Portable food processor with good heating effect

A technology for food processors and heating effects, which is applied to utensils with integral electric heating devices, cooking utensils, household utensils, etc., and can solve the problem of food fine particles or slurry residues, reduced processing effects of food processors, and production costs of food processors Advanced problems, to achieve the effect of improving cooking effect, improving user satisfaction, and better cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

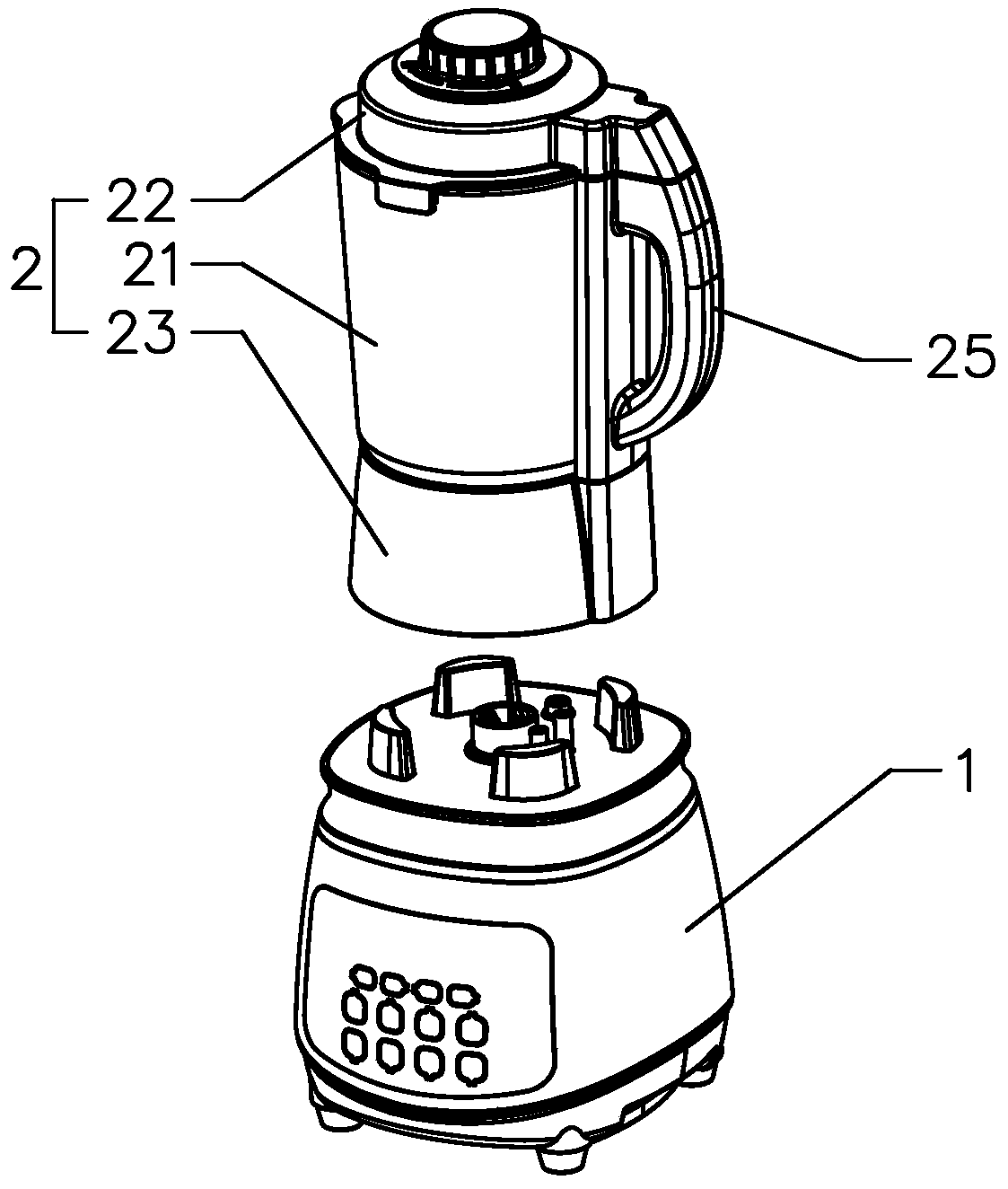

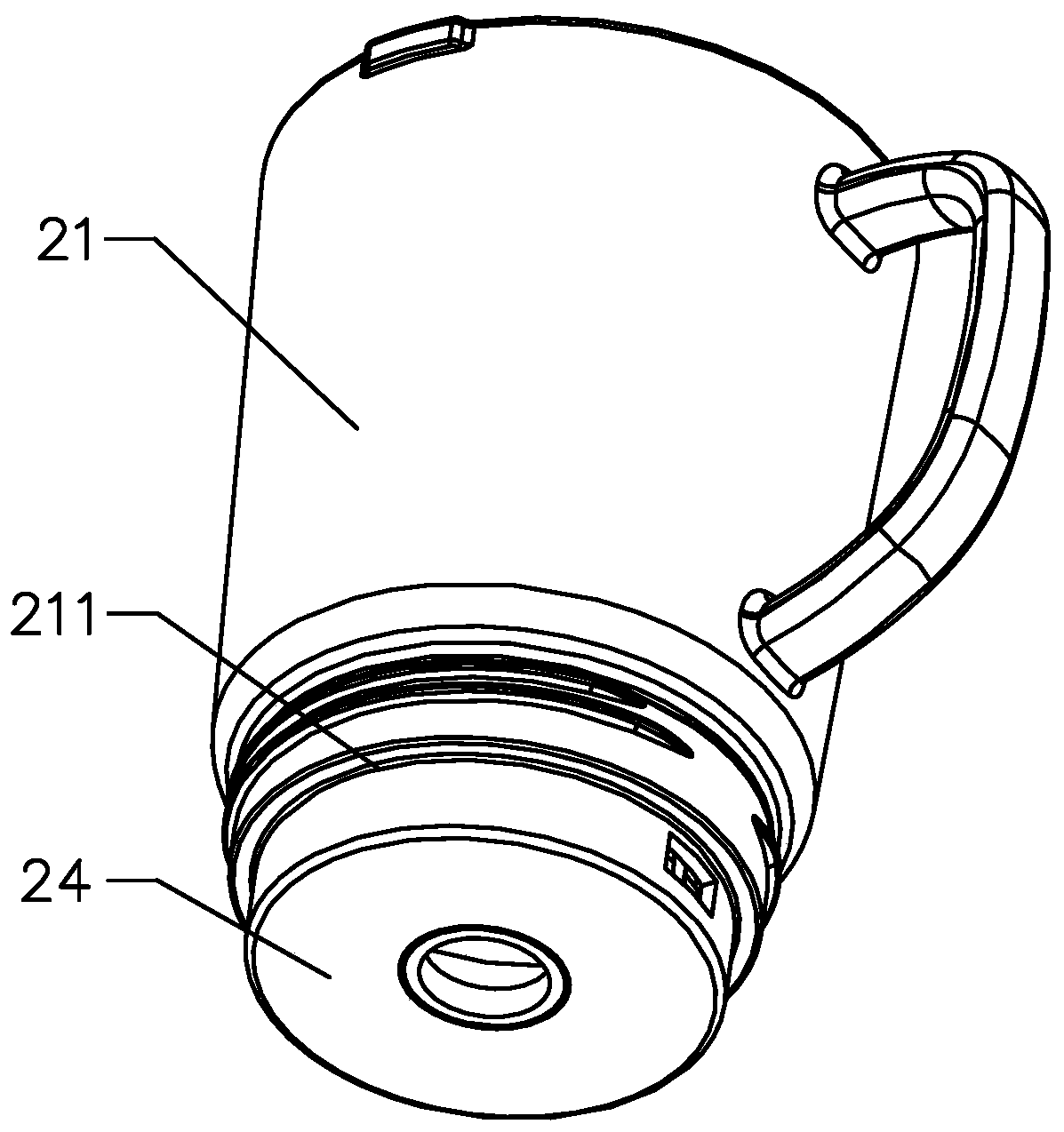

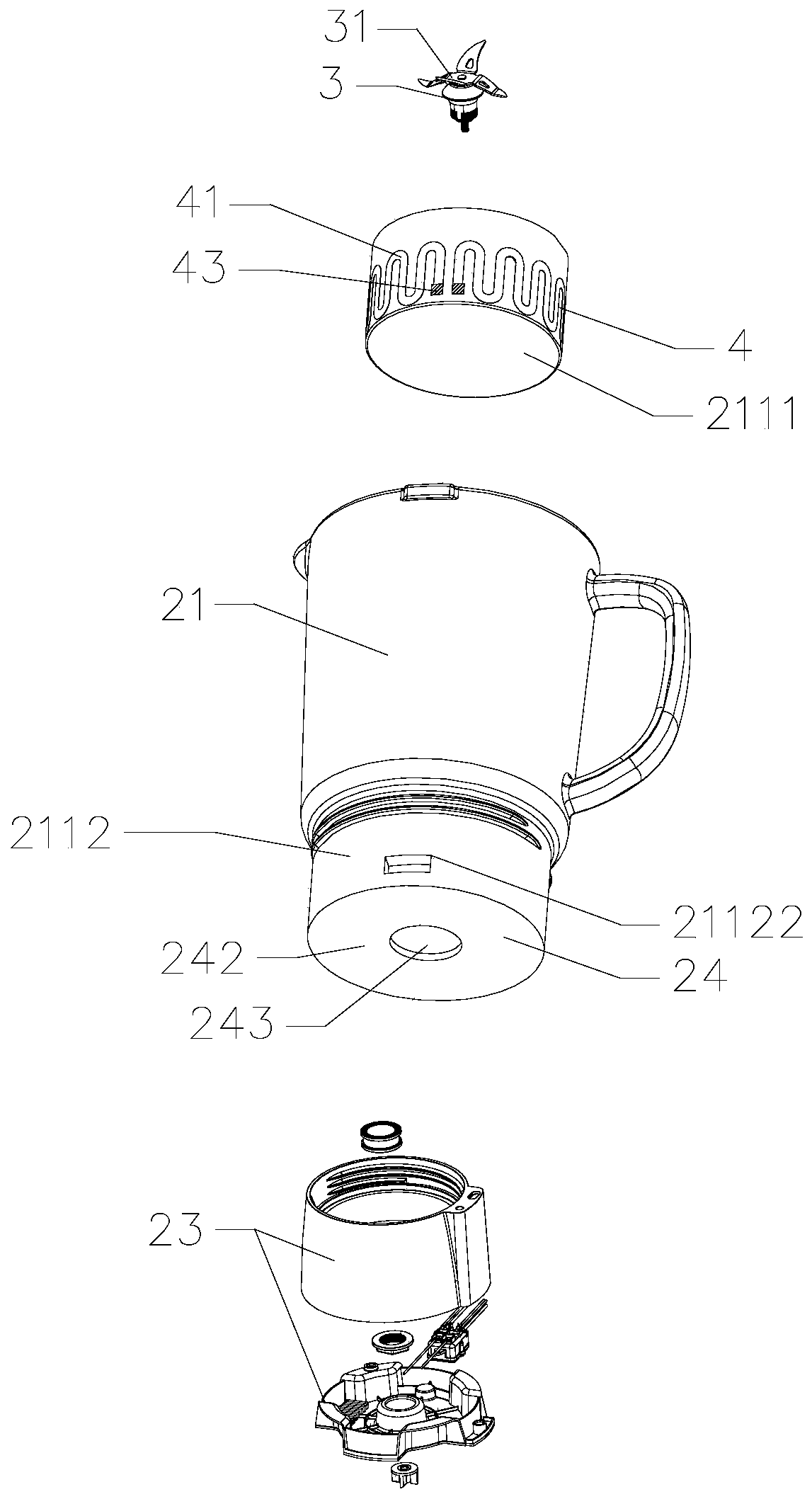

[0042] Such as Figures 1 to 5 As shown, the present invention provides a food processor with good heating effect, which includes a machine base 1, a stirring cup 2 and a heating device. The stirring cup 2 includes a ceramic cup body 21, a cup cover 22 and a cup bottom 24. There is a crushing knife 31, the upper port of the ceramic cup body 21 is covered with a cup cover 22, the lower port of the ceramic cup body 21 is provided with a cup bottom 24, and the motor base 1 is provided with a motor (not shown) and The control board (not shown in the figure), the motor drives the pulverizing knife 31 to rotate, so as to realize the stirring and pulverizing of the slurry or material.

