Railroad bed waterproof structure and pavement method thereof

A technology for waterproof structures and railway subgrades, which is applied in infrastructure engineering, roads, tracks, etc., and can solve problems such as being easily punctured by ballast, poor durability, and unable to improve the strength of the foundation bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

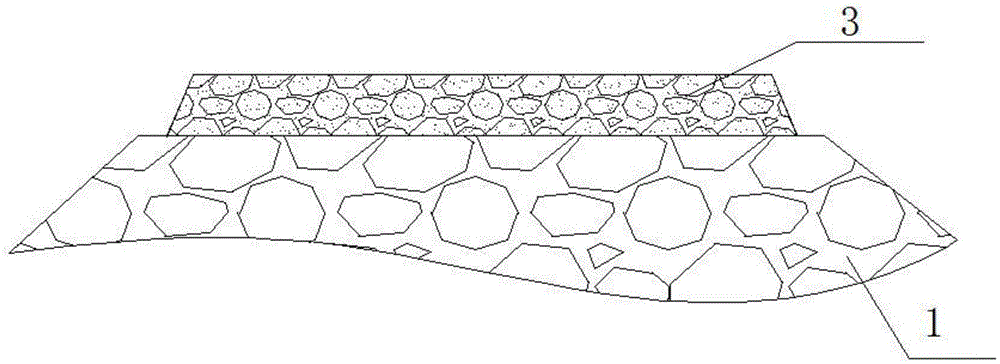

[0013] Such as figure 1 As shown, the waterproof structure of the railway subgrade is a waterproof layer 3 arranged between the surface of the railway subgrade 1 and the ballast, and the waterproof layer 3 is composed of crushed stones accumulated on the surface of the railway subgrade 1 and polymer waterproof paint filled in the gap between the crushed stones , the waterproof layer 3 has a double-sided drainage slope of 5%, the water that seeps down to the waterproof layer 3 is isolated by the waterproof layer 3, and then flows out of the waterproof layer 3 through the drainage slope.

[0014] The laying method of the waterproof structure is as follows: lay gravel with an average particle size of 6mm on the surface of the railway subgrade 1, the laying thickness is 5cm, the transverse width of the main line is 5m, and the distance from the bottom of the rail is 30cm; Spray the polyurethane waterproof coating into the gravel gap in the direction, and then spray the polyurethan...

Embodiment 2

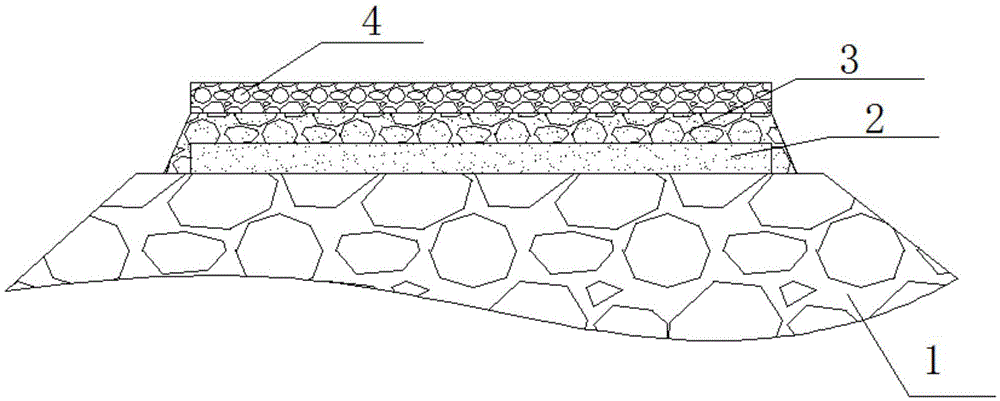

[0017] The laying method of the waterproof structure is as follows: Firstly, a uniform, dense and flat sand cushion layer 2 is laid, the average particle size of the sand material is 3 mm, and the laying thickness is 5 cm. Then the crushed stones with an average particle size of 6mm are laid on the above-mentioned sand cushion 2, the laying thickness is 5cm, the transverse width on the main line is 5m, and 30cm away from the bottom of the rail; Spray into the gravel gap, and then spray the polyurethane waterproof coating into the gravel gap along the direction parallel to the longitudinal direction of the line, so that the polyurethane waterproof coating fills all the gravel pores. After the polyurethane waterproof coating in the gravel gap is completely solidified, That is to obtain the waterproof layer 3; then paving the gravel layer 4 which protects the waterproof layer 3 on the surface of the waterproof layer 3, the average particle size of the gravel used is 8 mm, and the ...

Embodiment 3

[0019] The laying method of the waterproof structure is as follows: Firstly, a uniform, dense and flat sand cushion layer 2 is laid, the average particle size of the sand material is 3 mm, and the laying thickness is 5 cm. Then the crushed stones with an average particle size of 6mm are laid on the above-mentioned sand cushion 2, the laying thickness is 3cm, the transverse width on the main line is 6m, and 30cm away from the bottom of the rail; Spray into the gravel gap, and then spray the polyurethane waterproof coating into the gravel gap along the direction parallel to the longitudinal direction of the line, so that the polyurethane waterproof coating fills all the gravel pores. After the polyurethane waterproof coating in the gravel gap is completely solidified, That is to obtain the waterproof layer 3; then paving the gravel layer 4 which protects the waterproof layer 3 on the surface of the waterproof layer 3, the average particle size of the gravel used is 8 mm, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com