Cushion block for controlling floor thickness

A technology of thickness control and spacers, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of difficult control of floor elevation and flatness, long construction period, labor-intensive, etc., so as to save construction procedures and manufacturing costs Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

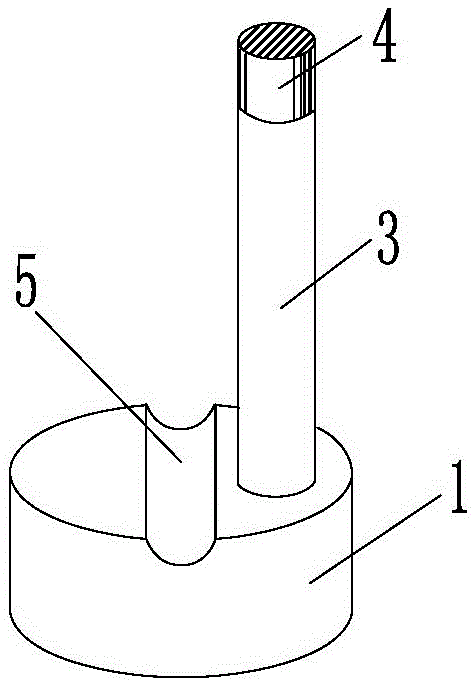

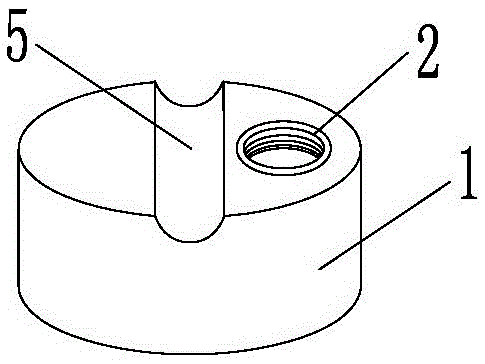

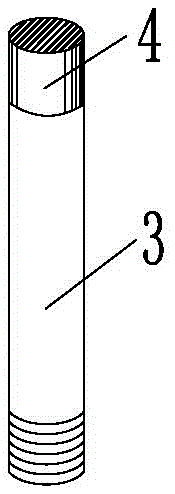

[0011] As shown in Figures 1 to 4, the structure of the present invention is that the concrete block 1 is provided with a through hole through up and down, and a nut 2 is embedded in the through hole. The lower end of the nut and the bolt 3 are sleeved, and the upper end of the bolt Placed above the nut, the upper end of the bolt is coated with a reflective paint layer 4, and the center of the upper surface of the concrete block is provided with a groove 5 outside the through hole.

[0012] The concrete block 1 is cylindrical.

[0013] The diameter of the concrete block 1 is greater than the height of the concrete block.

[0014] The groove 5 is semicircular.

[0015] The front opening of the groove 5 is placed at the center of the front side of the concrete pad, and the rear opening of the groove is placed at the center of the back side of the concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com