Gold removing and tin coating method and lead tin coating protective agent for lead of connector between gold-plated plates, and preparation method of lead tin coating protective agent

An inter-board connector and protective agent technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of expensive equipment and materials, complicated removal process, etc., and achieve a reasonable and acceptable concentration of components. Control, preparation method is simple and easy, and the effect of good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

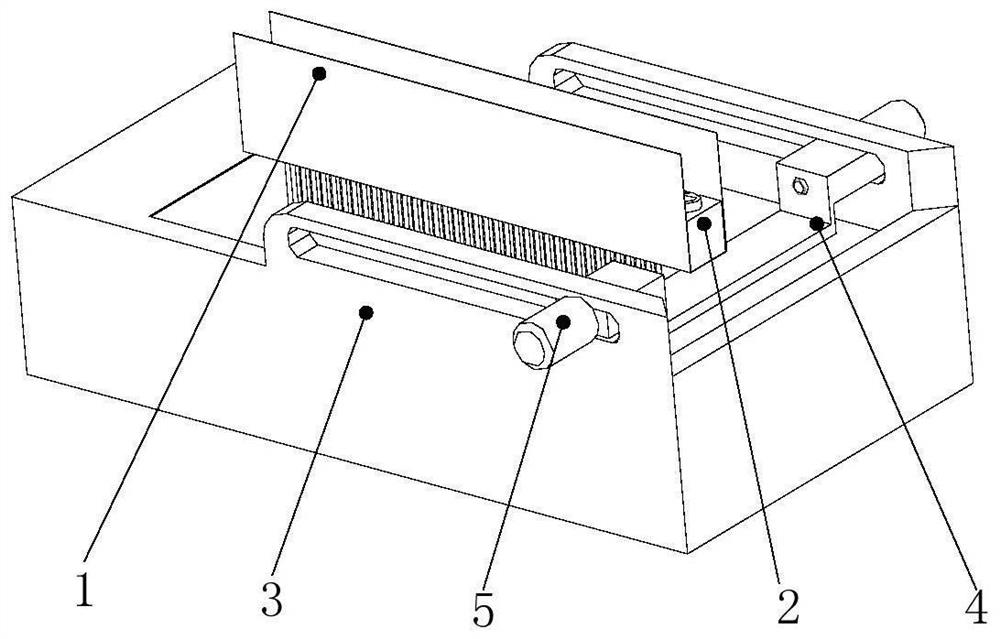

Image

Examples

Embodiment 1

[0038] A preparation method of a tin-coating protectant for connectors between gold-plated boards. Firstly, deionized water and acrylic acid emulsion are added into a reactor, and mixed evenly at a rotating speed of 400 rpm. Continue to stir, and add ammonium polyphosphate, pentaerythritol, melamine and titanium dioxide to the above slurry, and continue to stir for 10 minutes to make the slurry mix evenly. The mixed slurry is transferred to a grinder for grinding, and the slurry is ground to a fineness of 20 μm. Transfer the ground slurry to a mixer, stir at a rotational speed of 1500 rpm, add cellulose ether and high temperature resistant antioxidant, and continue stirring for 10 minutes to mix the slurry evenly to obtain a tin enamel protectant.

[0039] The mass concentration of each component in the tin enamel protectant in this embodiment is: 10% of acrylic emulsion, 25% of ammonium polyphosphate, 5% of pentaerythritol, 5% of melamine, 10% of titanium dioxide, 1% of cellu...

Embodiment 2

[0046] A preparation method of a tin-coating protectant for connectors between gold-plated boards. Firstly, deionized water and acrylic acid emulsion are added into a reactor, and mixed evenly at a rotating speed of 430 rpm. Continue to stir, and add ammonium polyphosphate, pentaerythritol, melamine and titanium dioxide to the above slurry, and continue to stir for 9 minutes to make the slurry mix evenly. The mixed slurry is transferred to a grinder for grinding, and the slurry is ground to a fineness of 35 μm. Transfer the ground slurry to a mixer, stir at a speed of 1600 rpm, add cellulose ether and high temperature resistant antioxidant, and continue stirring for 9 minutes to mix the slurry evenly to obtain a tin enamel protectant.

[0047] The mass concentration of each component in the tin enamel protectant in this embodiment is: 11.7% of acrylic emulsion, 25.3% of ammonium polyphosphate, 5.7% of pentaerythritol, 5.7% of melamine, 11.5% of titanium dioxide, 1.2% of cellul...

Embodiment 3

[0054] A preparation method of a tin-coating protectant for connectors between gold-plated boards. First, deionized water and acrylic acid emulsion are added into a reactor, and mixed evenly at a rotating speed of 460 rpm. Continue stirring, and add ammonium polyphosphate, pentaerythritol, melamine and titanium dioxide to the above slurry, and continue stirring for 8 minutes to make the slurry mix evenly. The mixed slurry is transferred to a grinder for grinding, and the slurry is ground to a fineness of 40 μm. Transfer the grinded slurry to a mixer, stir at a speed of 1700 rpm, add cellulose ether and high temperature resistant antioxidant, and continue stirring for 8 minutes to mix the slurry evenly to obtain a tin enamel protectant.

[0055] The mass concentration of each component in the tin enamel protectant in this embodiment is: 13% of acrylic emulsion, 26.4% of ammonium polyphosphate, 8% of pentaerythritol, 6.2% of melamine, 12.4% of titanium dioxide, 1.9% of cellulose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com