Satellite type superfine denier polyamide short fibre and producing method thereof

A production method and technology of polyamide, which can be used in fiber processing, filament/thread forming, conjugated synthetic polymer rayon, etc., and can solve problems such as unstable physical performance indicators, inability to form sea-island structures, and organic matter discharge environment. , to achieve the effect of easy dyeing, stable structure and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

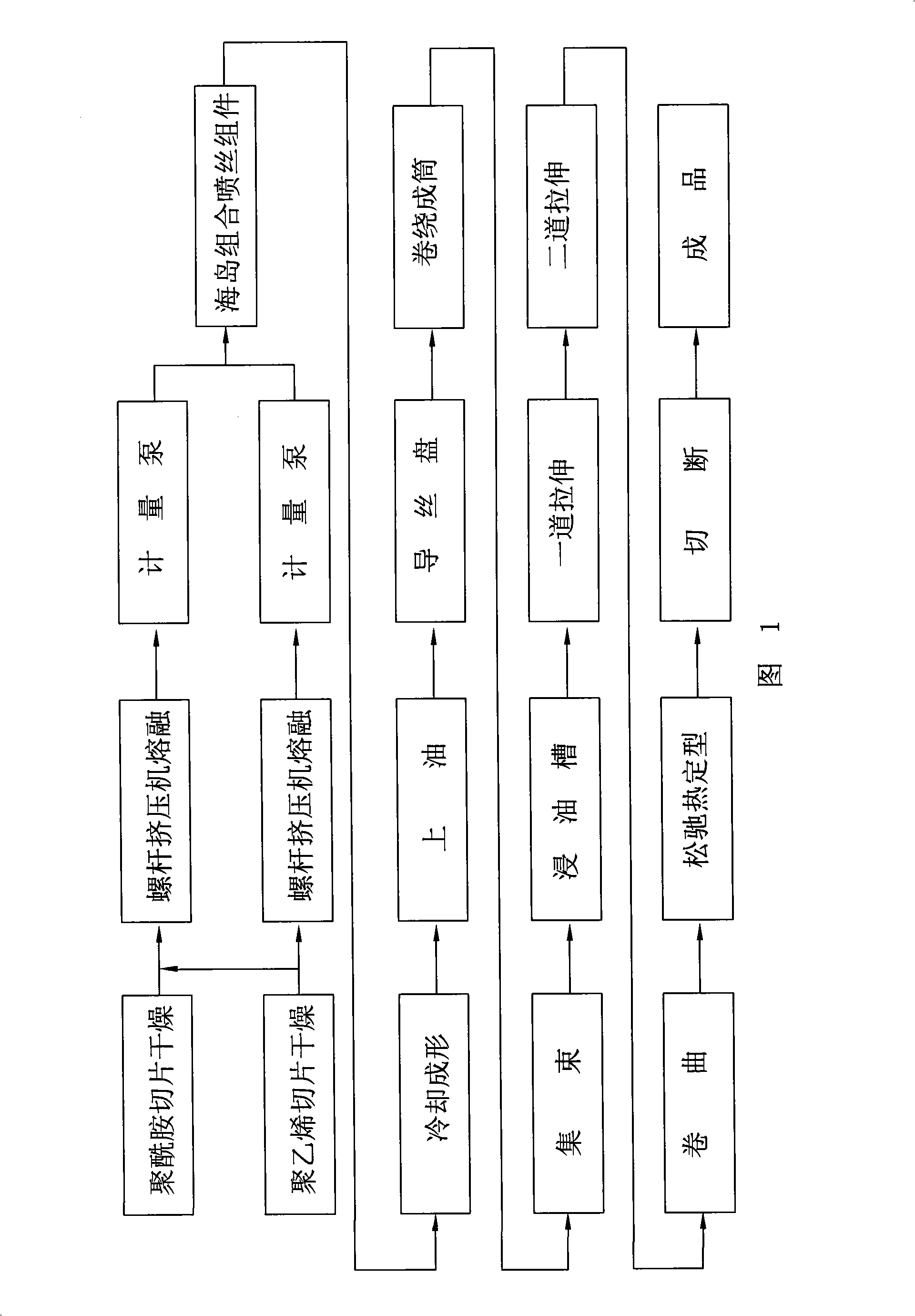

Method used

Image

Examples

Embodiment 1

[0076] PA6 / LDPE+PA6 (LDPE MI=50) spinning process

[0077] The PA6 pump supply is 13.5g / min, the melt spinning temperature is 220-270°C, the screw speed is 12r / min, and the screw pressure is 70kg / cm 3 .

[0078] Sea component (PA6:LDPE=1:1) pump supply rate 9.56g / min, melt spinning temperature 170-275°C, screw speed 21-22r / min, screw pressure 52-62kg / cm 2 .

[0079] The spinning speed is 300m / min. After the spinning is normal, continue to increase the spinning speed to 900m / min and 1100m / min to wind smoothly. Fuzz appears when the spinning speed is increased to 1200m / min, so the spinning speed should be controlled below 1100m / min.

[0080] The above-mentioned winding yarn with a spinning speed of 300m / min is stretched 2.5 times, the fiber breaking strength is 3.09CN / dtex, and the breaking elongation is 140.0%. Stretched 3 times, the fiber breaking strength is 3.72CN / dtex, and the breaking elongation is 115.7%. Stretched 3.5 times, the fiber breaking strength is 4.48CN / dte...

Embodiment 2

[0083] PA6 / LDPE (MI=50) spinning process

[0084] The PA6 pump supply is 13.5g / min, the melt spinning temperature is 220-270°C, the screw speed is 12r / min, and the screw pressure is 97kg / cm 3 .

[0085] Sea component (PA6:LDPE=1:2) pump supply rate 11.5g / min, melt spinning temperature 170-275°C, screw speed 29r / min, screw pressure 60kg / cm 2 .

[0086] The above spinning process stretches 3.5 times, the fiber breaking strength is 3.91CN / dtex, and the breaking elongation is 104.8%. The above winding filaments are bundled into 40,000 deniers, and then enter the first and second drafting rollers for room temperature stretching through the oil immersion tank (the concentration of oil agent is 4-5%), and then the tows enter the crimping machine through a 70°C preheating box . The crimped tow is relaxed and shaped for 10 minutes at a drying temperature of 70-75°C by a chain plate dryer, and then cut by a cutting machine. The number of crimps is 11.5 pieces / 25mm.

Embodiment 3

[0088] PA6 / LDPE(MI=38) spinning industry sesame

[0089] The PA6 pump supply is 13g / min, the melt spinning temperature is 220-270°C, the screw speed is 12-13r / min, and the screw pressure is 67kg / cm 3 .

[0090] The sea component (PA6: LDPE = 1: 1) pump supply rate is 8.5g / min, the melt spinning temperature is 170-275°C, the screw speed is 29r / min, the obtained fiber is drawn 3.3 times, and the single filament fineness is 6dtex. The breaking strength is 4.50CN / dtex, the breaking elongation is 110.0%, the fiber PA6 content is 80%, the fiber strength is high, and the elongation is large. The product is extracted with toluene, and the sea components are dissolved. The single-filament fineness of the satellite island is 0.03dtex, and the single-filament fineness of the main island is 0.22dtex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com