A scratch-resistant garment dyeing process

A garment dyeing and anti-scratch technology, applied in the field of dyeing technology, can solve the problems of scratched clothes and unqualified products for travel, and achieve the effect of reducing waste, dyeing and dehydration convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

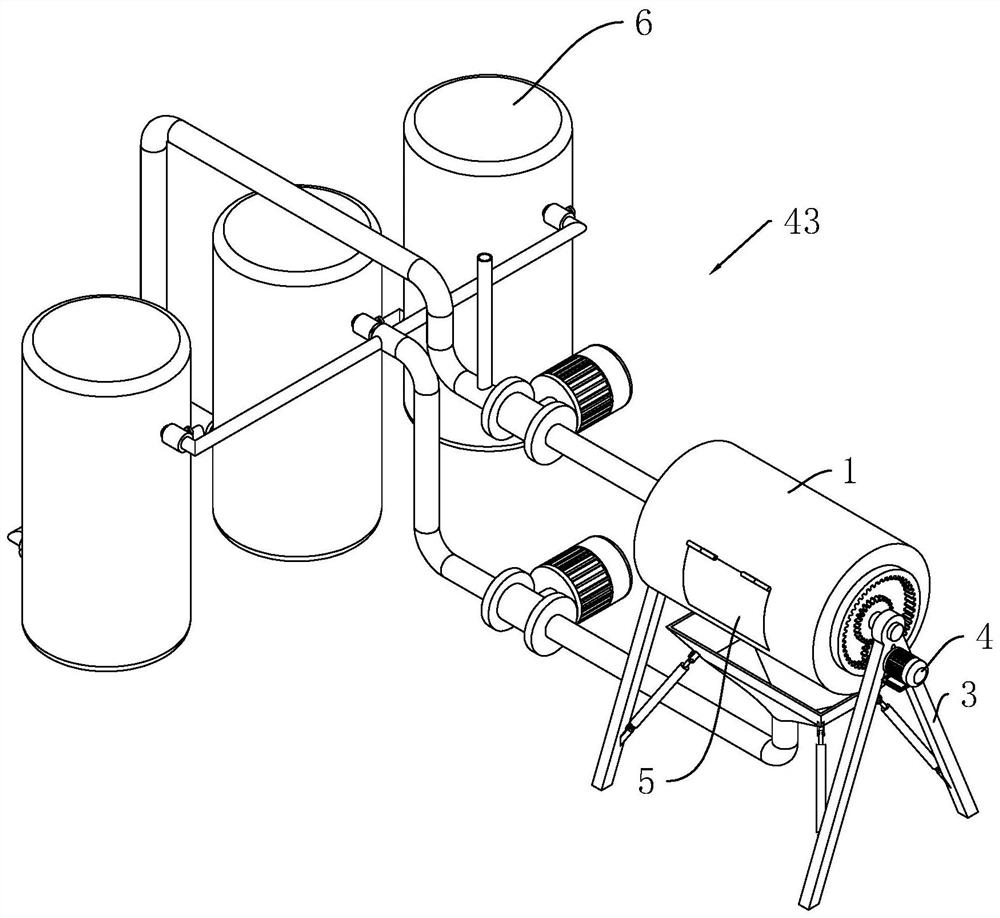

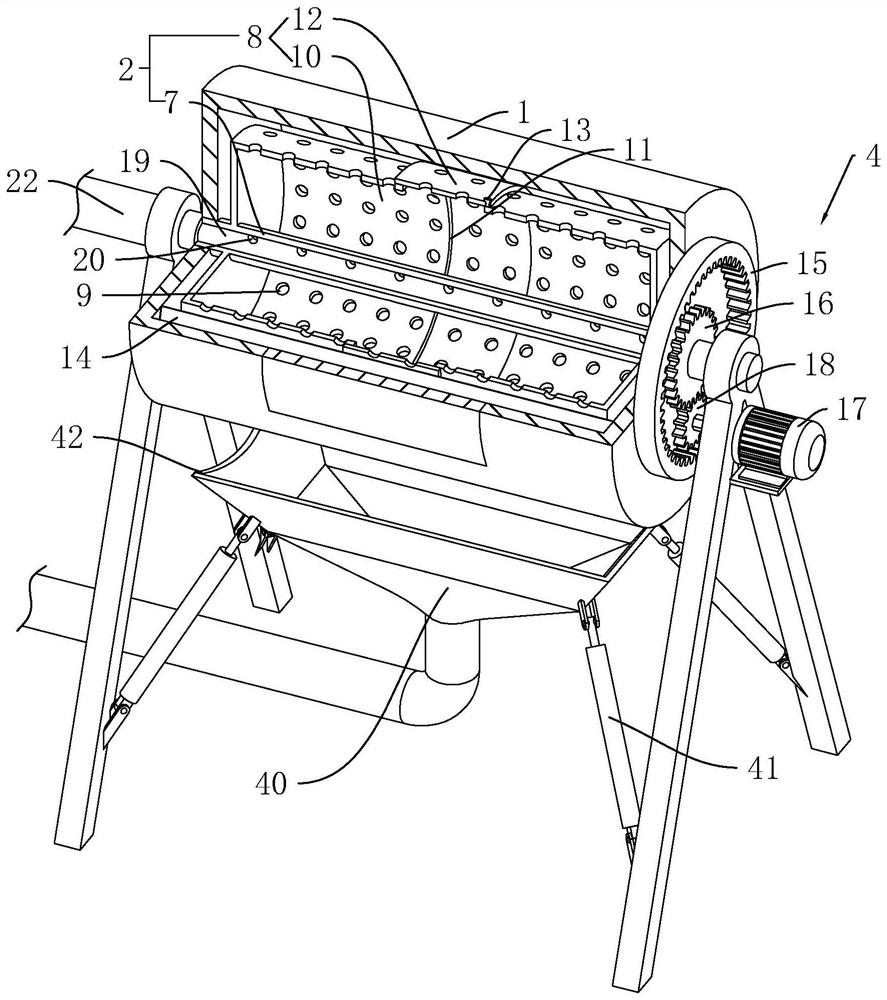

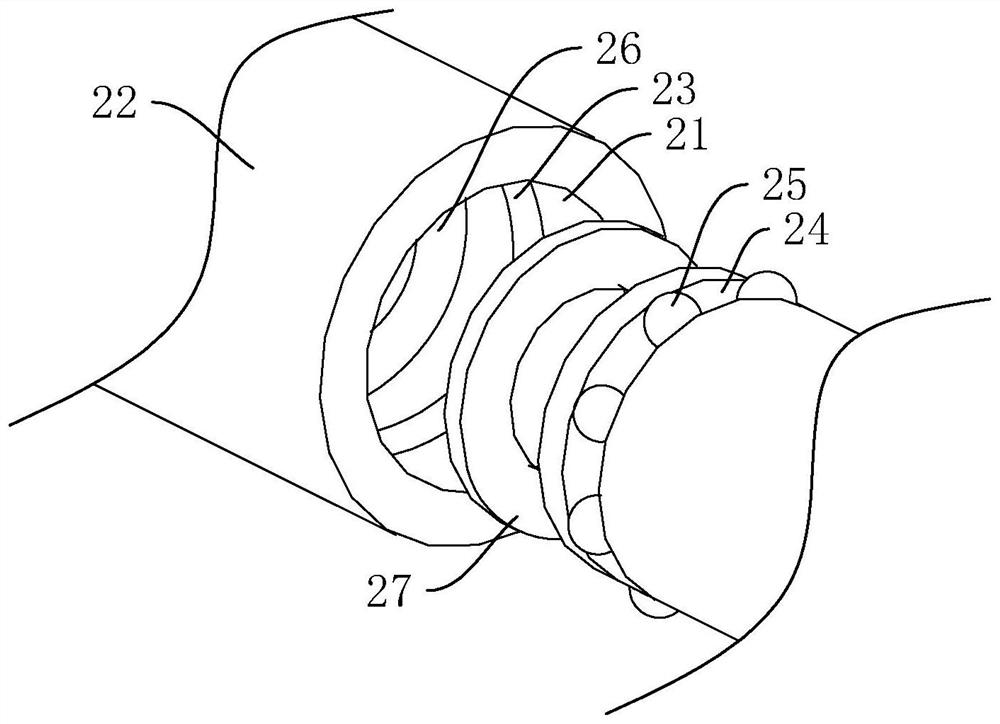

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] A scratch-resistant garment dyeing process, comprising the steps of:

[0037] Step S1: Desizing, padding the nylon clothes in a desizing agent. The desizing agent is a solution mixed with desizing enzyme, so that the desizing enzyme is contaminated on the clothes, and then the clothes are placed on the conveyor belt, and the clothes are driven by the conveyor belt into a desizing box filled with steam for desizing, so that the clothes are desizing in In the steam environment for 3~5 minutes, use the desizing enzyme to desizing the clothes to reduce the damage of the desizing agent to the clothes.

[0038] Step S2: washing, placing the desized clothes in clean water for washing, taking out the desizing enzyme on the clothes, and reducing the influence of the desizing enzyme on the dyeing.

[0039]Step S3: dyeing, each piece of clothing is individually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com