Unit curtain wall system with cantilevered glass flank and opening window

A unit curtain wall and window opening technology, which is applied to walls, building components, buildings, etc., can solve the problems of uneven and beautiful curtain wall facades, poor control accuracy, and inconvenient installation of overhanging glass wings, so as to reduce processing procedures, High installation accuracy and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

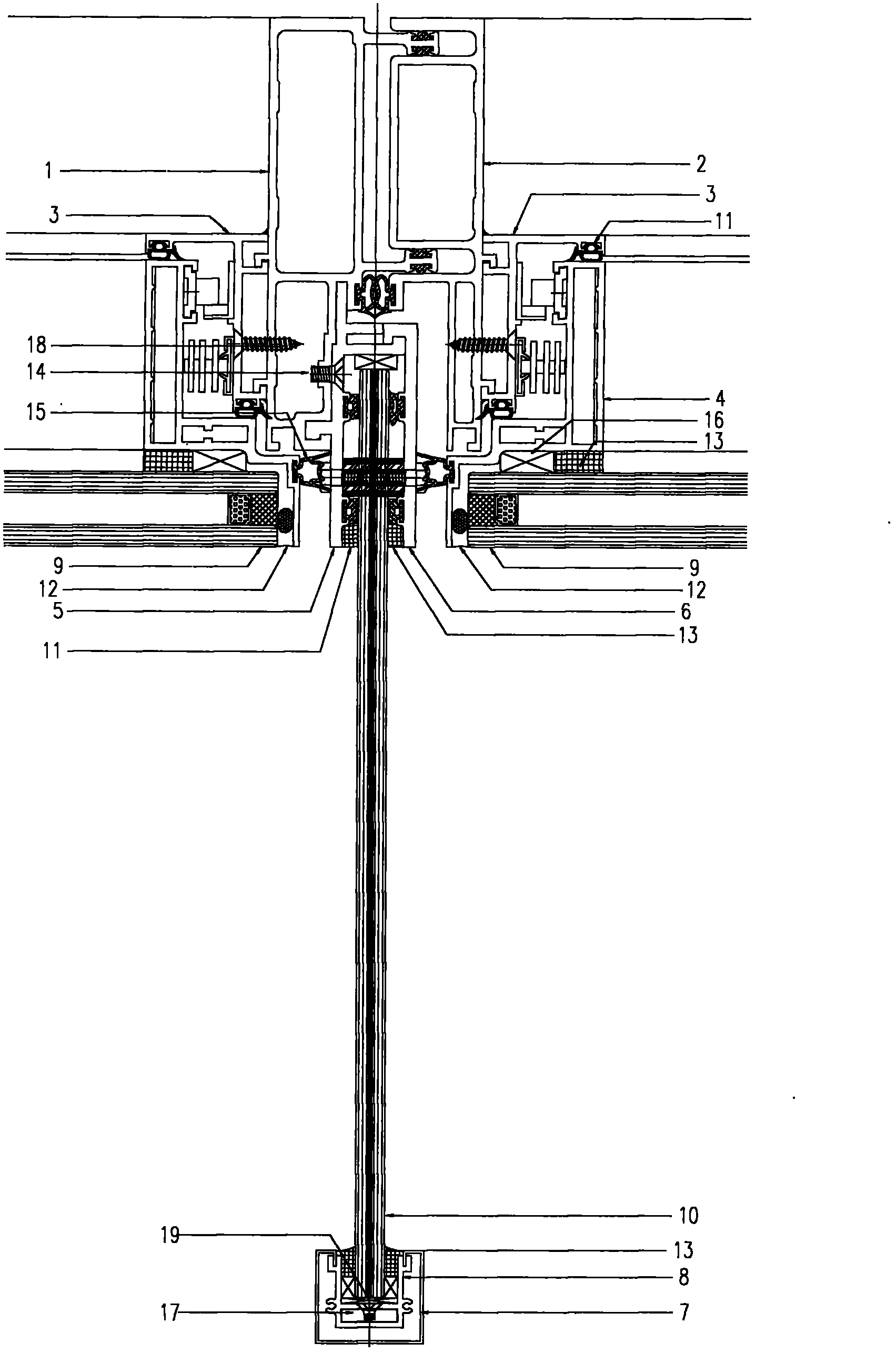

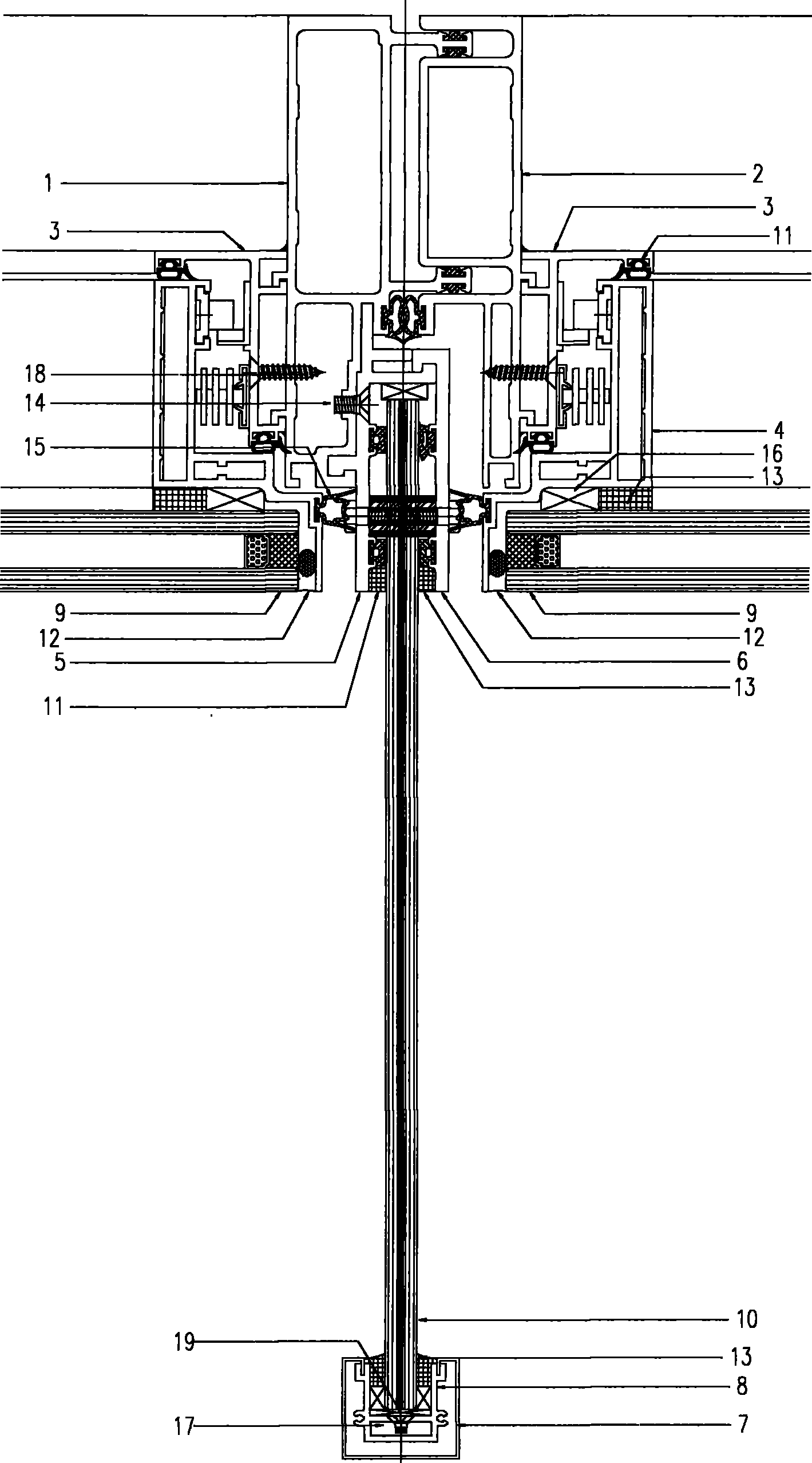

[0020] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

[0021] Please refer to the attached figure 1 , the curtain wall system of glass wing overhanging with open window unit in this embodiment includes: 1 unit public column, 2 unit female column, 3 aluminum alloy window frame material, 4 aluminum alloy window sash material, 5 aluminum alloy connector, 6. aluminum alloy Gusset plate, 7 stainless steel plate (1.5mm thick), 8 glass edge protection, 9 curtain wall glass, 10 cantilever glass, 11 EPDM adhesive strip, 12 weather-resistant sealant, 13 structural adhesive, 14 countersunk head stainless steel screw, 15 stainless steel bolt assembly , 16 double-sided stickers, 17 aluminum alloy ferrule, 18 stainless steel countersunk self-tapping screws, 19 flexible pads;

[0022] Among them, the aluminum alloy window frame material 3 is buckled on the male and female columns 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com