Alignment method of rolling mill archway

A rolling mill archway and deviation technology, which is applied in the field of rolling mill equipment installation and inspection, can solve the problems of complexity, incomplete alignment method and low reading accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

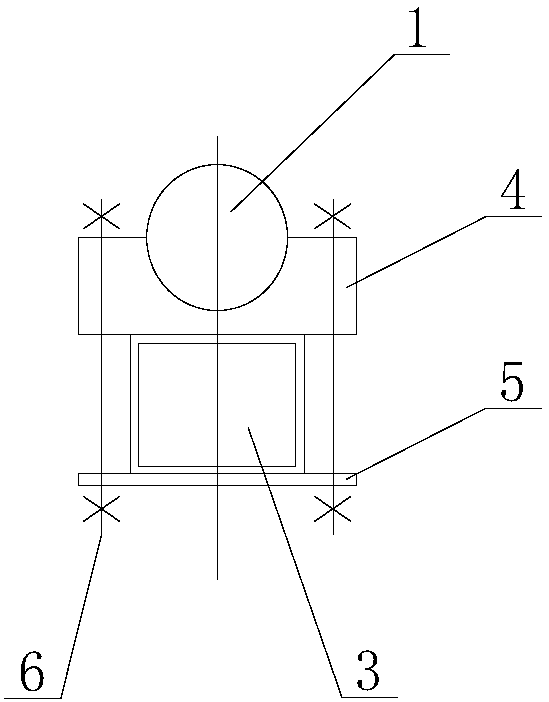

[0034] The present invention will be further described below in conjunction with accompanying drawing.