[0043] In this embodiment, both the cup body and the cup bottom are made of ceramics, the heating device includes a heating element 4, the cup body 21 includes a heating section 211, and the heating section 211 includes a food-grade ceramic inner layer 2111, coating The food-grade ceramic outer layer...

Embodiment 2

[0059] The difference between this embodiment and the first embodiment is that the bottom of the cup is integrated with the cup body through secondary molding, and the structure of the heating element and the processing and molding method of the ceramic cup body are different.

[0060] In this example, if Figure 6 As shown, the stirring cup includes a ceramic cup body 21 and a ceramic cup bottom 24. The ceramic cup body 21 includes a heating section 211, and the heating section 211 includes a food-grade ceramic inner layer 2111, and food-grade ceramics coated outside the food-grade ceramic inner layer 2111. The outer layer 2112 and the heating element 4 electrically connected to the control board, the cup bottom 24 are integrated with the cup body 21 through secondary molding, specifically through hot pressing forming, after the ceramic cup body 21 and the ceramic cup bottom 24 are integrated, stir Cup 2 has an overall smooth appearance, does not scratch hands, and has no steps...

Embodiment 3

[0067] The difference between this embodiment and the second embodiment is that a heating device is also provided on the bottom of the cup.

[0068] Such as Figure 8 and 9 As shown, the food processing machine is provided with a heating section 211 on the ceramic cup body 21, and the structure of the heating element 4 provided on the heating section 211 of the ceramic cup body 21 is consistent with the second embodiment, but the food-grade ceramics in this embodiment The outer layer 2112 is not provided with a limiting groove, and the heating element 4 is directly sintered or glued or welded on the lower part of the inner wall of the food-grade ceramic outer layer 2112. In this embodiment, except that the heating section 211 is provided with the heating element 4, the stirring The cup bottom 24 of the cup 2 is also provided with a heating device 5, the height of the heating section 211 is H1, the height of the cup body 21 is H2, 0.2≤H1 / H2≤0.5, because in this embodiment, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com