Backlight module frame preparation method

A backlight module and frame technology, applied in laser welding equipment, other manufacturing equipment/tools, optics, etc., can solve problems such as insufficient flatness of the joint surface, affecting the dimensional accuracy of the metal frame, and achieve the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

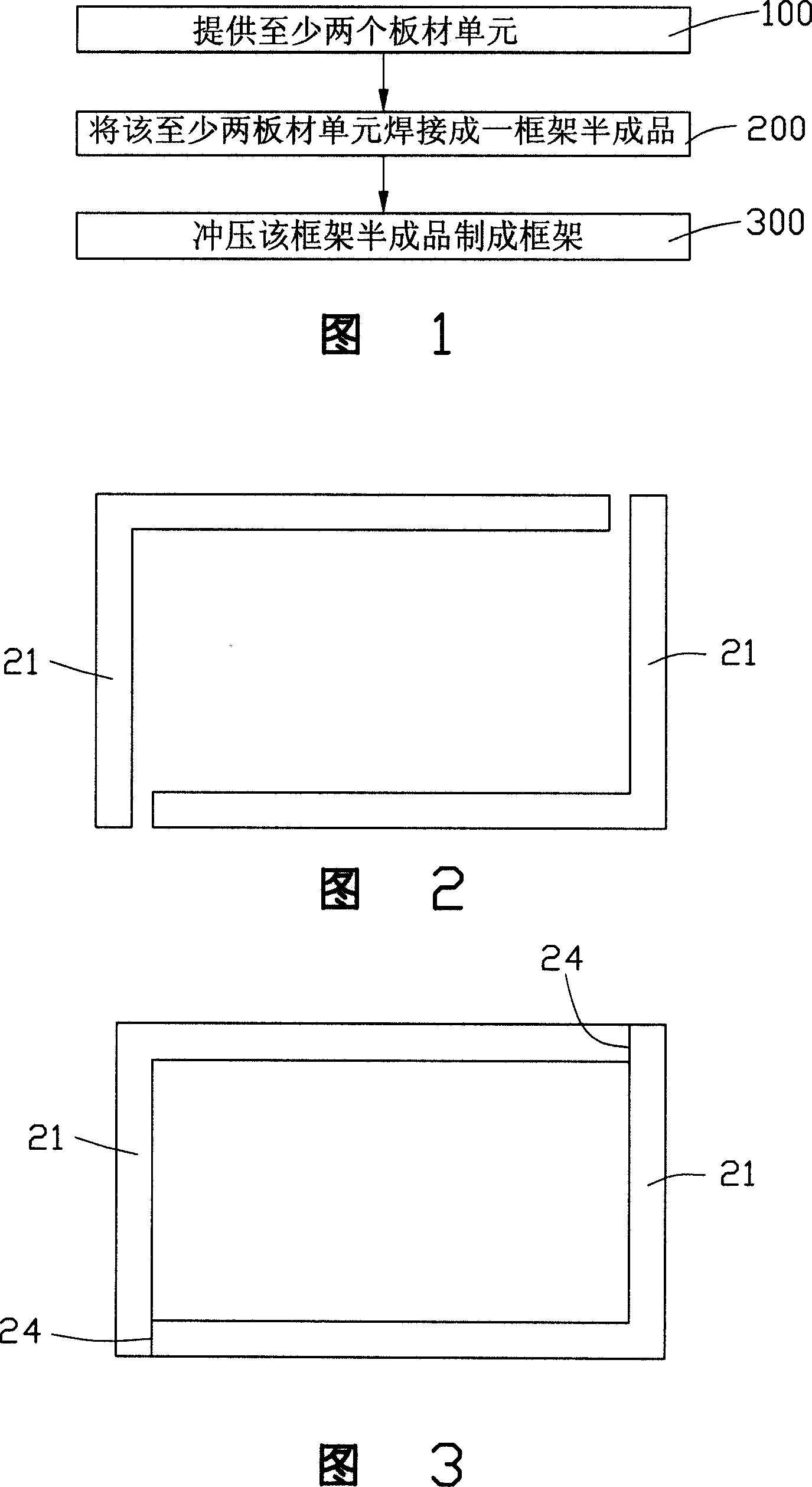

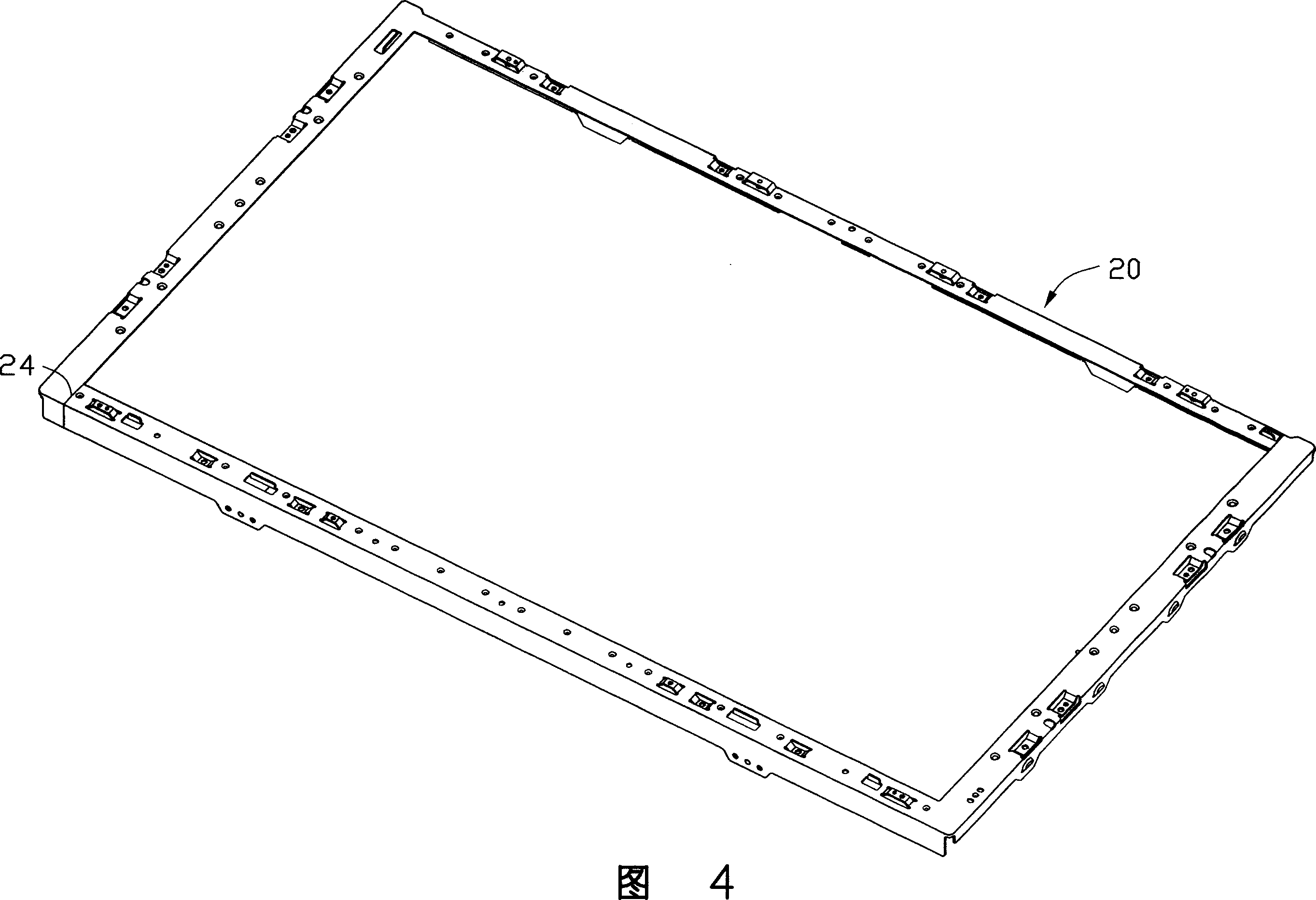

[0017] Referring to FIG. 1, the present invention provides a method for preparing a backlight module frame, which includes the following steps:

