Robot

A technology of robots and dual steering gears, applied in manipulators, motor vehicles, building structures, etc., can solve the problems of high risk factor, difficult construction, high labor cost, etc., achieve good shock absorption performance, safe and reliable design, and promotion value high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

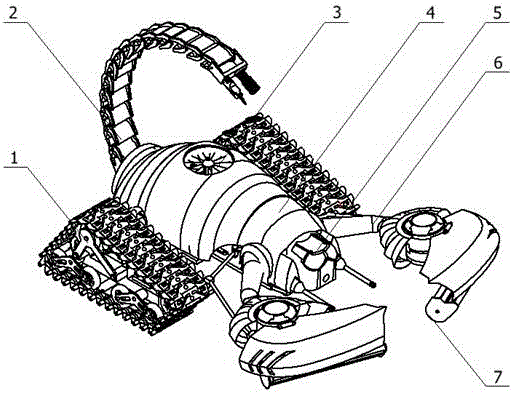

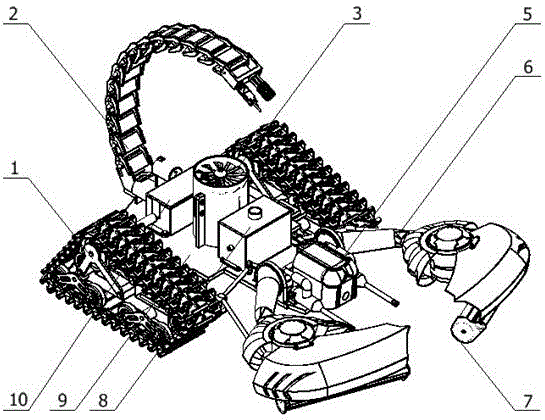

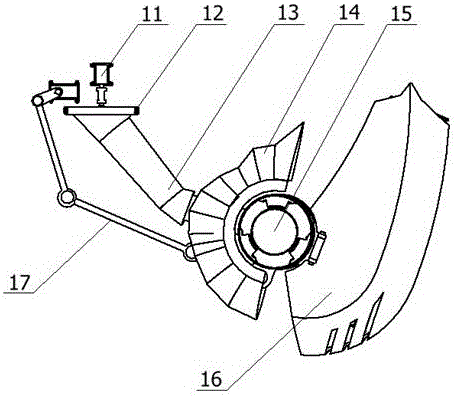

[0049] Embodiment 1: as Figure 1-14 As shown, a robot includes a secondary shock-absorbing triangular crawler 1, a duct adsorption device 3, a casing 4, a head spraying device 5, a double steering gear mechanical arm 6, a coating device 7, a charging box 8, and a bottom plate 9 , dual-motor differential device 10;

[0050] The head spraying device 5 is installed on the front end of the base plate 9, the left and right double steering gear mechanical arms 6 are respectively installed on both sides of the front end of the base plate 9 and a coating device 7 is installed on the double steering gear mechanical arms 6, and the charging box 8 is installed on the base plate 9 neck, the duct adsorption device 3 is installed on the middle part of the base plate 9 through bolt connection, the dual-motor differential device 10 is installed on the abdomen of the base plate 9 through bolt connection, and the secondary shock-absorbing triangular track 1 is installed on the dual-motor diffe...

Embodiment 2

[0064] Embodiment 2: as Figure 1-14 As shown, a robot includes a secondary shock-absorbing triangular crawler 1, a duct adsorption device 3, a casing 4, a head spraying device 5, a double steering gear mechanical arm 6, a coating device 7, a charging box 8, and a bottom plate 9 , dual-motor differential device 10;

[0065] The head spraying device 5 is installed on the front end of the base plate 9, the left and right double steering gear mechanical arms 6 are respectively installed on both sides of the front end of the base plate 9 and a coating device 7 is installed on the double steering gear mechanical arms 6, and the charging box 8 is installed on the base plate 9 neck, the duct adsorption device 3 is installed on the middle part of the base plate 9 through bolt connection, the dual-motor differential device 10 is installed on the abdomen of the base plate 9 through bolt connection, and the secondary shock-absorbing triangular track 1 is installed on the dual-motor diffe...

Embodiment 3

[0071] Embodiment 3: as Figure 1-14 As shown, a robot includes a secondary shock-absorbing triangular crawler 1, a duct adsorption device 3, a casing 4, a head spraying device 5, a double steering gear mechanical arm 6, a coating device 7, a charging box 8, and a bottom plate 9 , dual-motor differential device 10;

[0072] The head spraying device 5 is installed on the front end of the base plate 9, the left and right double steering gear mechanical arms 6 are respectively installed on both sides of the front end of the base plate 9 and a coating device 7 is installed on the double steering gear mechanical arms 6, and the charging box 8 is installed on the base plate 9 neck, the duct adsorption device 3 is installed on the middle part of the base plate 9 through bolt connection, the dual-motor differential device 10 is installed on the abdomen of the base plate 9 through bolt connection, and the secondary shock-absorbing triangular track 1 is installed on the dual-motor diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com