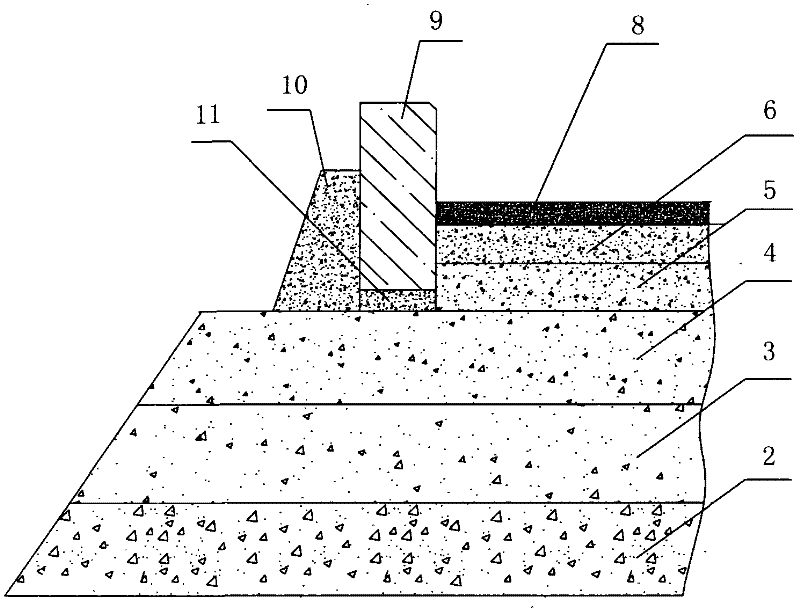

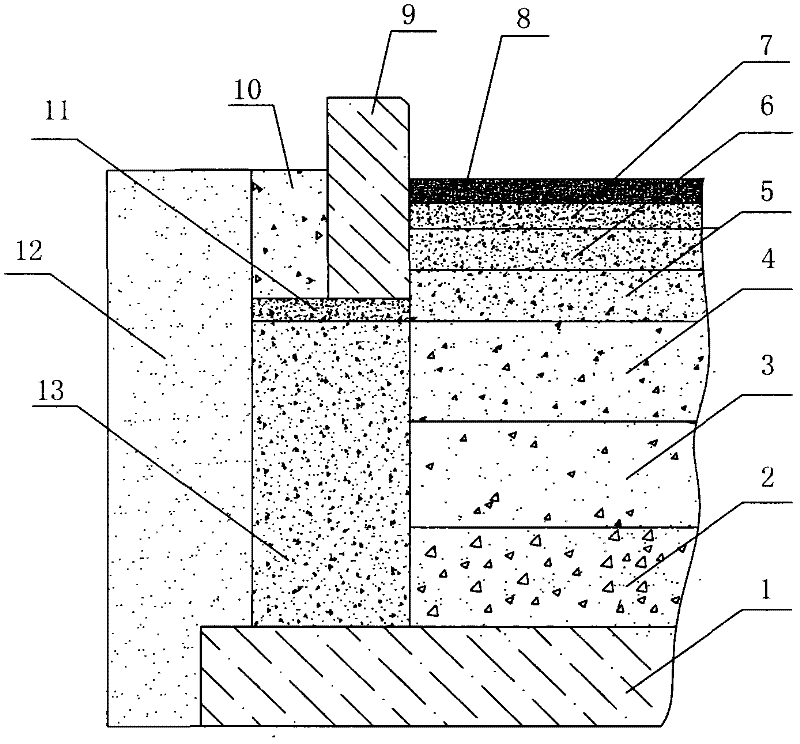

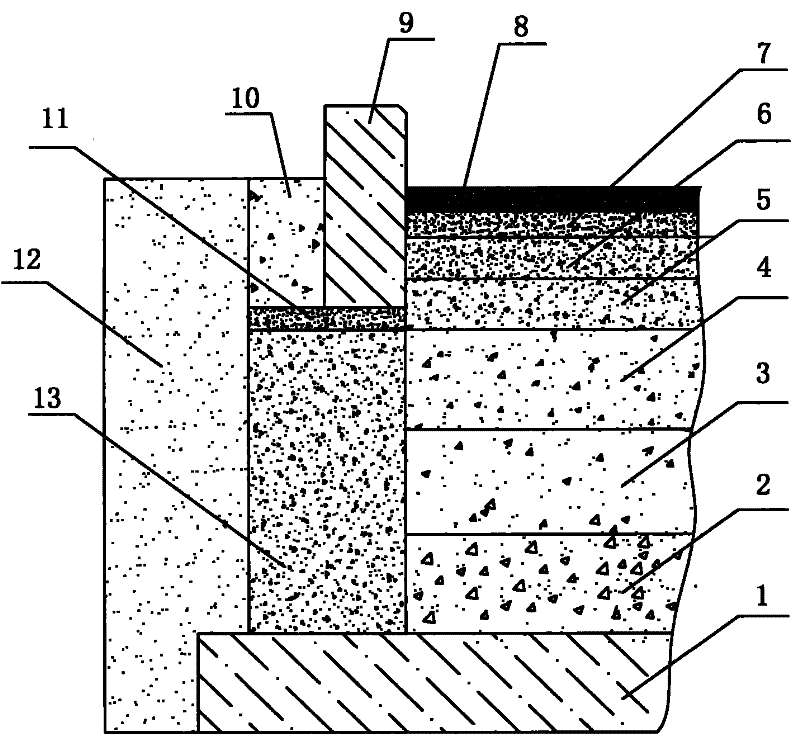

Construction method for road base concrete side mold

A technology of road base and construction method, applied in the directions of roads, roads, buildings, etc., can solve the problems of inability to guarantee the compaction on both sides of the road base, inaccurate elevation control, lower elevation at the edge, etc. The effect of workload, avoidance of road water accumulation, and improvement of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] ①Construction preparation

[0042] The lower bearing layer of A has been checked and accepted by all parties.

[0043] B Prepare the concrete side formwork for the road base, and the size of the formwork meets the construction requirements.

[0044] C Check the center line of the road, and use the total station to measure and set the concrete side form control piles at the road base. The pile distance of the straight section is not greater than 10m, and the curve section is not greater than 5m.

[0045] D Use a level to measure the elevation of the road base concrete side form control pile, and calculate the top surface elevation of the road base concrete side form at each control pile according to the design elevation.

[0046] ② Template installation

[0047] Bamboo plywood or steel formwork is used for the concrete side formwork of the road base. The size of the formwork assembly is strictly in accordance with the requirements, and the stakeout control is carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com