Hot isostatic pressing forming method of nickel-based high-temperature alloy powder disc

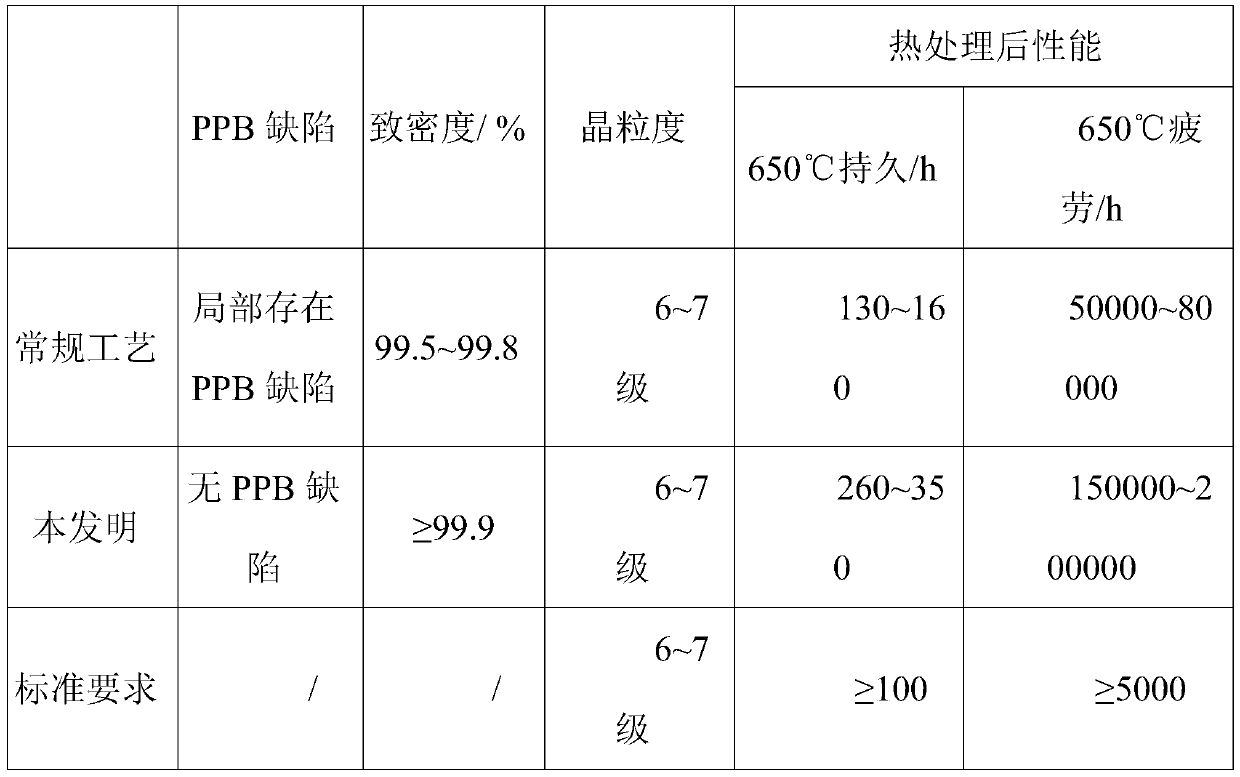

A nickel-based superalloy, hot isostatic pressing technology, applied in other manufacturing equipment/tools, engine components, turbines, etc., can solve problems such as original grain boundary defects, avoid abnormal grain growth, and improve alloy density , the effect of suppressing the formation of boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A hot isostatic pressing method for FGH4097 alloy powder, comprising the following steps:

