Garbage-percolate evaporating and concentrating processing method capable of recycling ammonia and device thereof

A technology for landfill leachate and evaporation concentration, which is applied in the field of evaporation and concentration treatment methods and equipment for landfill leachate or high-concentration wastewater, can solve the problems of complex treatment process, high cost, long treatment process, etc. The effect of low equipment cost and reduced operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

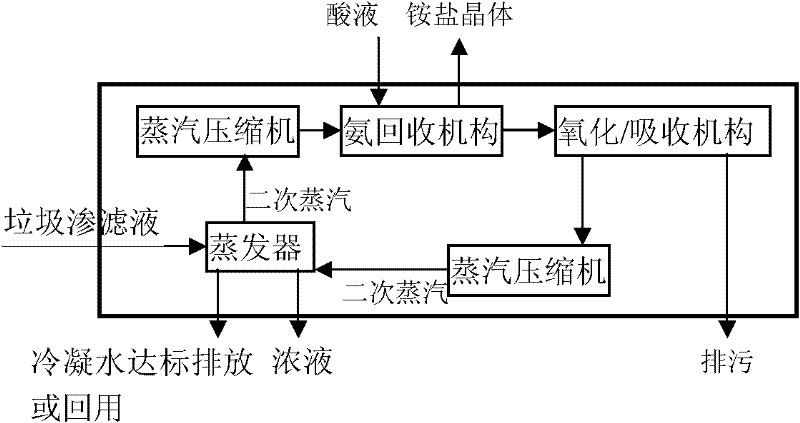

[0053] image 3 The shown landfill leachate evaporation and concentration equipment capable of ammonia recovery is one of the embodiments of the present invention, which includes units such as an evaporator, a steam compressor, an ammonia recovery mechanism, and an oxidation / absorption mechanism; the equipment of this embodiment Among them, the evaporator adopts the MVC horizontal evaporator, and the existing general vertical evaporator can also be used. The horizontal evaporator includes an evaporation chamber and a heating pipe, and an ammonia recovery mechanism is arranged on the pipeline between the steam outlet of the evaporation chamber and the heating pipe; the steam outlet communicates with the steam inlet of the ammonia recovery mechanism through the first pipeline, so that the The secondary steam evaporated from the evaporation chamber is sent to the ammonia recovery mechanism; the steam outlet of the ammonia recovery mechanism is connected with the steam inlet of th...

specific Embodiment 2

[0069] The difference between the landfill leachate treatment equipment of this embodiment and the specific embodiment 1 is that the oxidation / absorption mechanism and the second steam compressor are omitted, and its structural diagram is as follows Figure 4 shown. Its specific processing flow is:

[0070] (1) Firstly, the pretreated leachate is sent into the evaporator, and the ammonia and volatile substances produced by evaporation are discharged out of the evaporator along with the secondary steam;

[0071] (2) The secondary steam enters the steam compressor to pressurize and then enters the ammonia recovery mechanism.

[0072] (3) After the ammonia in the secondary steam is neutralized with the acid absorption liquid in the ammonia recovery mechanism, ammonium salts are precipitated, and the pH of the acid absorption liquid is kept at less than 4.5, while the temperature of the acid absorption liquid is controlled to be higher than that of the secondary steam 0- 5°C, so...

specific Embodiment 3

[0074] The difference between the landfill leachate treatment equipment of this embodiment and the specific embodiment 1 is that the first steam compressor and the oxidation / absorption mechanism are omitted, and its structural diagram is as follows Figure 5 shown. The specific processing flow is:

[0075] (1) Firstly, the pretreated leachate is sent into the evaporator, and the ammonia and volatile substances produced by evaporation are discharged out of the evaporator along with the secondary steam;

[0076] (2) The ammonia in the secondary steam is neutralized with the acid absorption liquid in the ammonia recovery mechanism, and ammonium salts are precipitated. The pH of the acid absorption liquid is kept at less than 4.5, and the temperature of the acid absorption liquid is controlled to be 0-5 higher than that of the secondary steam. ℃, so as to ensure that the steam does not participate in the reaction and remains unchanged. The neutralization reaction method requires ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com