Sliding-resistant colored pavement surface and paving method thereof

A color, surface layer technology, applied to the coagulation pavement, roads, roads and other directions paved on site, can solve problems such as unfavorable traffic safety, poor wear resistance, complex process, etc., and achieve a high degree of mechanization and noise reduction. Improved, economical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

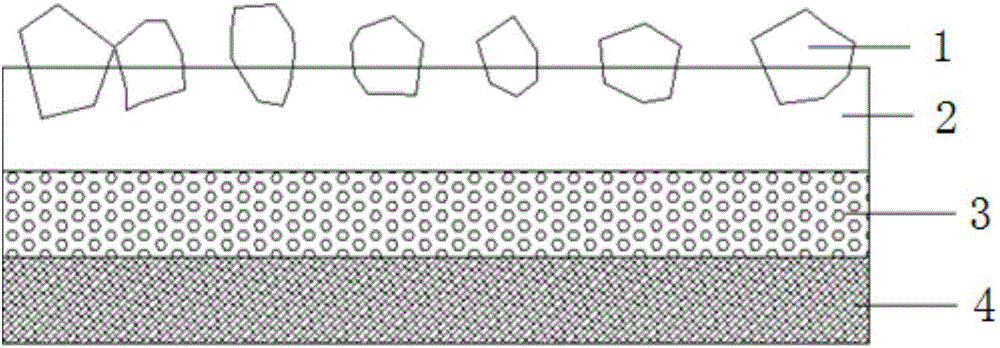

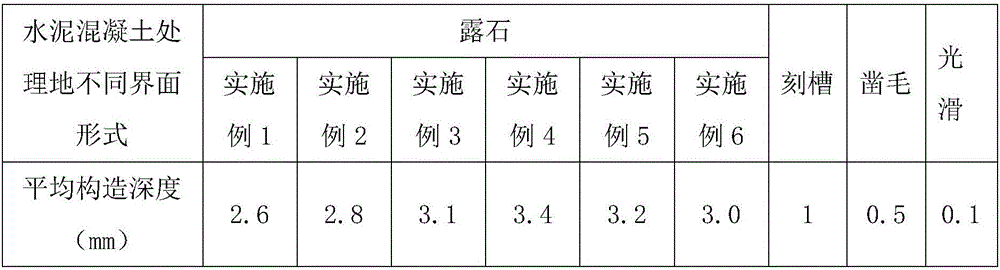

Embodiment 1

[0071] Firstly, the cement concrete with crushed stone gradation 5-10mm:10-20mm=1:6 is paved, vibrated and plastered on the base 3 of the pavement. When the surface temperature of cement concrete is 15°C, wait for After the water film on the surface of cement concrete disappears, apply 200g / m 2 After spraying the retarder at a certain dosage, immediately cover it with a plastic film for the first curing. Be careful not to have air bubbles. When the ambient temperature is 10°C, the curing time is 30 hours. Remove the plastic film and brush off the uncondensed mortar on the surface of the cement concrete, so that the surface of the cement concrete exposes evenly distributed crushed stones with a depth of 2.5 mm (measured by sand-laying method), and the degree of exposed stones is 40 pieces / m 2 , then carry out the second health care, then remove the dust and debris on the surface, apply a mixture of water-based epoxy resin binder and monochromatic color pigment (iron oxide red, ...

Embodiment 2

[0074] First of all, the cement concrete with crushed stone gradation 5-10mm:10-20mm=1:4 is paved, vibrated and plastered on the base of the pavement. When the surface temperature of the cement concrete is 30°C, the cement concrete table

[0075] After the surface water film disappears, apply 250g / m on its surface 2 After spraying the retarder at a certain dose, immediately cover it with a plastic film for the first curing. Be careful not to have air bubbles. When the ambient temperature is 20°C, the curing time is 20 hours. When the main cement concrete of the curing reaches a strength of 3.5MPa, Then uncover the plastic film, brush off the uncondensed mortar on the surface of the cement concrete, so that the surface of the cement concrete exposes evenly distributed crushed stones with a depth of 2.5 mm (measured by sand-laying method), and the exposed stone degree is 45 / m 2 , then carry out the second health care, then remove the dust and debris on the surface, apply a m...

Embodiment 3

[0078] First of all, cement concrete with crushed stone gradation 5-10mm:10-20mm=1:3 is paved, vibrated and plastered on the base course of the pavement. When the surface temperature of cement concrete is 45°C, the surface After the water film disappears, apply 300g / m on its surface 2 After spraying the retarder at a certain dose, immediately cover it with a plastic film for the first curing. Be careful not to have air bubbles. When the ambient temperature is 30°C, the curing time is 15 hours. When the main cement concrete of the curing reaches a strength of 2.5MPa , and then uncover the plastic film, brush off the uncondensed mortar on the surface of the cement concrete, so that the surface of the cement concrete exposes evenly distributed gravel with a depth of 2 mm (measured by sand-laying method), and the degree of exposed stone is 50 pieces / m 2 , then carry out the second health care, then remove the dust and debris on the surface, apply a mixture of water-based epoxy res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com