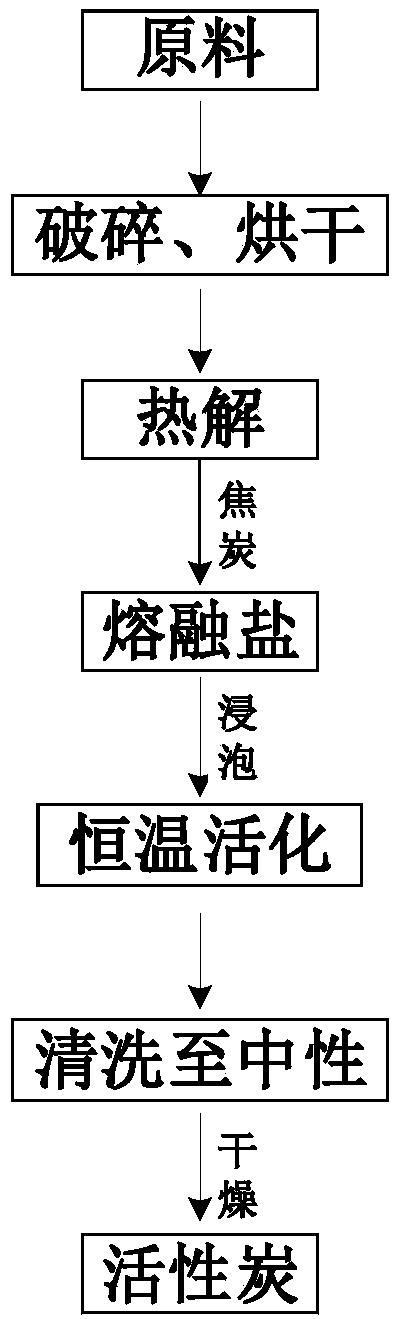

Method utilizing melt salt activation to prepare active carbon

A technology for preparing activated carbon and molten salt, applied in the field of activated carbon preparation, can solve the problems of waste, prolonged activated carbon cycle, aggravated pollution, etc., and achieve the effects of improving production efficiency, reducing production cost, and reducing salt waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Use industrial waste furfural slag as raw material: select 100g of furfural slag and crush it to 1mmg, dry it at 120°C until the quality is constant, put it in a heating furnace and pyrolyze it at a constant temperature of 400°C for 25min, put the coke produced by pyrolysis into the In molten salt at 400°C, take it out after constant temperature reaction for 2 minutes, and heat to 800°C under inert atmosphere for constant temperature activation at 600°C. Cool to room temperature, soak the obtained substance with 0.1mol / L hydrochloric acid solution, wash with water until neutral, and dry the obtained substance to be activated carbon.

Embodiment 2

[0023] Use agricultural waste corncobs as raw materials: choose 100g of corncobs and crush them to 1mm, dry them at 120°C until the quality is constant, put them in a heating furnace and pyrolyze them at a constant temperature of 350°C for 25min, put the coke produced by pyrolysis into the In molten salt at 400°C, take it out after constant temperature reaction for 2 minutes, and heat to 700°C under an inert atmosphere for constant temperature activation for 60 minutes. Cool to room temperature, soak the obtained substance with 0.1mol / L hydrochloric acid solution, wash with water until neutral, and dry the obtained substance to be activated carbon.

Embodiment 3

[0025] Coal as raw material: choose coal 100g crushed to 2mm, dry at 120°C until the quality is constant, put it in a heating furnace and pyrolyze it at a constant temperature of 500°C for 25 minutes, put the coke produced by pyrolysis into molten salt at 400°C , take out after constant temperature reaction for 2min, and heat to 900°C under inert atmosphere for constant temperature activation for 60min. Cool to room temperature, soak the obtained substance with 0.1mol / L hydrochloric acid solution, wash with water until neutral, and dry the obtained substance to be activated carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com