Vertical shrimp culture system and culture method

The technology of a breeding system and a breeding method, applied in the field of aquaculture, can solve problems such as the inability to recycle the breeding pond, the low utilization rate of the breeding pond, and long-term vacancy, so as to reduce the amount of waste water output, shorten the output time, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

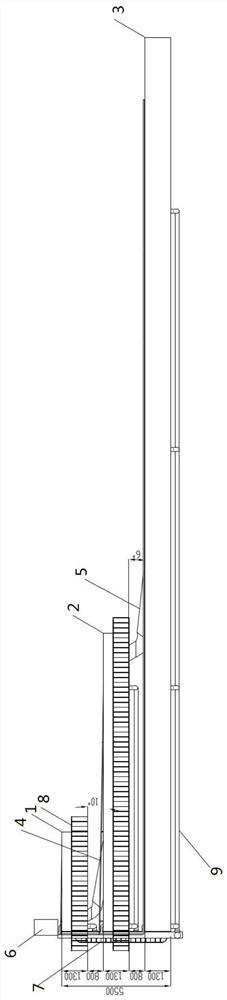

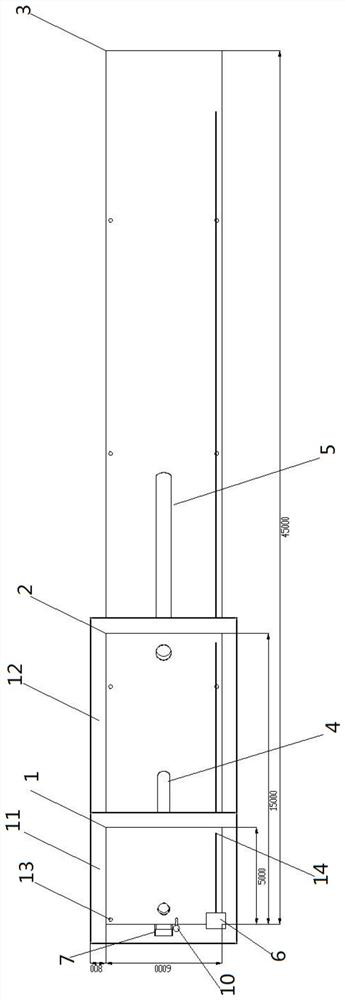

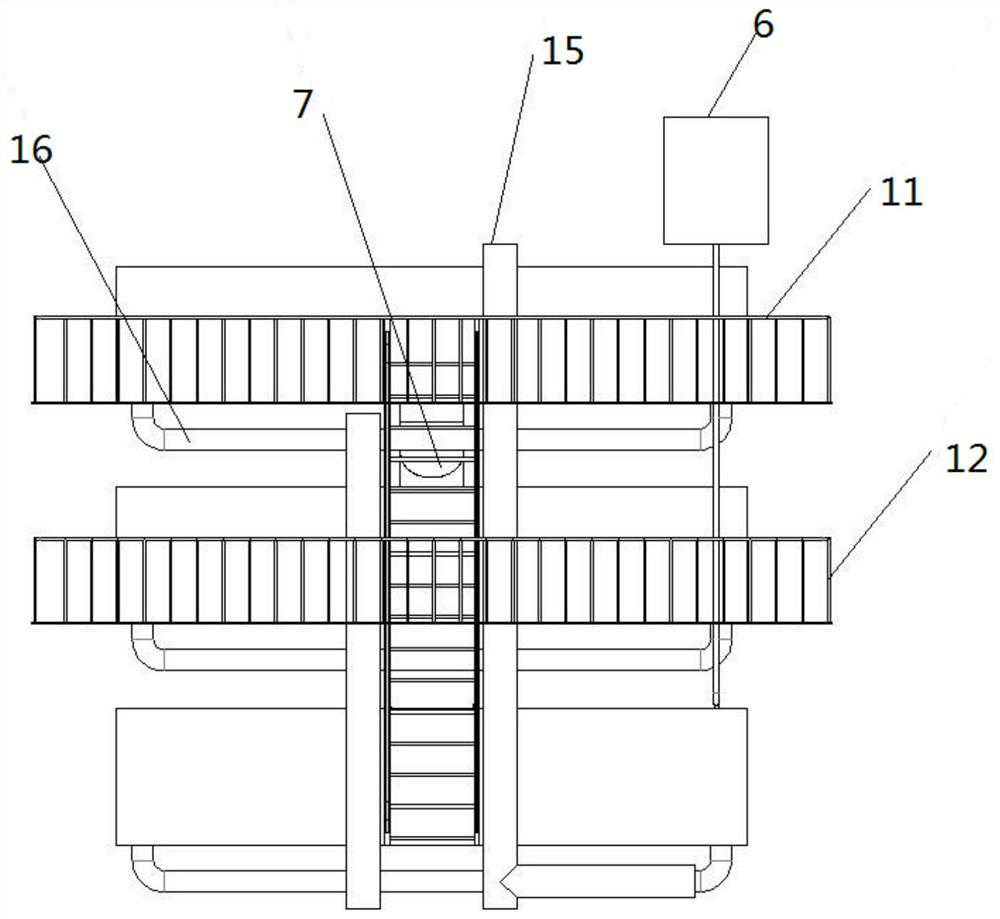

[0038] A vertical shrimp culture system, including a culture pond body, the culture pond body from top to bottom is a first-level culture pond 1, a second-level culture pond 2 and a third-level culture pond 3, and a ladder 7 is installed on the side wall of the culture pond body The width and height of all levels of culture ponds are all the same, being 1.3m and 0.6m respectively, the interval between adjacent culture ponds is 0.8m, and the lengths of all levels of culture ponds are respectively 5m, 15m and 45m; the culture pond body side walls are provided with Water supply main pipe 15, the water supply branch pipe 10 that is connected with the water supply main pipe 15 is arranged on the top of the culture ponds at all levels, and the water supply branch pipe 10 is correspondingly provided with the water valve that is used to control the water quantity; The bottom is provided with the drainage branch pipe 16 that communicates with the drainage main pipe 9, and the water valv...

Embodiment 2

[0040] Utilize above-mentioned shrimp culture system to carry out shrimp culture, comprise the following steps:

[0041] (1) In the primary culture pond 1, feed water for cultivation, keep the liquid level height as 1m, and put in shrimp seedlings, and the amount of throwing in shrimp seedlings is 600 / m 3 ;

[0042] (2) Add compound bacterial agent 10kg / time in the first-level breeding pond 1 at intervals of 3 days, put in 5-8% bait of 2 times of shrimp gross weight every day, until breeding for 25 days, the shrimp seedlings are passed through the first transfer Passage 4 is transferred in the secondary culture pond 2, according to the method for step (1), drops into new shrimp fry; The active ingredient of compound bacterial agent is Bifidobacterium bifidus, Bacillus thuringiensis, mesophilic thermoactinomycetes, pseudomonas Bacteria, Bifidobacterium bifidus, Bacillus thuringiensis, Mesophilic actinomycetes, and Pseudomonas have a ratio of 1:0.7:1.2:0.9;

[0043](3) In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com