Agricultural weeding plunger type grass treating extruder

A plunger type and extruder technology, which is applied in the field of agricultural weeding machines, can solve the problems such as the inability of seeds to obtain nutrients, the inability of seeds to grow normally, and the low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

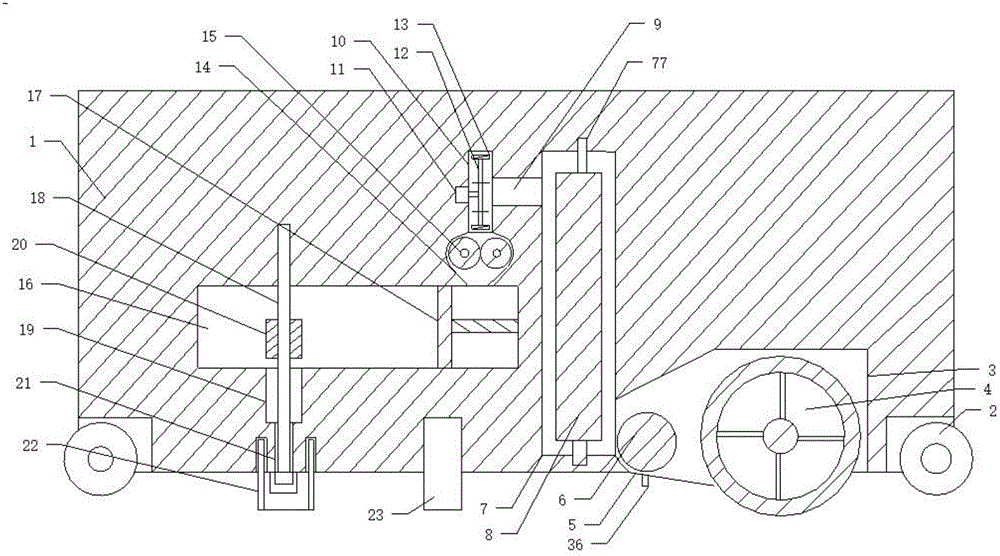

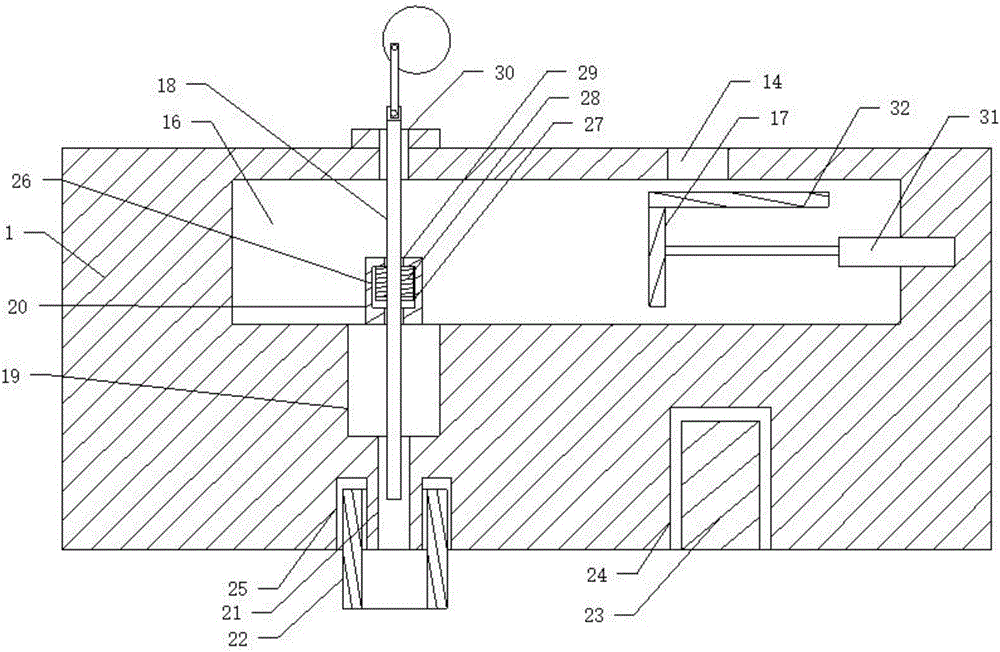

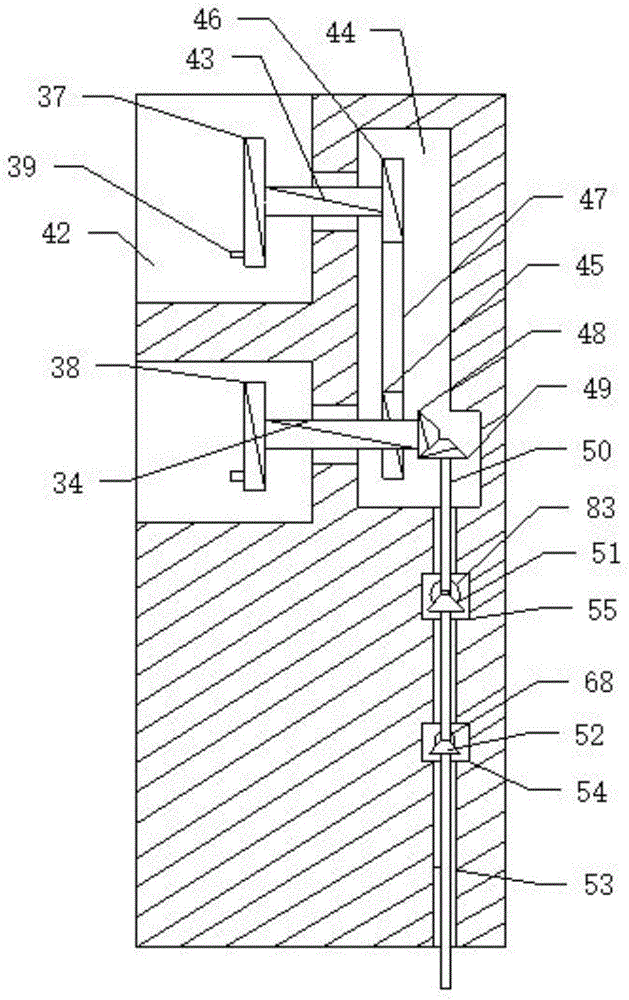

[0042] Such as Figure 1 to Figure 10 As shown, an agricultural weeding plunger type grass processing extruder includes a tractor, the tractor is provided with a power output shaft, and a body 1 is connected to the tractor, and the four corners of the body 1 are respectively provided with rotating rollers 2.

[0043] The bottom of the body 1 is provided with a weeding bottom groove 3, and a rotating weeding roller 4 is arranged in the weeding bottom groove 3, and a body 1 is connected on the tractor, so that the power output shaft on the tractor can be used to further output the rotating wheel. power, the bottom of the body 1 is provided with a weeding bottom groove 3, and a rotating weeding roller 4 is arranged in the described weeding bottom groove 3, so that the weeding roller 4 can be used to further control the weeding in the field during the rotation process. Grass to be cleared.

[0044] The weeding bottom trough 3 is also provided with a first conveying plate 6 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com