Circulating reuse method of pickling depleted brine and apparatus thereof

A waste brine and pickling technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as the need for improvement in the process, easy secondary damping, environmental pollution, etc. Achieve obvious economic and social benefits, solve difficult drying, and reduce the cost of salt production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

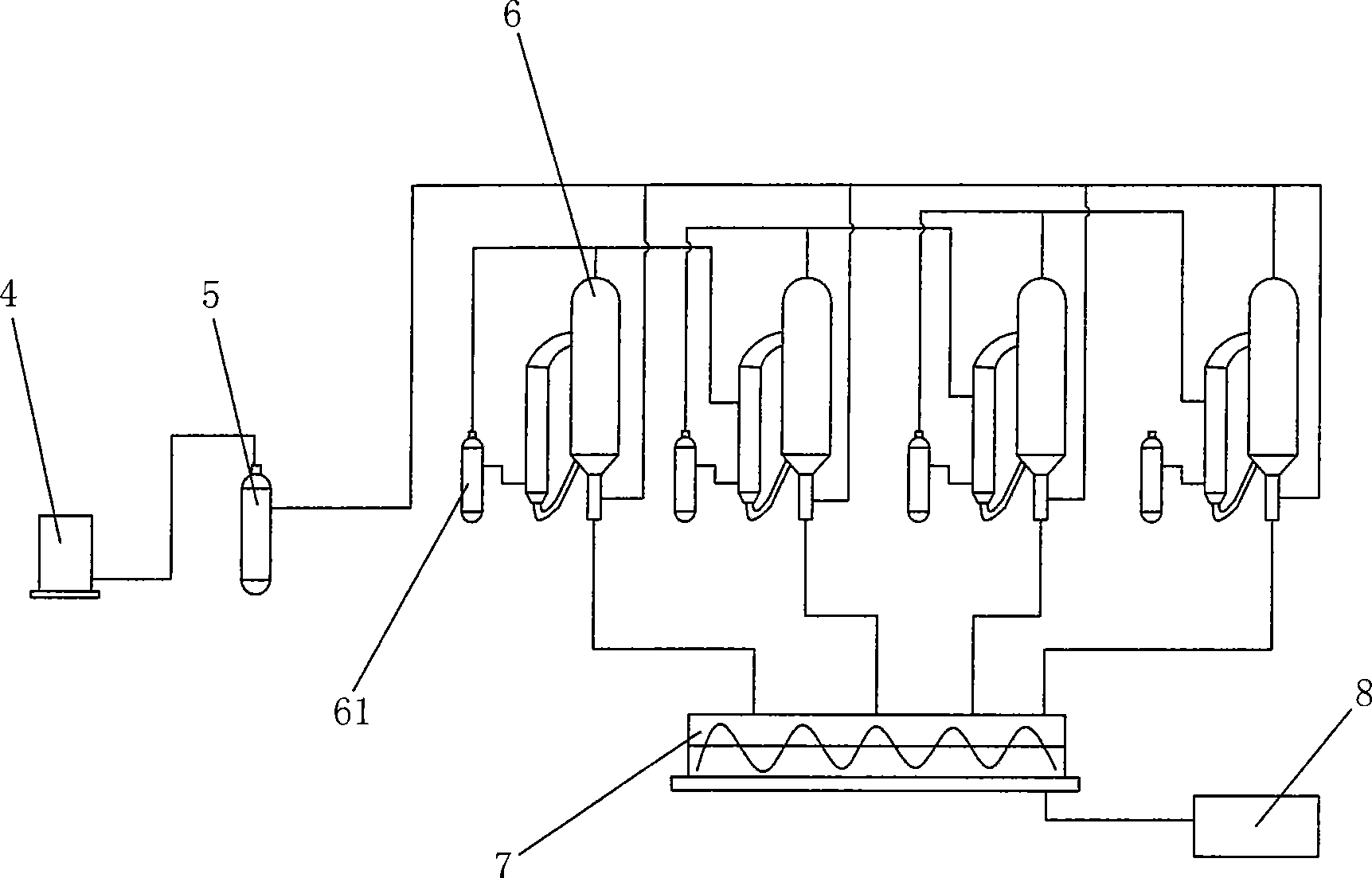

[0017] The specific method for recycling and reuse of pickled salt wastewater of the present invention comprises the following steps:

