Wastewater treatment method

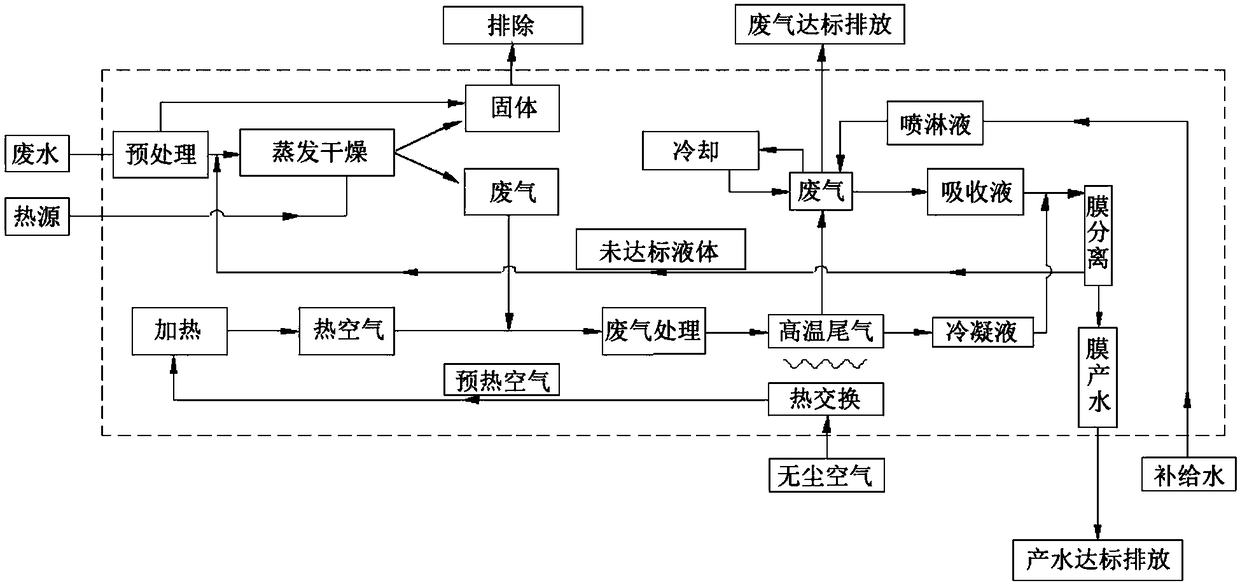

A waste water treatment, waste water technology, applied in the direction of water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low separation speed and separation efficiency, inability to degrade organic matter, waste of resources, etc. , to achieve the effect of fast separation speed, efficient desalination and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The COD of waste water in the hazardous waste treatment center is 100,000 mg / L, and the salt content is 100,000 mg / L. In addition, it contains a large amount of heavy metals such as arsenic, chromium, and nickel. The wastewater from the waste treatment center is introduced into the pretreatment tank at a flow rate of 3.6T / h, the pH is adjusted to 3.5-4.5 by adding sulfuric acid, and ferrous sulfate and hydrogen peroxide are added to carry out Fenton’s advanced oxidation. The dosage is 30kg / ton and 25L / t, after a residence time of 1.5 hours, add sodium hydroxide to adjust the pH to 10, and then add polyferric sulfate and PAM (polyacrylamide) for flocculation and precipitation. The liquid obtained in this process contains 60,000mg / L of COD, and the sludge output is 200kg / h. Solids such as sludge are solidified and landfilled by pressure filtration, and the liquid after separating the solids enters the evaporative drying system. Evaporated solid output is 600kg / h, and ste...

Embodiment 2

[0065]The COD of wastewater in the hazardous waste treatment center is 67000mg / L, and the salt content is 250000mg / L. In addition, it contains a large amount of compounds such as nitrogen and phosphorus, as well as heavy metals such as arsenic, chromium and nickel. The waste water from the waste treatment center is introduced into the pretreatment tank at a flow rate of 4.5T / h. After adding COD removal agent (5kg / ton of water) and diatomaceous earth (1kg / ton of water), after stirring for 10 minutes, it enters the plate and frame filter press Machine solid-liquid separation, waste water COD did not decrease significantly, but the chromaticity decreased by 50%. The solid output is 53kg / h, which is directly landfilled. The liquid after filtering out the solid enters the evaporative drying system, and the evaporated solid output is 1410kg / h, and the steam production is 3.1T / h. The COD content in the waste gas (water vapor doped with other harmful substances) condensate is 4000mg / L...

Embodiment 3

[0067] The landfill leachate concentrate has a COD of 25,000mg / L and a salt content of 75,000mg / L. Due to the small amount of water, the waste water is treated in the way of accumulative storage and intermittent treatment, and the treatment capacity per hour is 2T / h when driving. After the concentrated liquid in the regulating tank undergoes flocculation and sedimentation, the concentrated sludge enters the evaporative drying equipment after plate and frame pressure filtration. The solid output is 10kg / h, and the liquid after filtering the solid enters the evaporative drying system. Evaporated solid output is 185kg / h, and steam production is 1.8T / h. The COD content in the exhaust gas (water vapor doped with other harmful substances) condensate is 1000mg / L, and the salt content is 1500mg / L. The exhaust gas directly enters the RTO system for incineration, and the combustion temperature is 700-800°C. The nitrogen oxides in the high-temperature tail gas enter the membrane separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com