Treatment system for solid salt waste in triglycidyl isocyanurate production

A technology of glycidyl ester and isocyanuric acid tri, which is applied in the field of salt solid waste treatment system, can solve the problems of decreased salt production rate, difficult industrial application, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

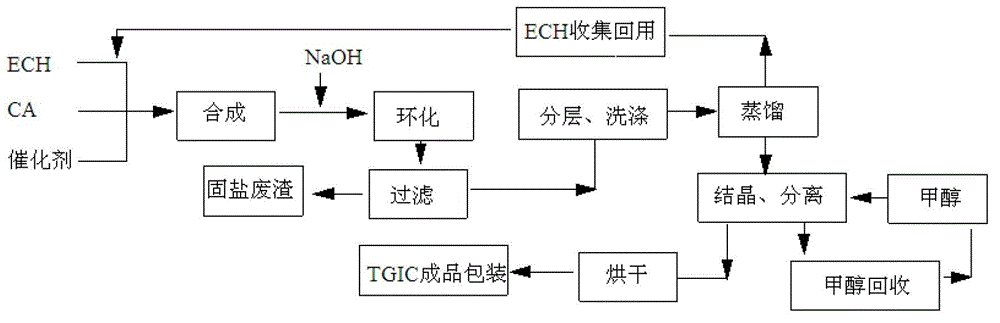

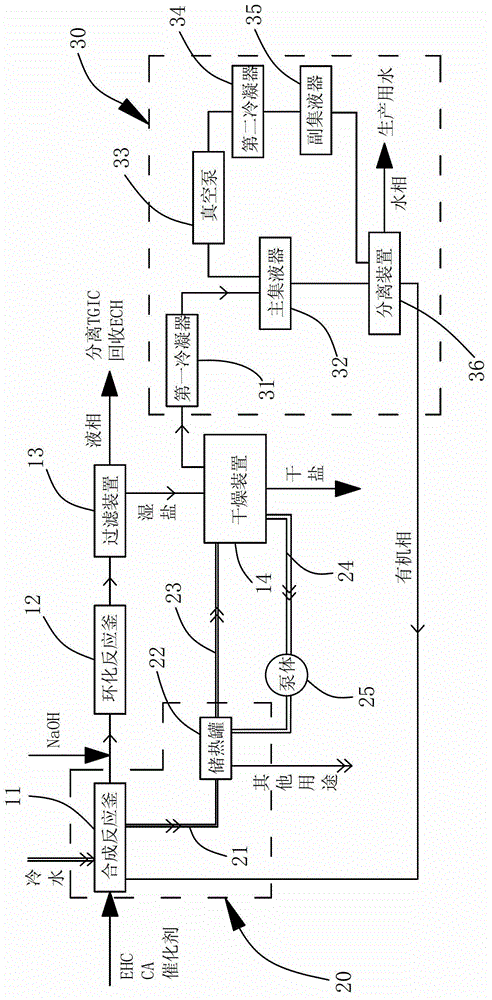

[0010] The purpose of this application is to provide a treatment system for solid salt waste in the production of triglycidyl isocyanurate. So far, the solid salt waste in TGIC production has not been effectively treated. The main reasons are as follows: First, the number and quantity of organic species contained in the solid salt waste produced in each batch of TGIC production process vary greatly. Salt waste is not a mixture of stable composition, so it cannot be directly used as a product or raw material; secondly, in the prior art, there is no effective separation and recovery of solid salt waste and effective utilization of the recovered components. Therefore, most of them are treated by incineration or calcination. The scheme adopted in this application, such as figure 2 Shown, a kind of processing system that is used for the solid waste in the production of triglycidyl isocyanurate, comprises the filter device 13 that is used to filter the mixture after the reaction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com