PEVA film for laundry basket and preparation method for PEVA film

A technology of resins and additives, applied in the field of film materials, can solve the problems that canvas needs to be dyed by dyeing factories, products are prone to scratches, and dirty clothes have no place to be placed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of preparation method of laundry basket PEVA film, described preparation method comprises the following steps:

[0035] 1) Weigh the raw materials according to the weight ratio of each component of the PEVA film used in the laundry basket, and pour EVA resin, PE resin, MPE resin, EVA masterbatch, fluoropolymer processing aids and other additives into the high-speed mixer Stir and mix evenly, then blend, melt and extrude through a casting machine, and cast through a flat die head to obtain a PEVA film semi-finished product; wherein, the temperature of each section of the casting machine is set as follows: the temperature of the barrel is 150-160 °C, The filter temperature is 160-170°C, the elbow temperature is 160-170°C, the connection temperature is 160-170°C, and the die head temperature is 160-170°C;

[0036] 2) cooling and shaping the PEVA film semi-finished product in the molten state in step 1), and then using embossing rollers and rubber rollers to carry ou...

Embodiment 1

[0039] A kind of preparation method of laundry basket PEVA film, it comprises the following steps:

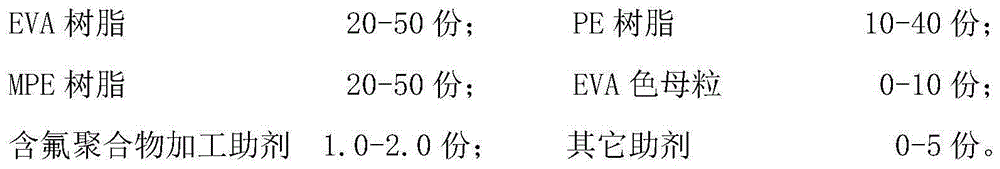

[0040] 1) Take the raw materials according to the weight ratio of each component of the PEVA film for the laundry basket, which includes the following components by weight:

[0041]

[0042] Pour the above-mentioned EVA resin, PE resin, MPE resin, EVA color masterbatch, fluoropolymer processing aids and other additives into a high-speed mixer and mix them evenly, then blend, melt and extrude through a casting machine. The PEVA film semi-finished product is obtained through flat die casting; among them, the temperature of each section of the casting machine is set as follows: the temperature of the barrel is 150-160 °C, the temperature of the filter is 160-170 °C, the temperature of the elbow is 160-170 °C, the connection Temperature 160-170°C, die head temperature 160-170°C;

[0043] 2) cooling and shaping the PEVA film semi-finished product in the molten state in step 1), ...

Embodiment 2

[0046]A kind of preparation method of laundry basket PEVA film, it comprises the following steps:

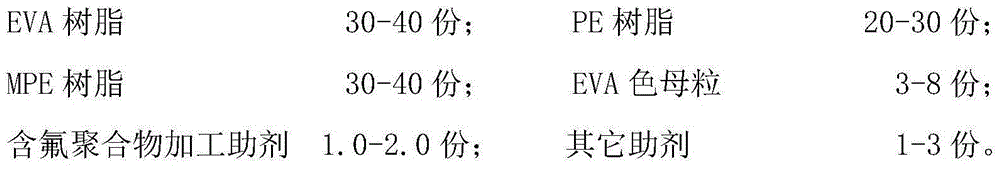

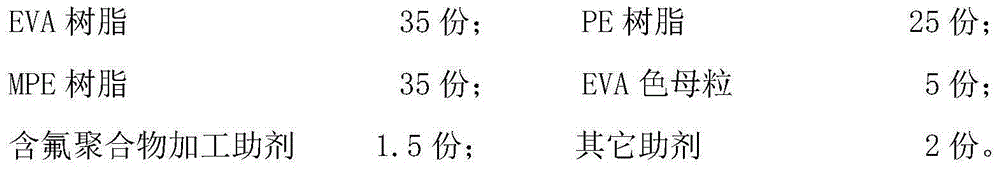

[0047] 1) Take the raw materials according to the weight ratio of each component of the PEVA film for the laundry basket, which includes the following components by weight:

[0048]

[0049] Pour the above-mentioned EVA resin, PE resin, MPE resin, EVA color masterbatch, fluoropolymer processing aids and other additives into a high-speed mixer and mix them evenly, then blend, melt and extrude through a casting machine. The PEVA film semi-finished product is obtained through flat die casting; among them, the temperature of each section of the casting machine is set as follows: the temperature of the barrel is 150-160 °C, the temperature of the filter is 160-170 °C, the temperature of the elbow is 160-170 °C, the connection Temperature 160-170°C, die head temperature 160-170°C;

[0050] 2) cooling and shaping the PEVA film semi-finished product in the molten state in step 1), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com