Multistage stretching technology for manufacture aramid fiber III

A technology for controlling stretching and process, applied in the field of chemical synthetic fibers, can solve the problems that the stretching process is not suitable for aramid III fibers, etc., and achieve the effects of easy and stable control, low industrial cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

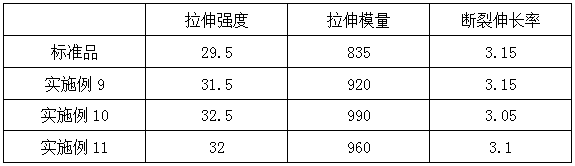

Examples

Embodiment 1

[0031] A multi-stage drawing process for manufacturing high-strength and high-modulus aramid fiber III, comprising the following process steps:

[0032] A, the spinning dope is extruded into a thin stream through the spinneret, and the thin stream is solidified in the first coagulation bath, and the stretching rate is controlled to -75% to carry out negative stretching treatment;

[0033] B, coagulated in the first coagulation bath and the fiber after the negative stretching treatment enters the second coagulation bath, and the stretching rate is controlled to 90% for plasticizing and stretching treatment;

[0034] C. The fibers coagulated and stretched in the second coagulation liquid enter the washing machine for washing;

[0035] D. Send the washed fiber into a wet heat stretching bath for plasticizing and stretching treatment again, and control the stretching rate to 1%, to obtain the product high-strength and high-modulus aramid III fiber.

Embodiment 2

[0037] A multi-stage drawing process for manufacturing high-strength and high-modulus aramid fiber III, comprising the following process steps:

[0038] A, the spinning dope is extruded into a thin stream through the spinneret, and the thin stream is solidified in the first coagulation bath, and the stretching rate is controlled to -30% for negative stretching treatment;

[0039] B, coagulated in the first coagulation bath and the fiber after negative stretching treatment enters the second coagulation bath, and the stretch rate is controlled to 150% for plasticizing and stretching treatment;

[0040] C. The fibers coagulated and stretched in the second coagulation liquid enter the washing machine for washing;

[0041] D. Put the washed fiber into the wet heat stretching bath for plasticizing and stretching treatment again, and control the stretching rate to 10%, to obtain the product high-strength and high-modulus aramid fiber III.

Embodiment 3

[0043] A multi-stage drawing process for manufacturing high-strength and high-modulus aramid fiber III, comprising the following process steps:

[0044] A, the spinning stock solution is extruded into a thin stream through the spinneret, and the thin stream is solidified in the first coagulation bath, and the stretching ratio is controlled to 52.5% to carry out negative stretching treatment;

[0045] B, coagulated in the first coagulation bath and the fiber after negative stretching treatment enters the second coagulation bath, and the stretching ratio is controlled to 120% for plasticizing and stretching treatment;

[0046] C. The fibers coagulated and stretched in the second coagulation liquid enter the washing machine for washing;

[0047] D. Send the washed fiber into a wet heat stretching bath for plasticizing and stretching again, and control the stretching rate to 5.5%, to obtain the product high-strength and high-modulus aramid III fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com