Technology for treating stainless steel nitrate-free pickling waste water

A technology for wastewater treatment and pickling wastewater, which is applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve problems such as complex sludge composition, unsmooth operation, and high proportion of calcium sulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

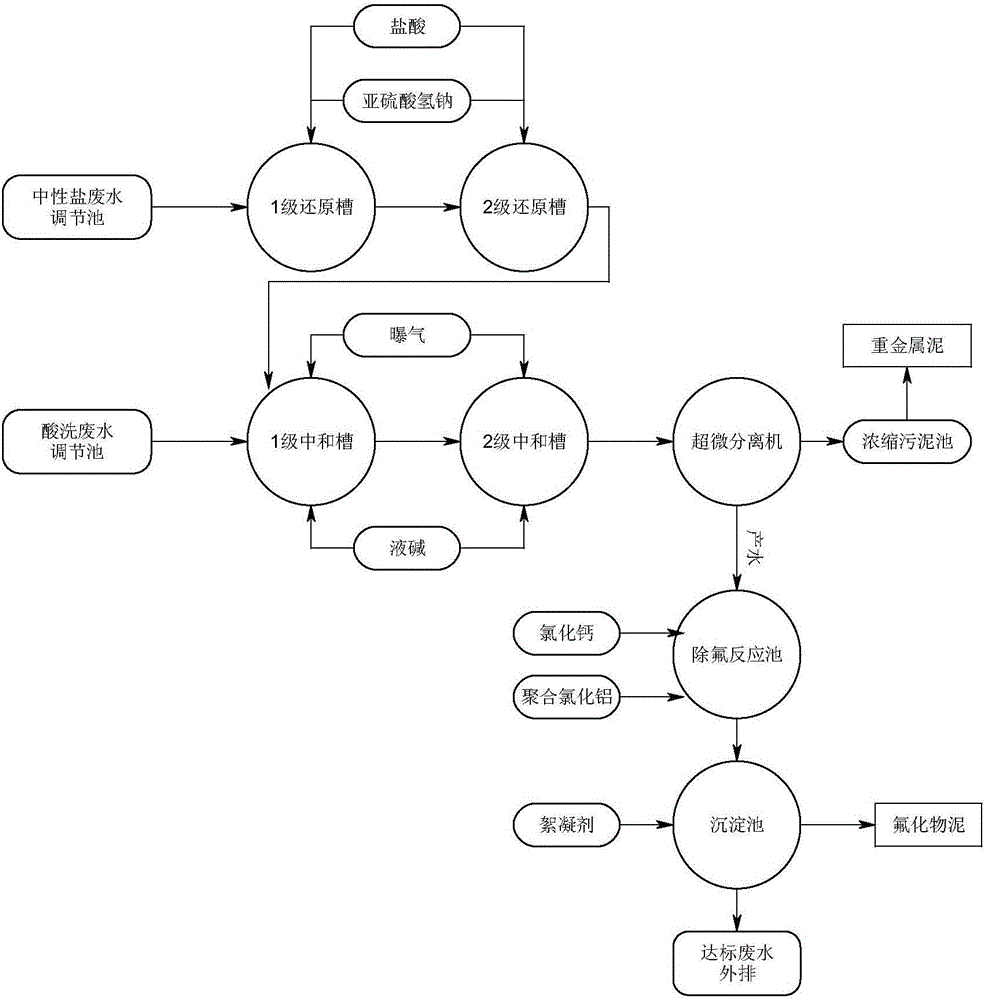

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] Such as figure 1 As shown, adopt the stainless steel nitric acid-free pickling wastewater treatment process in the present invention to process the neutral salt wastewater and pickling wastewater discharged from the cold rolling section of a steel factory, wherein the chromium ion concentration in this neutral salt wastewater is measured to be 73mg / L. The sulfuric acid concentration is 11g / L, the total iron in the pickling wastewater is 1728mg / L, the chromium ion concentration is 639mg / L, and the nickel ion concentration is 254mg.

[0019] (1) Firstly, the pickling wastewater and the neutral salt wastewater are introduced into the pickling wastewater adjustment tank and the neutral salt wastewater adjustment tank respectively.

[0020] (2) The neutral salt wastewater is introduced into the reduction tank from the neutral salt wastewat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com