Inner strip edge sealing process method of inner honeycomb plate

A process method and technology of honeycomb panels, applied in chemical instruments and methods, layered products, lamination auxiliary operations, etc., can solve the problem that the inner honeycomb panels are easily damaged and the aesthetics are easily damaged, and the wooden honeycomb panels are easily damaged and affect the inner honeycomb panels. Aesthetics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

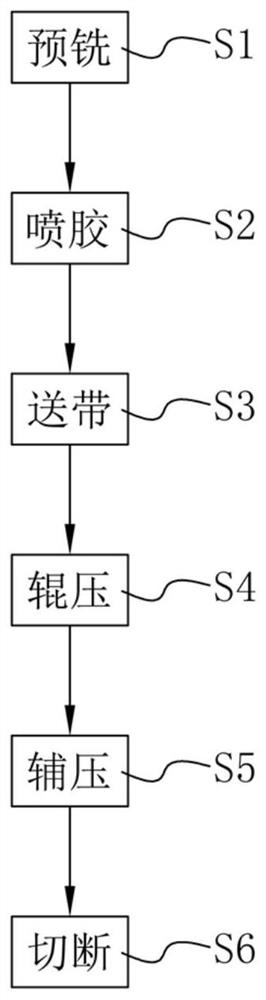

[0044] A kind of inner edge banding process method of inner honeycomb plate, such as Figure 1 to Figure 4 shown, including the following steps:

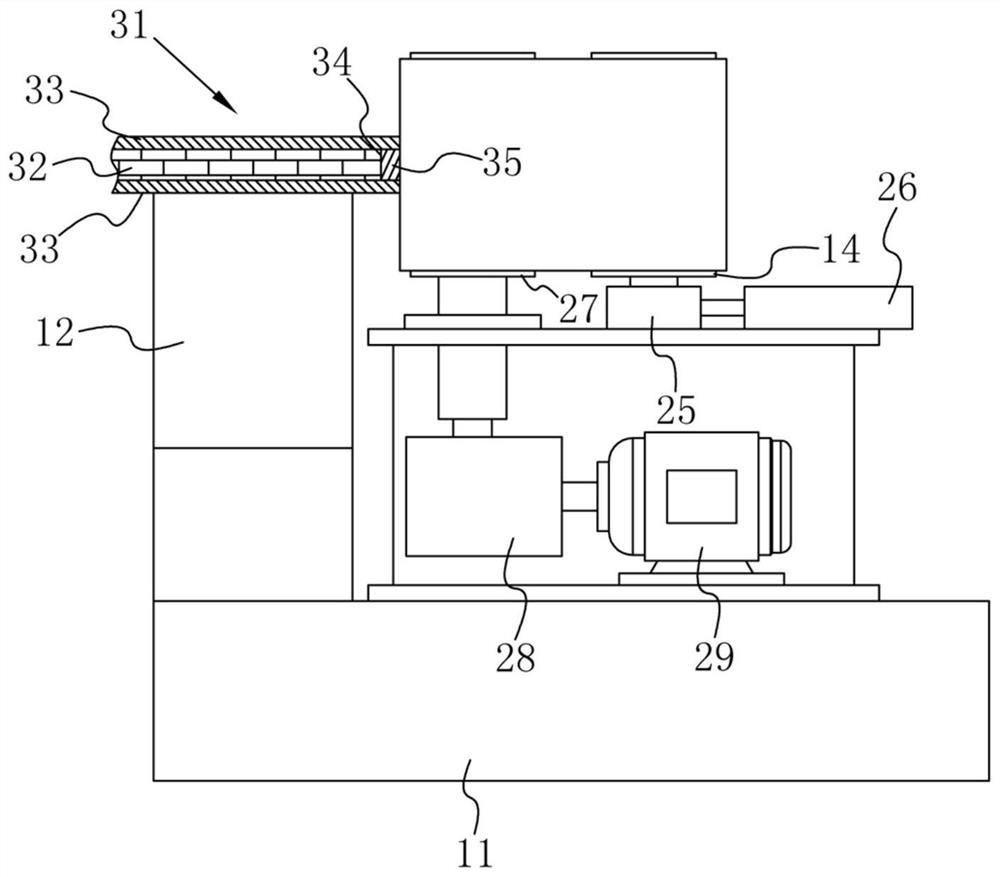

[0045] S1, pre-milling: milling the edge of the wooden honeycomb panel 32 to form an installation groove 34 surrounded by the wooden honeycomb panel 32 and two partitions 33; the cross section of the installation groove 34 is generally rectangular;

[0046] S2. Glue spraying: spray glue into the installation groove 34; spray glue at two right angles inside the installation groove 34;

[0047] S3, tape delivery: the seal 35 is delivered to the installation groove 34, the extension direction of the seal 35 is the same as the extension direction of the installation groove 34, the length of the seal 35 is greater than the length of the installation groove 34 and the two ends of the seal 35 are separated from the installation groove 34 respectively. protrude from both ends;

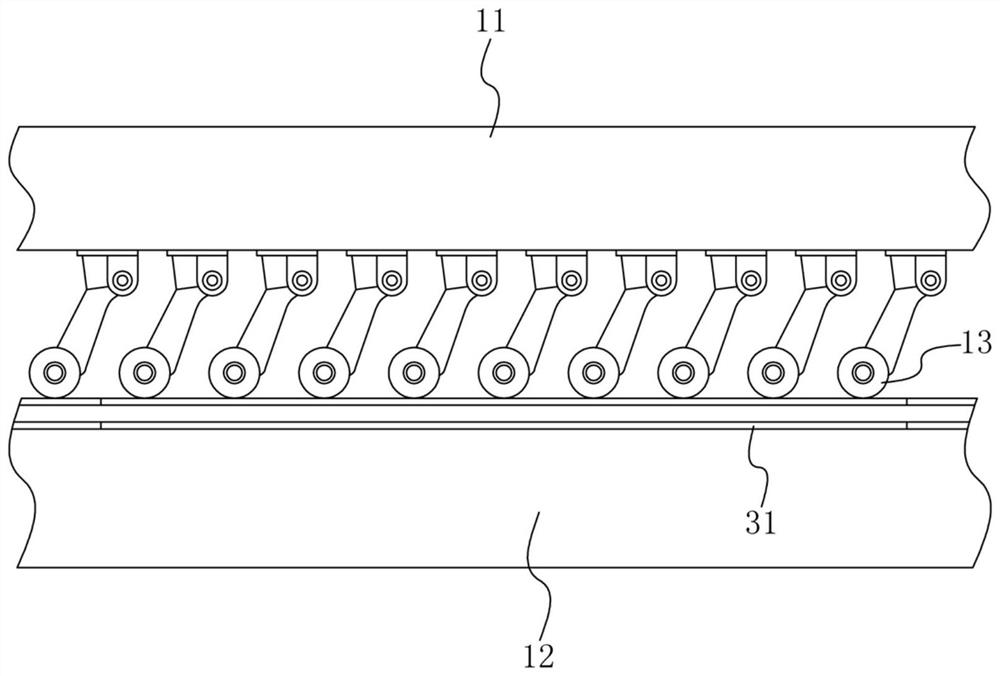

[0048] S4. Roll pressing: press the guide roller to the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com