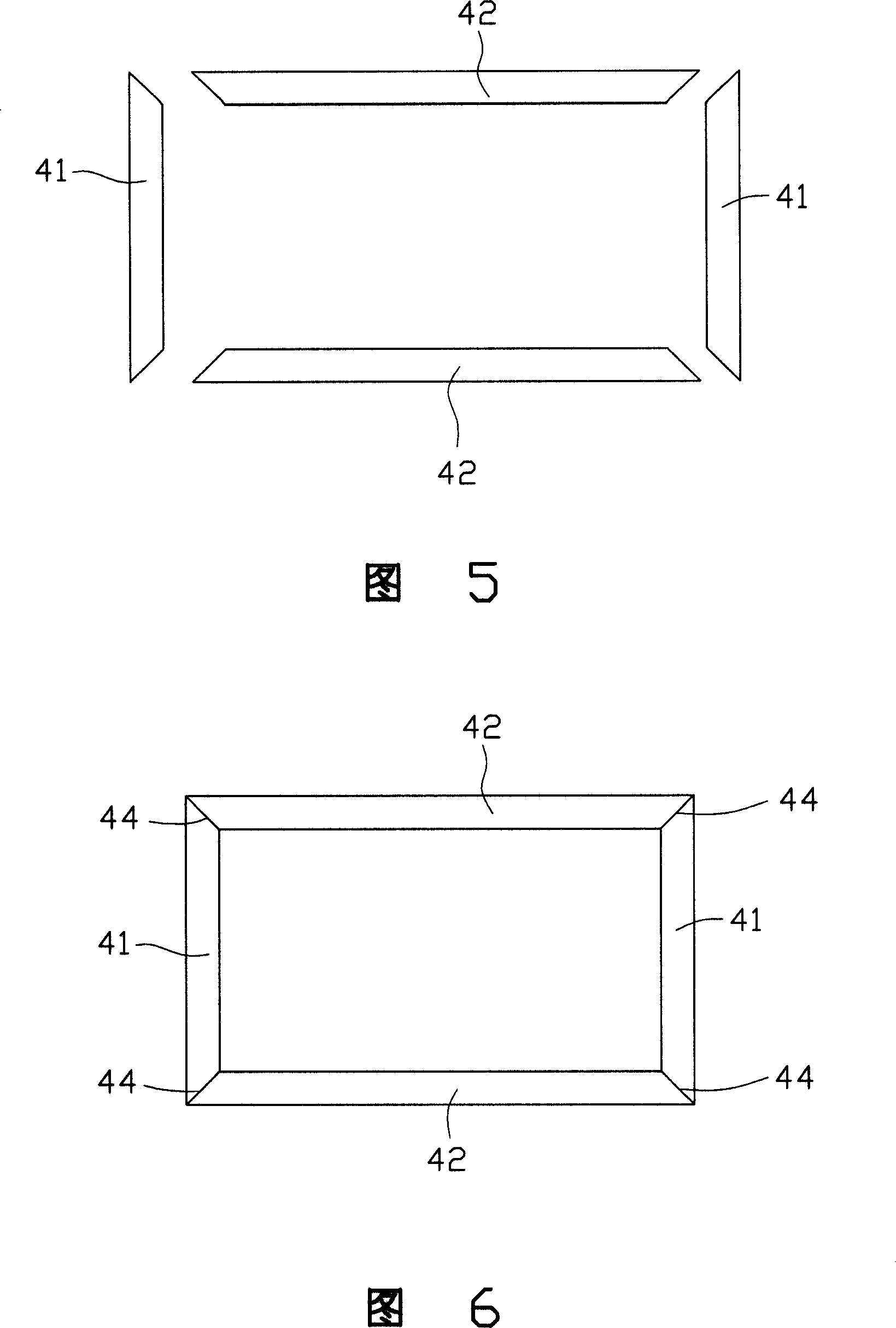

[0018] Step 100 is to provide at least two plate units. The outer shape of the plate unit can be long or L-shaped, which can be formed by cutting metal plates by a punch. The plate unit is made of metal material. The multiple plate units can be spliced into a frame shape, and the width and length of the plate units are slightly larger than those of the designed frame. The main purpose is to consider the appropriate area required for the subsequent stamping steps. In addition, in order to increase the joint strength of the subsequent welding, the ends of the plurality of plate units can be arranged inclined.

[0019] Step 200 is to weld the at least two plate units into a frame semi-finished product. The edges of the plurality of plate units to be welded are in flush contact, and then at least one laser beam is used to weld the joints o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com