Method for synthesizing calcium epoxysuccinate suspension and method for producing l‑(+)‑tartaric acid

A technology of calcium epoxy succinate and epoxy succinic acid, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of low batch conversion efficiency, achieve significant industrial application value, and reduce raw materials cost, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

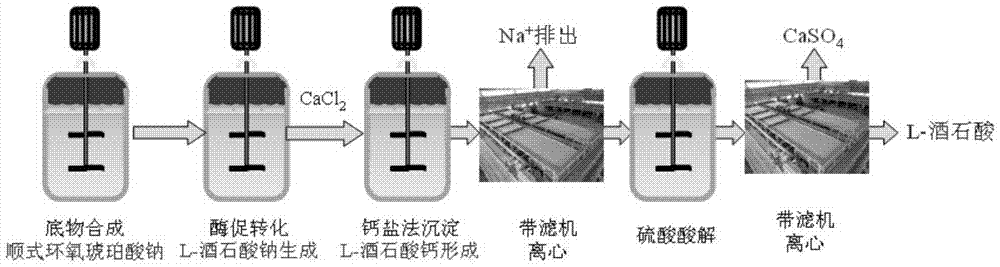

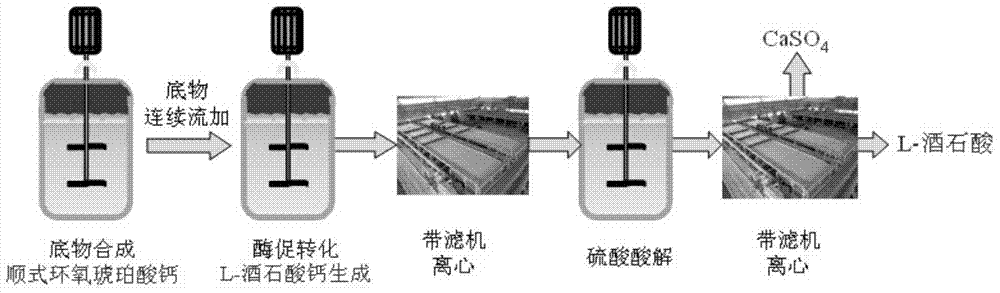

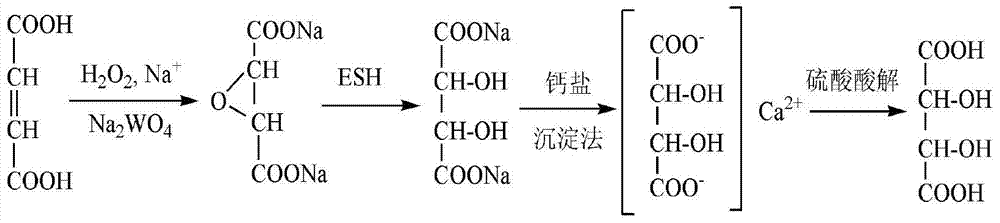

Method used

Image

Examples

Embodiment 1

[0042] Synthesis of cis-epoxysuccinate Calcium Suspension

[0043] Preheat 2.5L of pure water to 55°C, then add 0.8kg of maleic anhydride, stir with a mechanical stirrer, and slowly add 0.8kg of calcium carbonate, after it is fully mixed, add 2g of sodium tungstate, and feed at the same time Hydrogen peroxide (3L / h, a total of 1.5L, the content is 27.5%), then, the temperature is raised to between 65 ~ 69 ℃, and the heat preservation reaction is completed after about 4.5h, and about 4.5L of cis-epoxy calcium calcium suspension is obtained liquid.

[0044] Sodium sulfate co-solvent promotes continuous catalytic hydrolysis of calcium cis-epoxysuccinate

[0045] First, add 2L of 1.2M sodium sulfate co-solvent to the conversion reaction kettle, then add the cis-epoxy calcium calcium suspension prepared in the previous step to the reaction kettle with a continuous flow of 0.5L / h, and add A certain amount of Escherichia coli engineering bacteria producing cis-epoxysuccinate hydrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com