Schiff base modified graphene oxide cement-based permeable crystallization type waterproof material as well as preparation and application thereof

A technology of permeable crystallization and waterproof materials, which is applied in the preparation of imino compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high production costs, low economic benefits, complex waterproofing agent formulations, etc., and achieve simple construction, Low environmental requirements and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

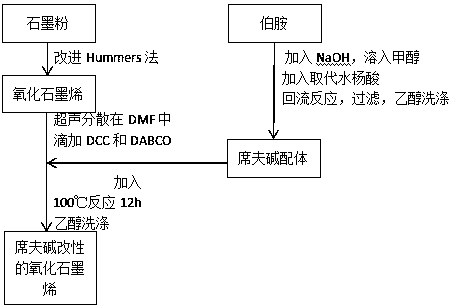

[0025] The preparation of embodiment 1 Schiff base modified graphene oxide

[0026] Follow the steps below:

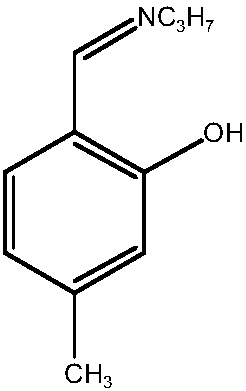

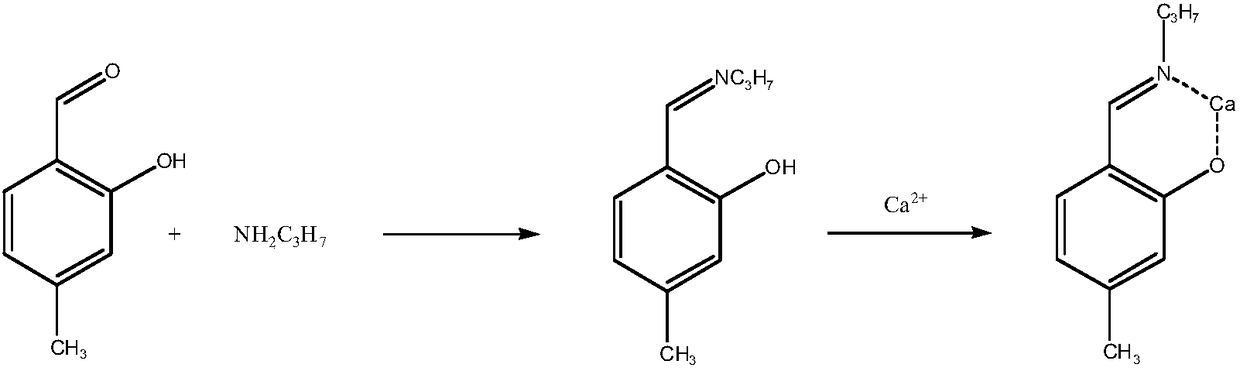

[0027] (1) Synthesis of Schiff base ligand: Dissolve 1 mol of propylamine and 0.1 mol of sodium hydroxide in methanol, add 1 mol of 4-methyl-substituted salicylaldehyde, heat and reflux for 5 hours to produce a solid, continue to reflux for 2 hours and then cool to room temperature, filtered, and the solid was repeatedly washed with ethanol to obtain the Schiff base ligand with a yield of 65%. The structural formula is:

[0028]

[0029] (2) Preparation of Schiff base-modified graphene oxide: Graphene oxide was prepared by the improved Hummers method, 1mol graphene oxide was uniformly dispersed in 50mL DMF by ultrasonic, stirred, and 10mL of 0.1mol DCC and 0.1mol DABCO were added dropwise DMF solution, continue to stir, add Schiff base ligand while stirring, react at 100°C for 12h, stop the reaction, filter, and wash the solid repeatedly with ethanol to obtain Schi...

Embodiment 2

[0032] The preparation of embodiment 2 Schiff base modified graphene oxide

[0033] Follow the steps below:

[0034] (1) Synthesis of Schiff base ligands: Dissolve 1mol butylamine and 0.2mol sodium hydroxide in methanol, add 1.2mol 4-fluorosalicylaldehyde, heat and reflux for 4 hours to produce solids, continue to reflux for 2 hours and then cool to At room temperature, filter, and wash the solid with ethanol repeatedly to obtain the Schiff base ligand with a yield of 93%. The structural formula is:

[0035]

[0036] (2) Preparation of Schiff base-modified graphene oxide: Graphene oxide was prepared by the improved Hummers method, 1.2mol graphene oxide was uniformly dispersed in 50mL DMF by ultrasonic, stirred, and 0.1mol DCC and 0.6mol DABCO were added dropwise 10mL DMF solution, continue to stir, add 1mol Schiff base ligand while stirring, react at 100°C for 12h, stop the reaction, filter, and wash the solid repeatedly with ethanol to obtain Schiff base modified graphene...

Embodiment 3-7

[0039] Example 3-7 Preparation of Schiff base modified graphene oxide cement-based permeable crystalline waterproof material

[0040]

[0041] Each component is weighed according to the proportion, placed in a gravity-free mortar mixer and stirred evenly to prepare a Schiff base modified graphene oxide cement-based permeable crystalline waterproof material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com