Laying device and using method thereof

A masonry and block technology, used in construction, building structure, construction material processing and other directions, can solve the problems of insufficient ash joints, thickness not meeting requirements, large quality fluctuations, etc., to achieve uniform thickness and operator technical skills. Depends on small, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the drawings and embodiments, but the content of the present invention is not limited to the following embodiments.

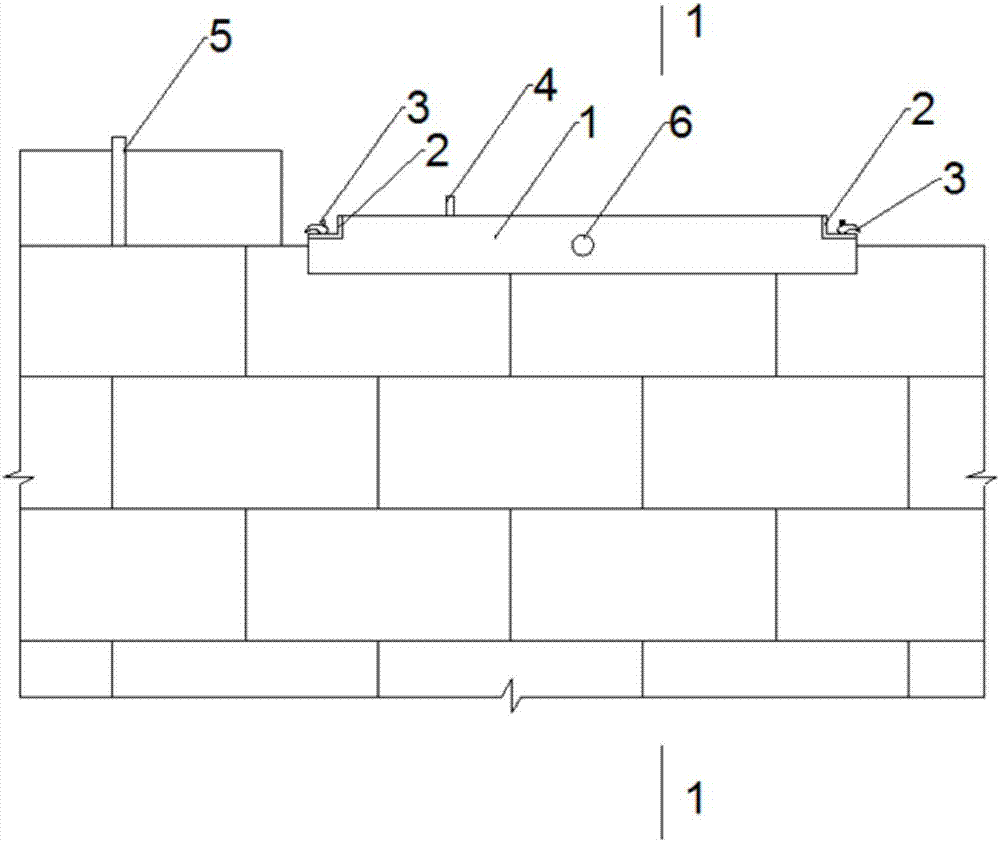

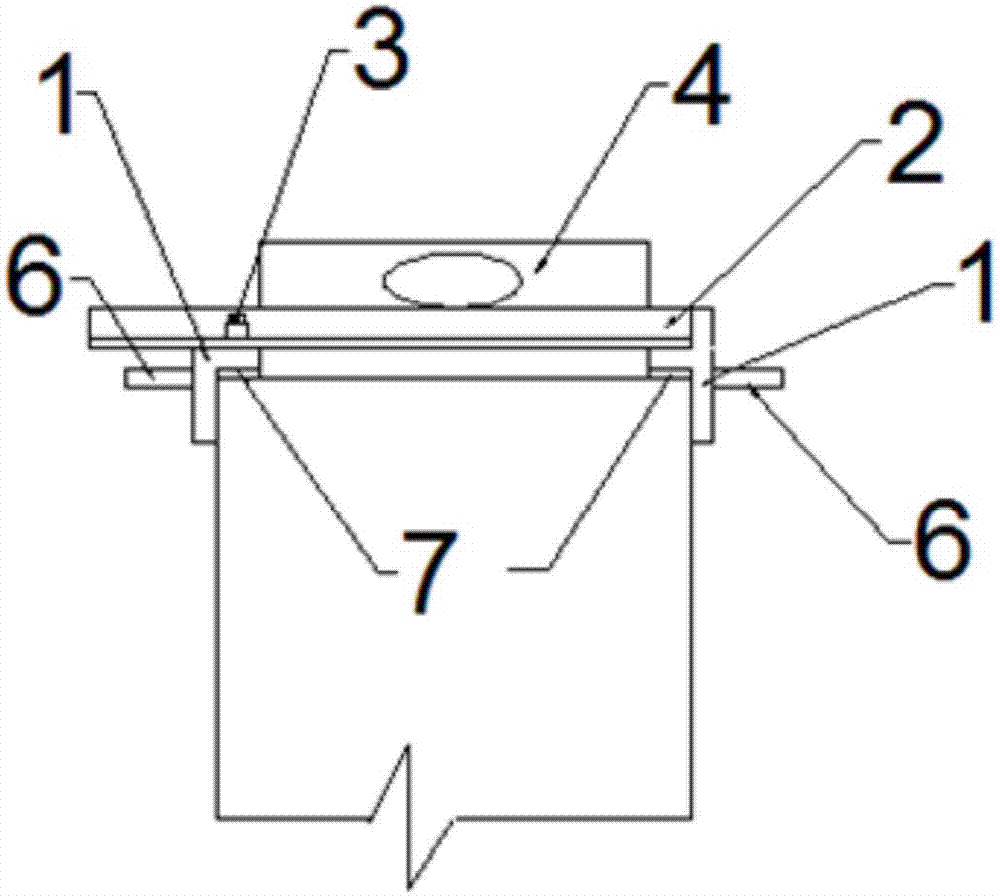

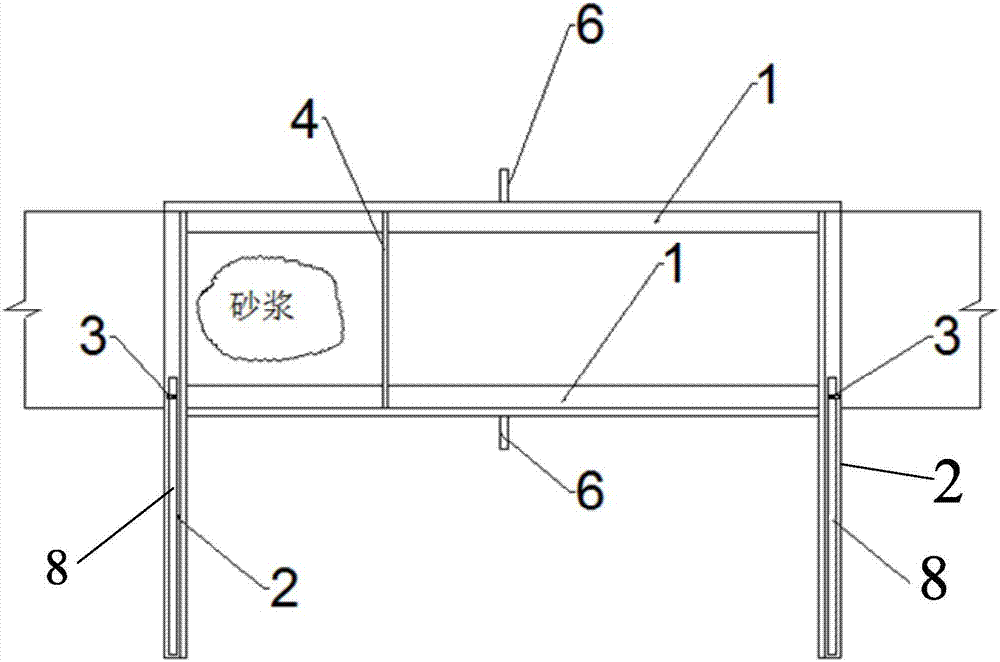

[0030] Such as Figure 1 to Figure 4 As shown, it is a schematic structural diagram of a masonry device provided by an embodiment of the present invention. It includes a horizontal mortar joint device and a vertical mortar joint device5.

[0031] The horizontal mortar joint device includes two oppositely arranged sliding rails 1, two first adjusting frames 2, two first fasteners 3, ash scrapers 4, two handles 6 and a wear-resistant layer 7. Two slide rails 1 are respectively arranged on both sides of the masonry along the horizontal direction of the masonry. The bottoms of the two slide rails 1 can slide in a horizontal direction relative to the masonry. Two sliding rails 1 are provided with sliding grooves on the inner side. The ash scraper 4 can slide in the horizontal direction in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com