Telescopic truss crossbeam and manufacture method thereof

A manufacturing method and telescopic technology, applied in truss bridges, manufacturing tools, erecting/assembling bridges, etc., can solve problems such as the influence of girder straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

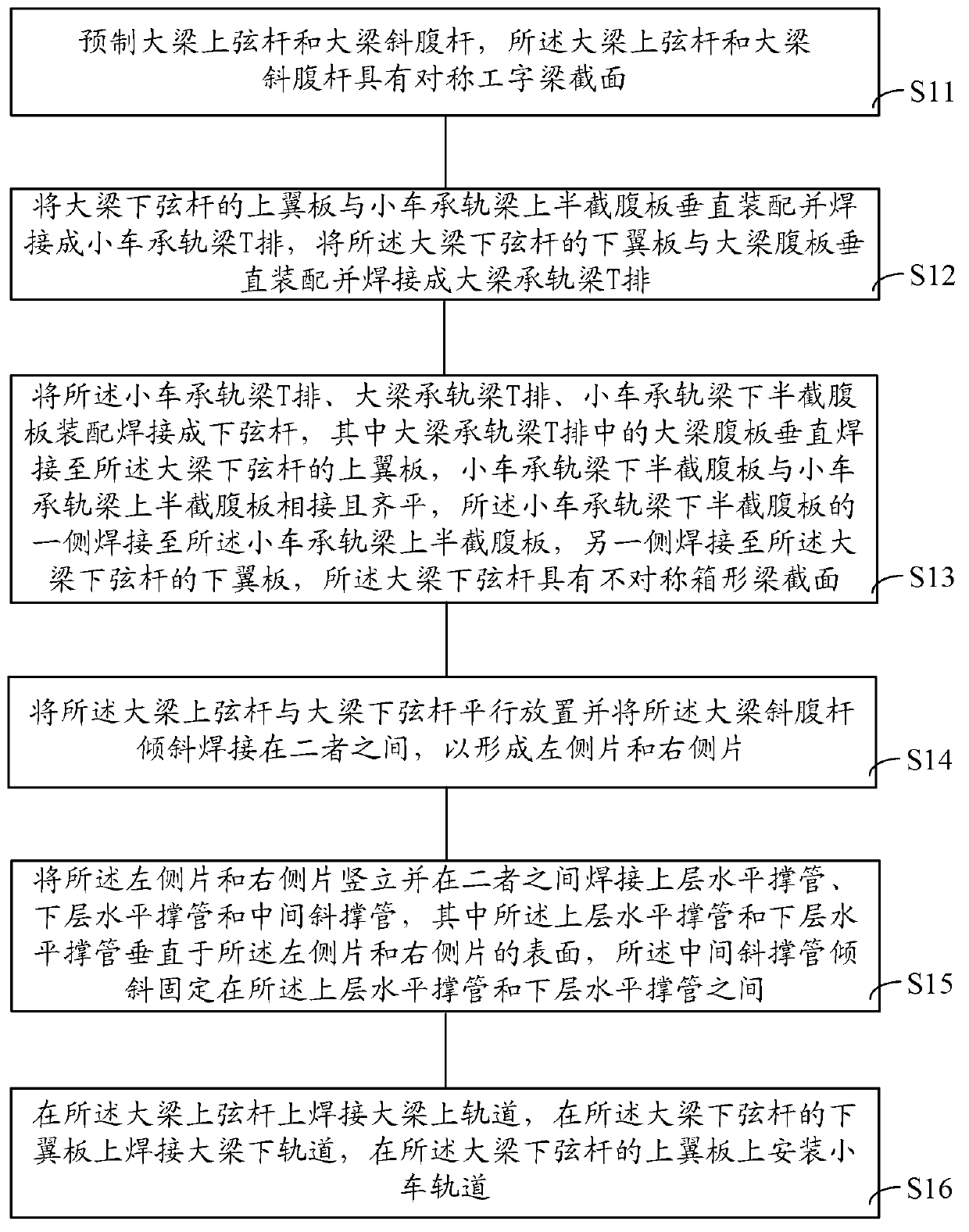

[0058] figure 1 The manufacturing method of the telescopic truss girder of this embodiment is shown, including:

[0059] Step S11, prefabricating the top chord of the girder and the diagonal web of the girder, the top chord of the girder and the diagonal web of the girder have a symmetrical I-shaped beam section;

[0060] Step S12, vertically assembling and welding the upper flange of the lower chord of the girder and the upper half of the web of the trolley rail girder to form a T row of trolley rail girders, vertically assembling and welding the lower flange of the lower chord of the girder with the web of the girder Chengda beam bearing beam T row;

[0061] Step S13, assembling and welding the T row of trolley rail girders, the T row of girder rail girders, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com