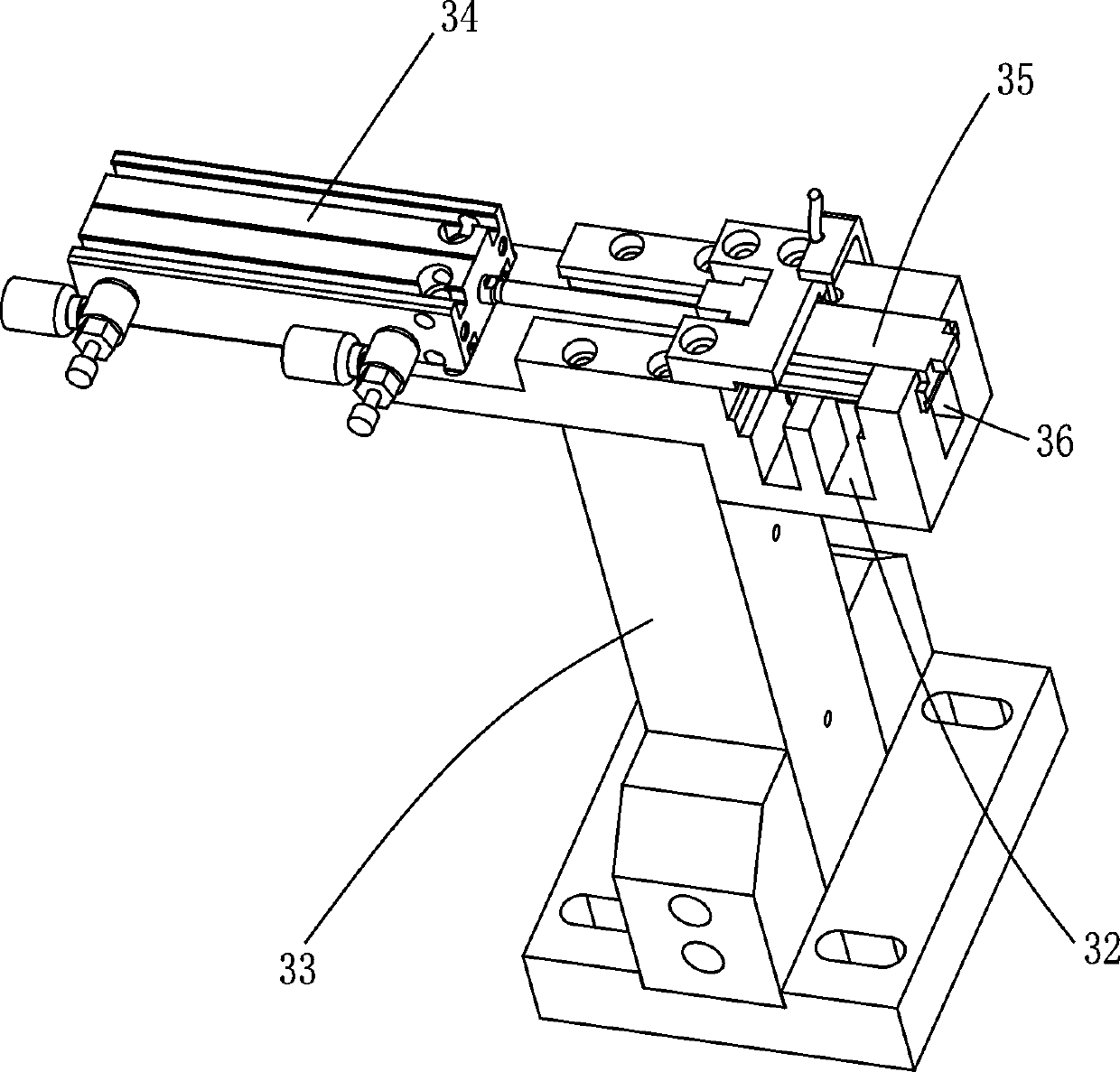

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 10 , a temperature-controlled switch automatic assembly riveting machine, including a base 1 and a rotating disk 2, the rotating disk 2 is rotatably arranged on the base 1, and the rotating disk 2 is sequentially arranged on the base 1 The temperature control switch base feeding device 3, the heat-sensitive metal sheet feeding device 4, the riveting sheet feeding device 5, the riveting device 6 and the feeding device 7, the rotating disk 2 is evenly provided with a number of positioning seats 21, the The positioning seat 21 is provided with a discharge groove 22 opening toward the outer side of the rotating disk 2 . This kind of automatic assembly riveting machine drives the positioning seat to rotate through the rotating disc, and the temperature control switch base is sent into the discharge groove of the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com