Steel latticed column homocentric-square-shaped concrete bearing platform combination type tower crane base structure and construction method

A technology of steel lattice column and tower crane foundation, which is applied in the direction of foundation structure engineering, underwater structures, artificial islands, etc., and can solve the problems of early insertion of vertical transportation in deep foundation pit construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

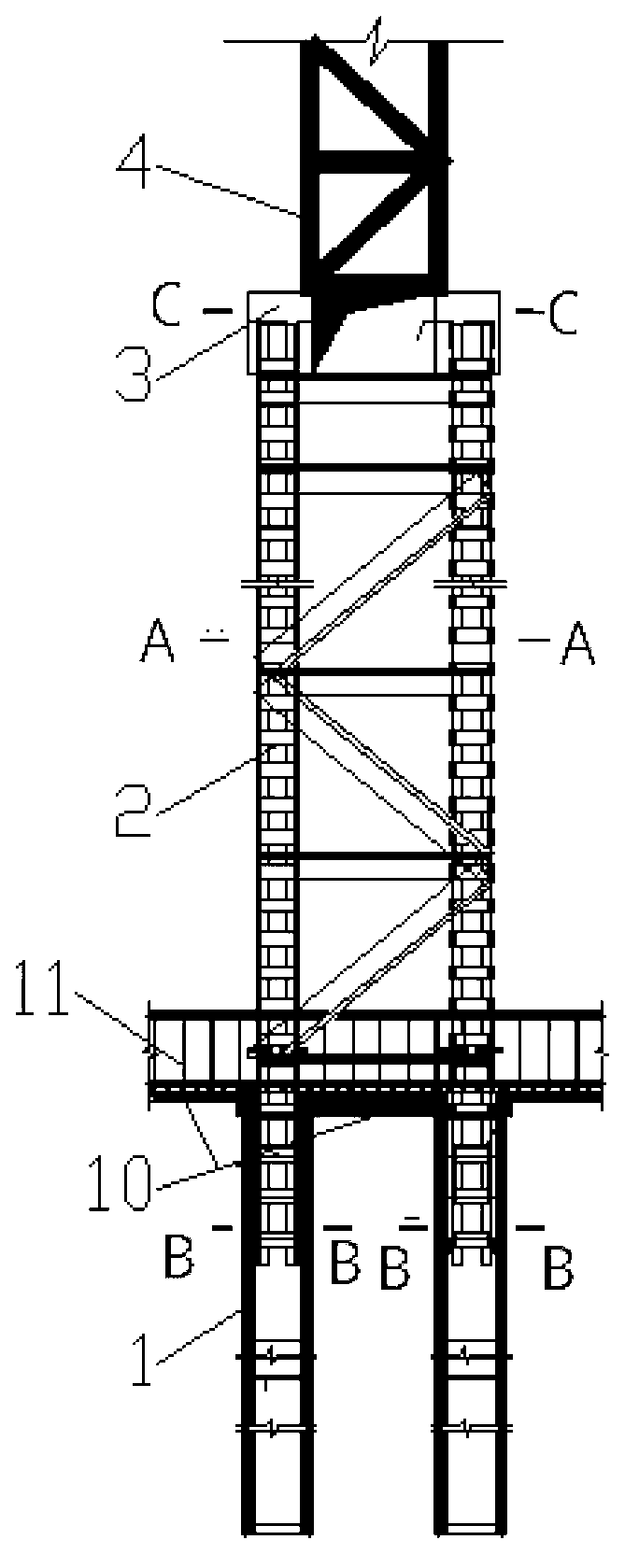

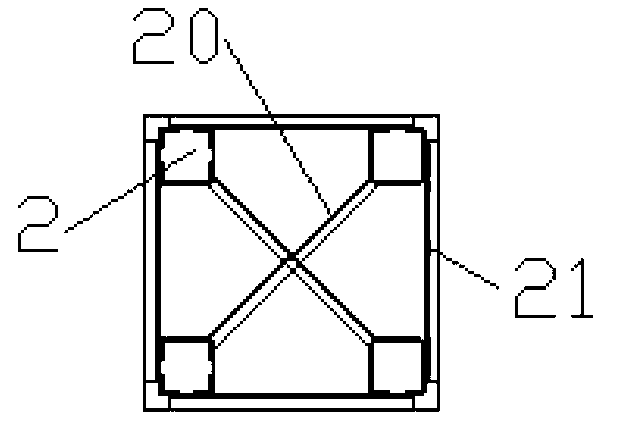

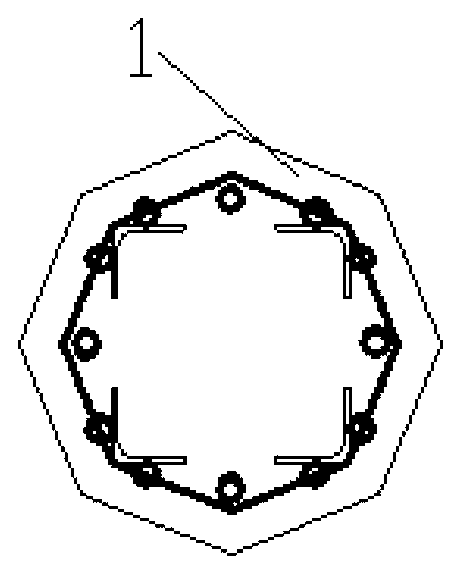

[0021] Such as Figure 1 to Figure 4 The combined tower crane foundation structure of the steel lattice column back type concrete cap, which includes four vertically arranged rectangular steel lattice columns 2, and horizontal scissor braces 20 and vertical scissor braces are arranged between the steel lattice columns. Scissor brace 21, the bottom of the steel lattice column is inserted into the bored pile 1, and the bored pile is arranged under the basement floor 11, and a concrete structure cap 10 is poured under the basement floor 11, and the steel grid A back-shaped concrete cap 3 is poured on the top of the column, and the bottom of the tower crane is installed on the back-shaped concrete cap 3 .

[0022] The cross section of the steel lattice column is square. The side length of the cross-section of the steel lattice column is 480 mm, and the diameter of the steel bar used in the bored pile is 18 mm.

[0023] In addition, the construction method of the steel lattice co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com