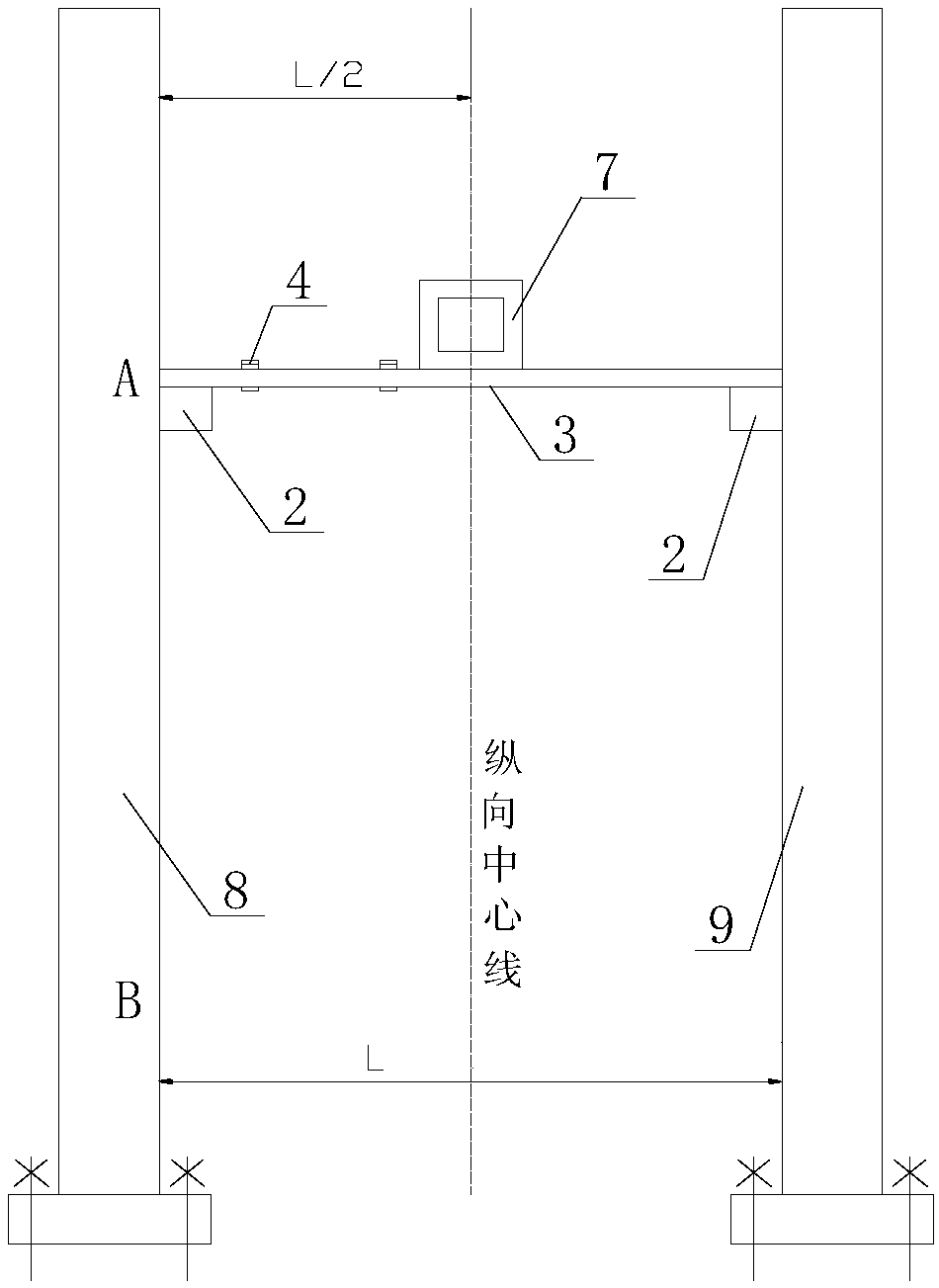

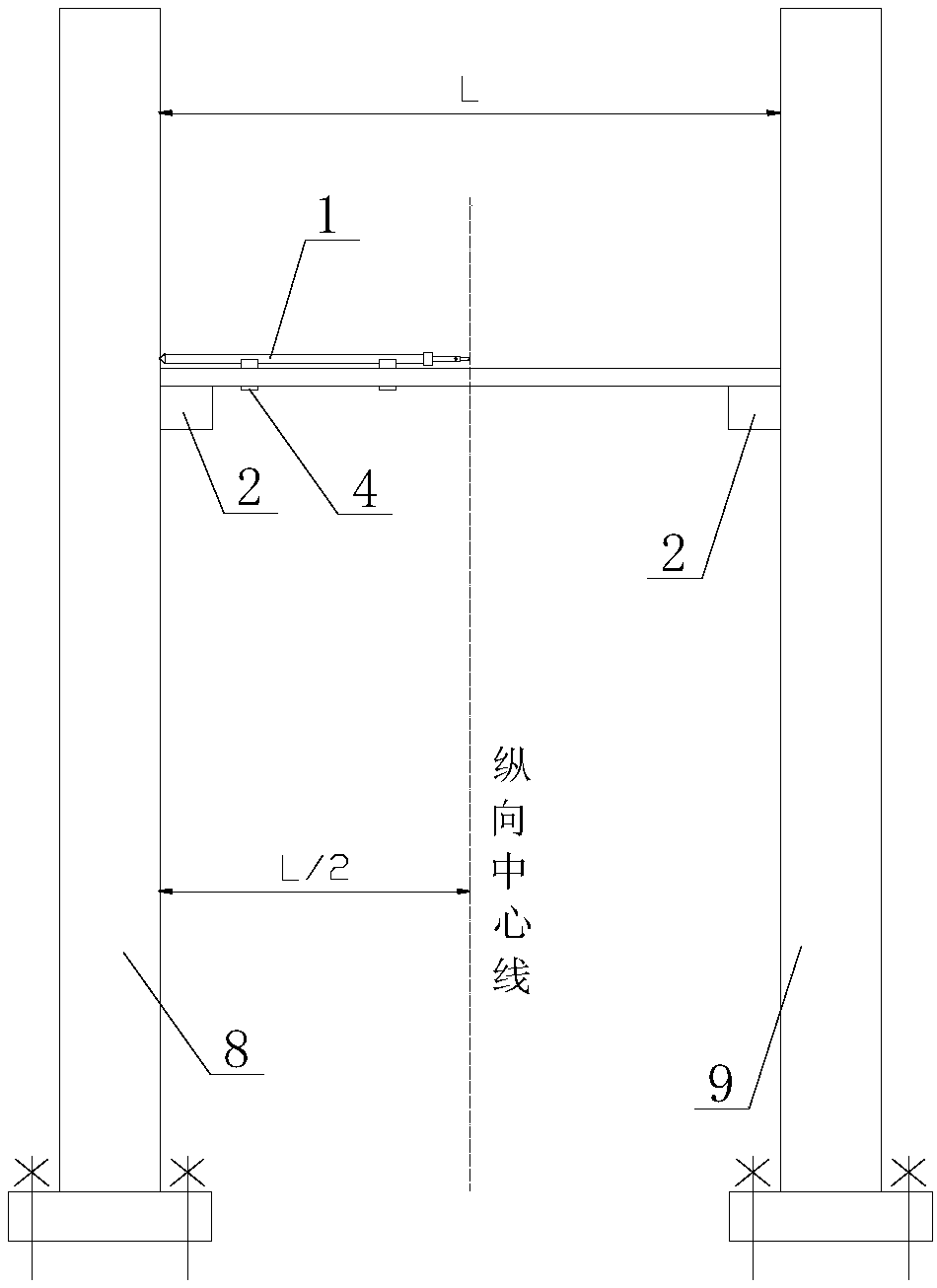

[0035] The rolling mill arch alignment method of the present invention includes longitudinal center deviation and verticality detection, lateral center deviation and verticality detection, and the two detections are carried out at the same time; the rolling mill arch is adjusted accordingly according to the detection results, and the detection feedback is performed, and the rolling mill arch is adjusted accordingly , until the corresponding technical requirements are met.

[0036] Among them, the longitudinal center deviation, verticality detection and adjustment include the following steps:

[0037] A. Tighten the anchor bolts of the rolling mill archway, for example, tighten the anchor bolts according to the 50% torque of the final anchor bolts. If the anchor bolts are not tightened, the value measured by the rolling mill archway will change after the anchor bolts are ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com