Sleeve type high-temperature and high-pressure resistant extracting pool and external member used for solvent extraction

An extraction pool and high-temperature-resistant technology, which is applied in solvent extraction, chemical instruments and methods, and separation methods, can solve problems that cannot be applied and are not conducive to extraction and analysis of trace samples, and achieve simplified processing, easy inertization, and materials used. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

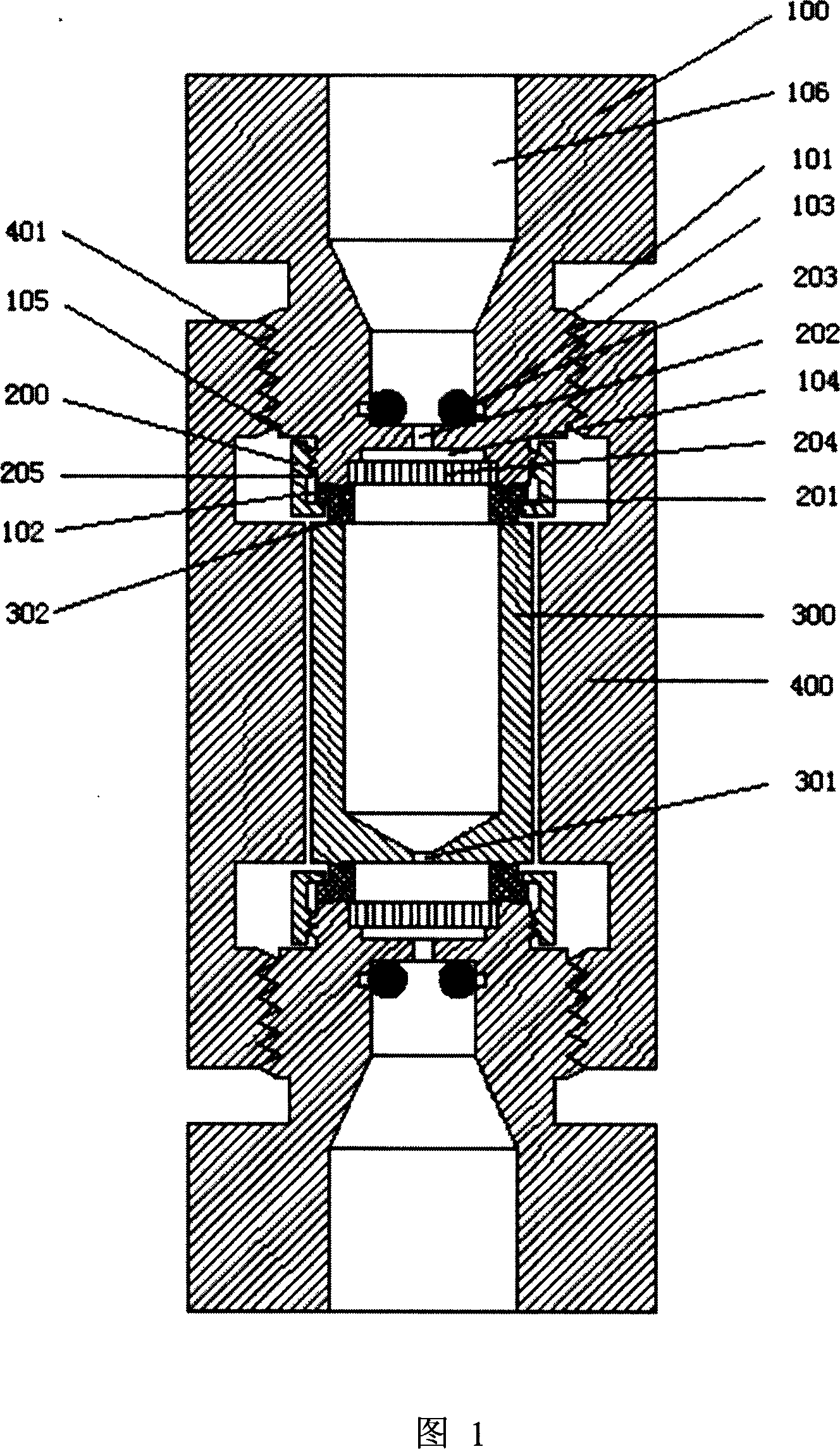

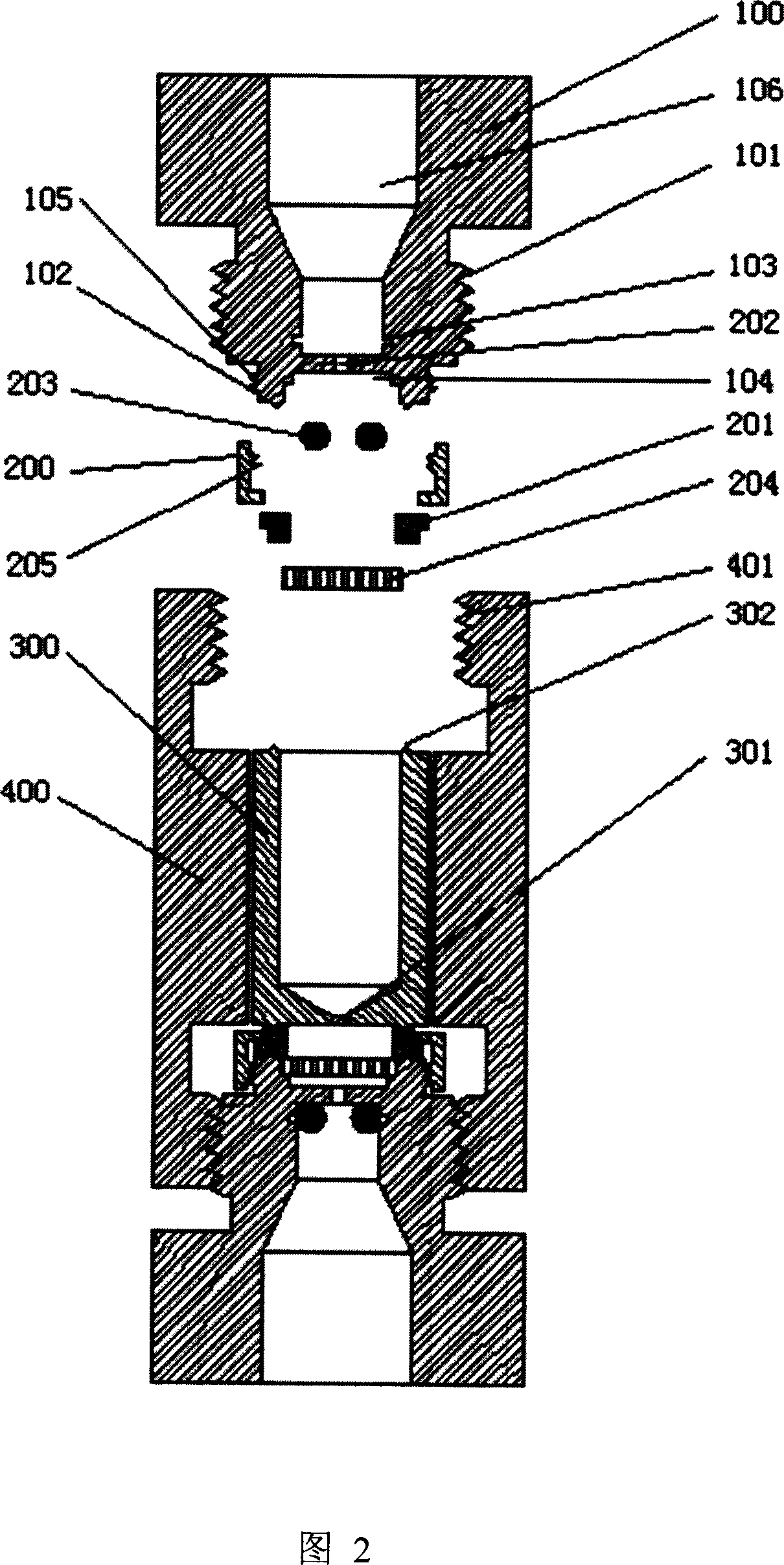

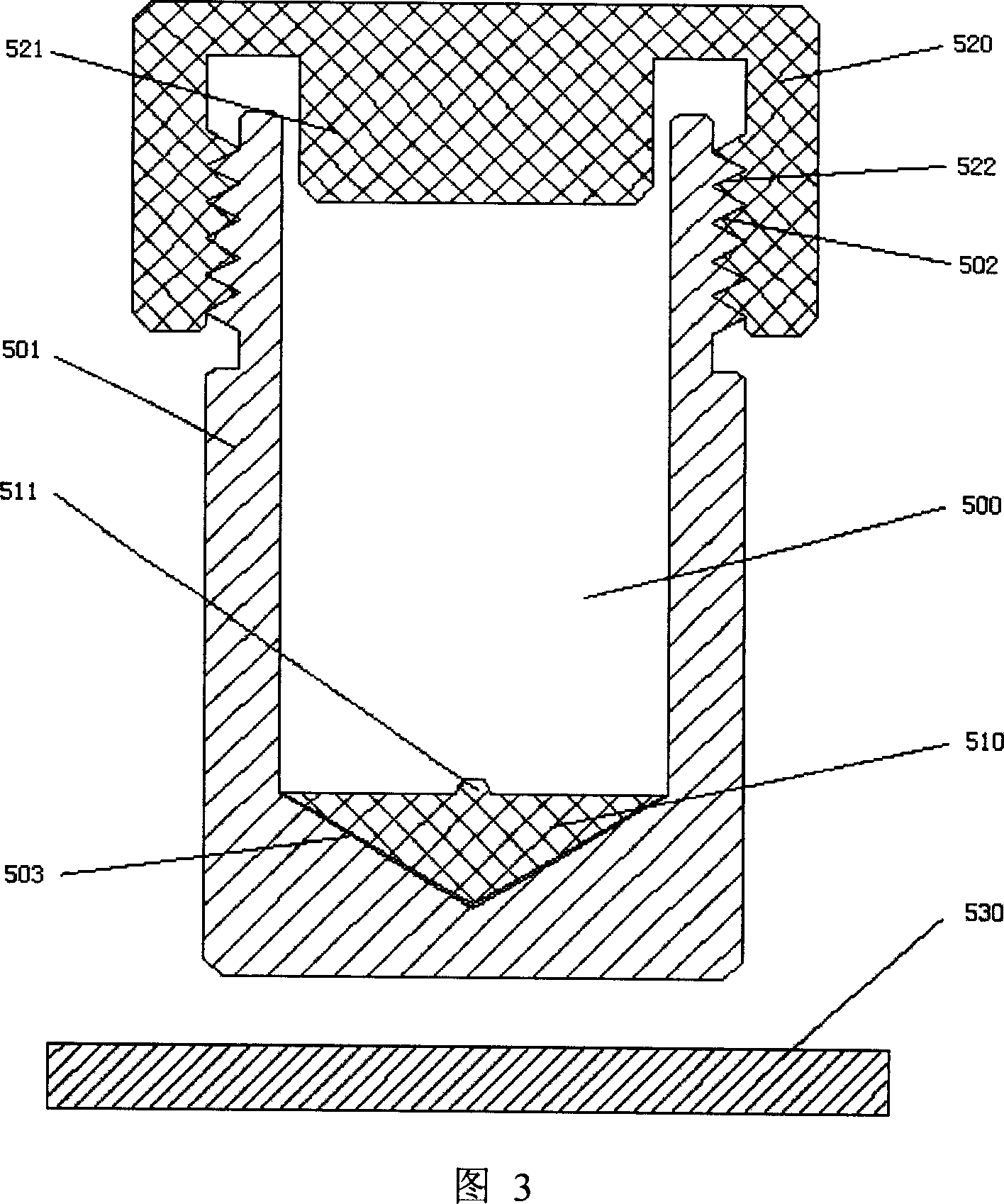

[0042] Referring to Fig. 1, Fig. 2 and Fig. 3, an extraction cell that can carry out solvent extraction of organic matter in solid or semi-solid samples under high temperature and high pressure mainly consists of an extraction cell pressure cap 100, a sealing ring pressure cap 200, a sample The pool 300, the sample pool fixing sleeve 400, and the sealing kit 500 used for filling samples in the sample pool and sealing for storage are composed of five parts.

[0043] 1) The pressure cap of the extraction tank is made of stainless steel, and the lower end has a sealing knife edge 102, which can be crimped and sealed with the sealing ring 201;

[0044] The upper end of the pressure cap of the extraction cell has a guiding and positioning cone groove 106, which is used for automatic positioning when the external solvent conduction joint is inserted into the pressure cap of the sample cell to achieve static pressure sealing. There is a '○' ring groove 103 at the lower end of the con...

Embodiment 2

[0062] Referring to Fig. 1, Fig. 2 and shown in Fig. 3, a kind of telescopic micro-extraction cell that can be combined with gas chromatography to carry out on-line detection, the cell body adopts the same design and material as in Example 1, and the size of the sample cell is an inner diameter of 2 -5mm, length 3-10mm, maximum working pressure 20Mpa, maximum working temperature 200℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com