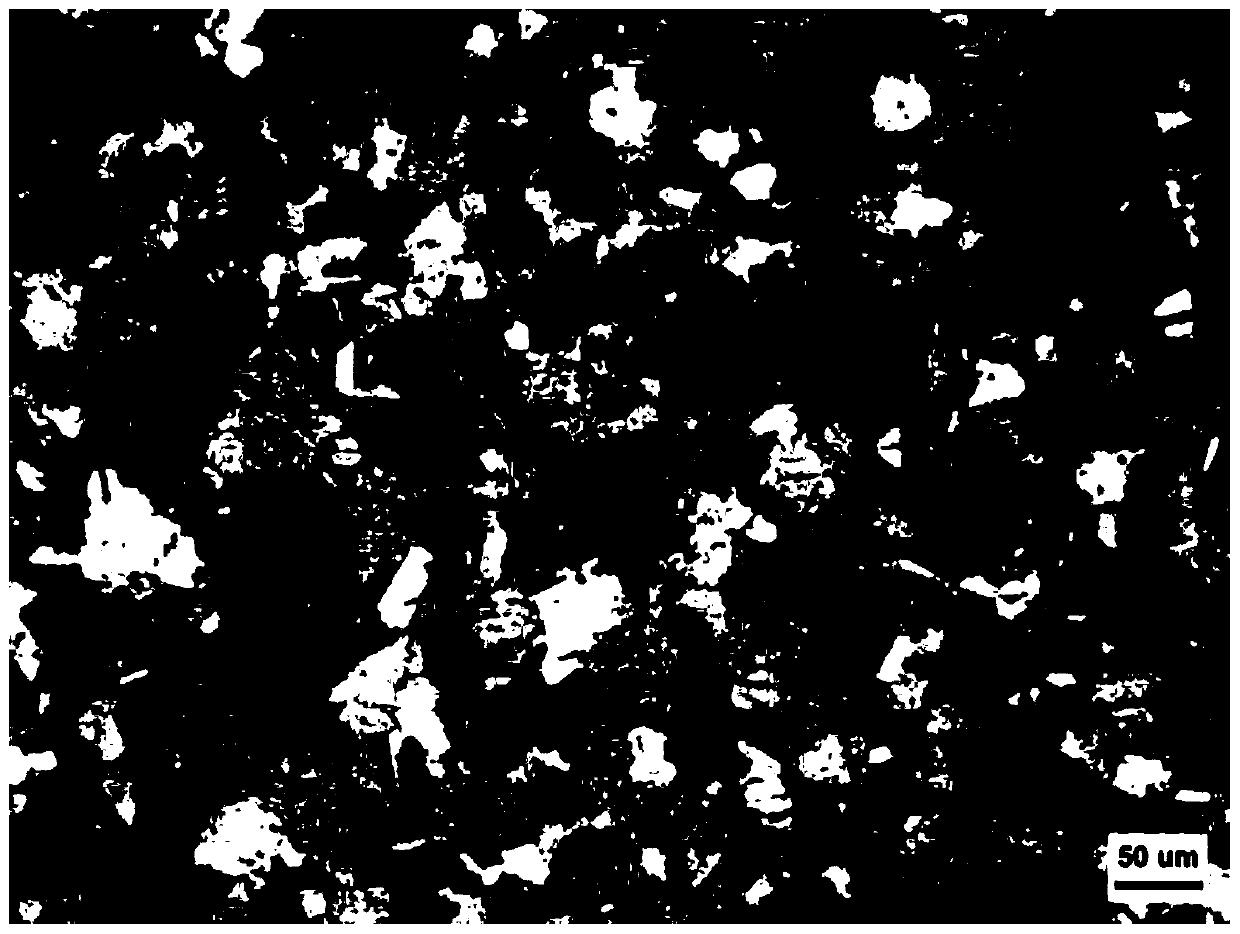

[0040] (1) Use the plasma rotating electrode method to prepare superalloy powder, sieve to 50-150 μm under the protection of argon, and electrostatically separate to remove non-metallic inclusions, then put the powder into a sheath and seal welding under vacuum. Abstract The attached picture shows the morphology of superalloy powder prepared by plasma rotating electrode.

[0041] (2) The package after sealing and welding is placed in the hot isostatic pressing equipment, and the hot isostatic pressing is carried out by simultaneously raising the temperature and increasing the pressure. The hot isostatic pressing temperature of the first step is 1200 ° C, the pressure is 100 MPa, and the heat preservation is 1 hour;

[0042] (3) After the first step is completed, the temperature is raised to 1300°C, and the pressure is 100MPa and kept for 30min;

[0043] (4) After the second step...

Embodiment 2

[0048] A hot isostatic pressing method for FGH4097 alloy powder, comprising the following steps:

[0049] (1) Use the plasma rotating electrode method to prepare superalloy powder, sieve to 50-150 μm under the protection of argon, and electrostatically separate to remove non-metallic inclusions, then put the powder into a sheath and seal welding under vacuum. Abstract The attached picture shows the morphology of superalloy powder prepared by plasma rotating electrode.

[0050] (2) The package after sealing and welding is placed in the hot isostatic pressing equipment, and the hot isostatic pressing is carried out by simultaneously raising the temperature and increasing the pressure. The hot isostatic pressing temperature of the first step is 1210 ° C, the pressure is 100 MPa, and the heat preservation is 1 hour;

[0051] (3) After the first step is completed, the temperature is raised to 1270°C, and the pressure is 100MPa and kept for 30min;

[0052] (4) After the second step i...

Embodiment 3

[0055] A hot isostatic pressing method for FGH4097 alloy powder, comprising the following steps:

[0056] (1) Use the plasma rotating electrode method to prepare superalloy powder, sieve to 50-150 μm under the protection of argon, and electrostatically separate to remove non-metallic inclusions, then put the powder into a sheath and seal welding under vacuum. Abstract The attached picture shows the morphology of superalloy powder prepared by plasma rotating electrode.

[0057] (2) The package after sealing and welding is placed in the hot isostatic pressing equipment, and the hot isostatic pressing is carried out by simultaneously raising the temperature and increasing the pressure. The hot isostatic pressing temperature of the first step is 1220 ° C, the pressure is 100 MPa, and the heat preservation is 1 hour;

[0058] (3) After the first step is completed, the temperature is raised to 1250 ° C, and the pressure is 100 MPa for 30 minutes;

[0059] (5) After the second step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com