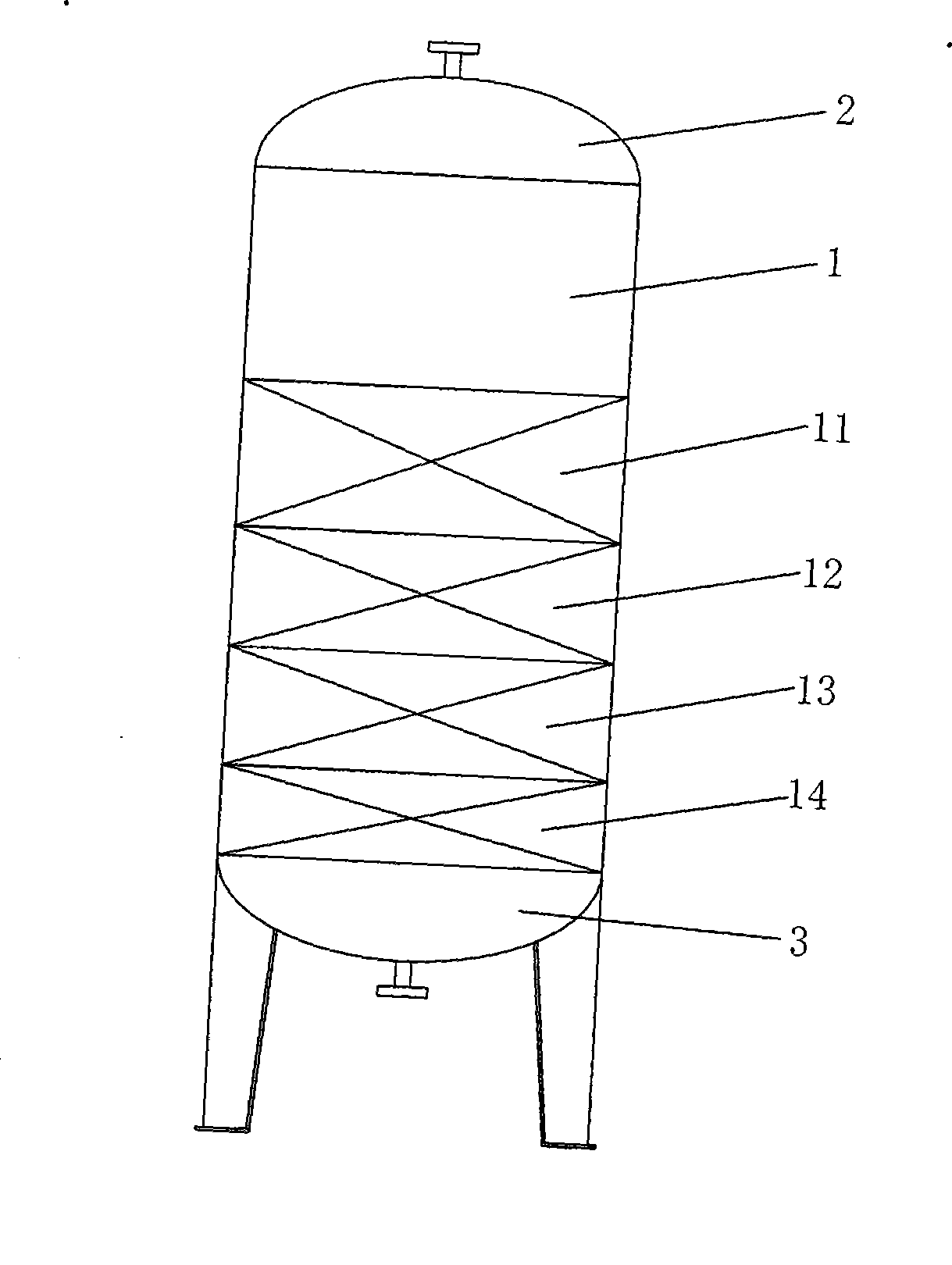

[0018] a) Physical slag removal process, in view of the characteristics of many mechanical impurities and harmful substances in pickled waste brine, quartz sand + activated carbon multi-layer composite filtration technology and device are used. An upper cover 2 and a lower cover 3 are respectively provided, and an activated carbon filling layer 11 , a fine quartz sand filling layer 12 , a medium and fine quartz sand filling layer 13 and a fine quartz sand filling layer 14 are arranged in the cylinder body 1 from top to bottom. Compared with the existing pretreatment technologies and devices such as ultrafiltration, the filter device of the present invention has the advantages of compact equipment, low energy consumption, long life, low cost, and easy operation and control, and can greatly reduce mechanical impurities and mechanical impurities i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com