Portable food processor with high heating efficiency

A food processing machine and machine base technology, which is applied in the direction of utensils with integral electric heating devices, cooking utensils, household appliances, etc., can solve the problem of reduced processing efficiency of food processors, unguaranteed production efficiency, and difficulties in the design and processing of mixing cups and other problems, to achieve the effect of improving cooking effect, improving user satisfaction, and good cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

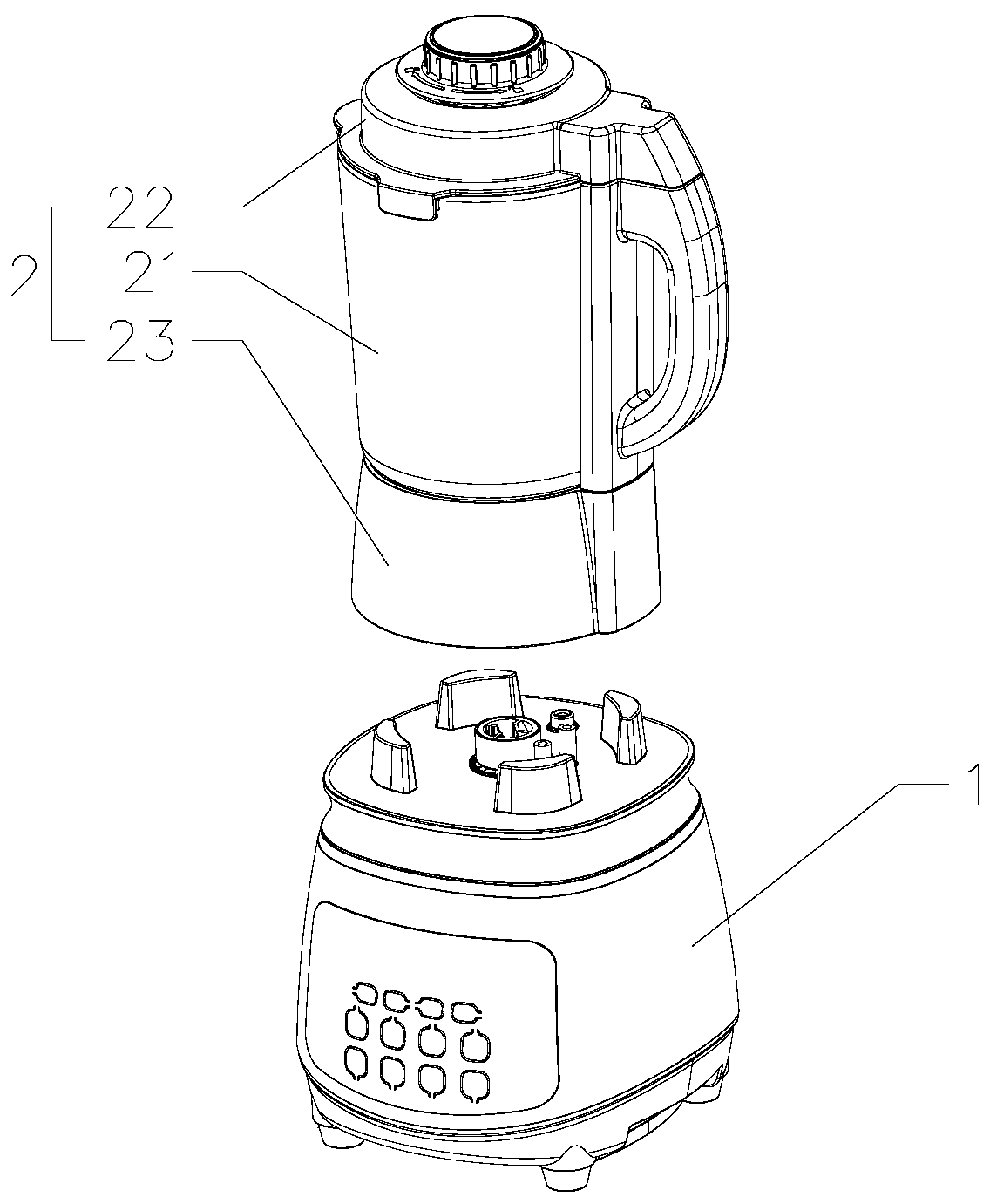

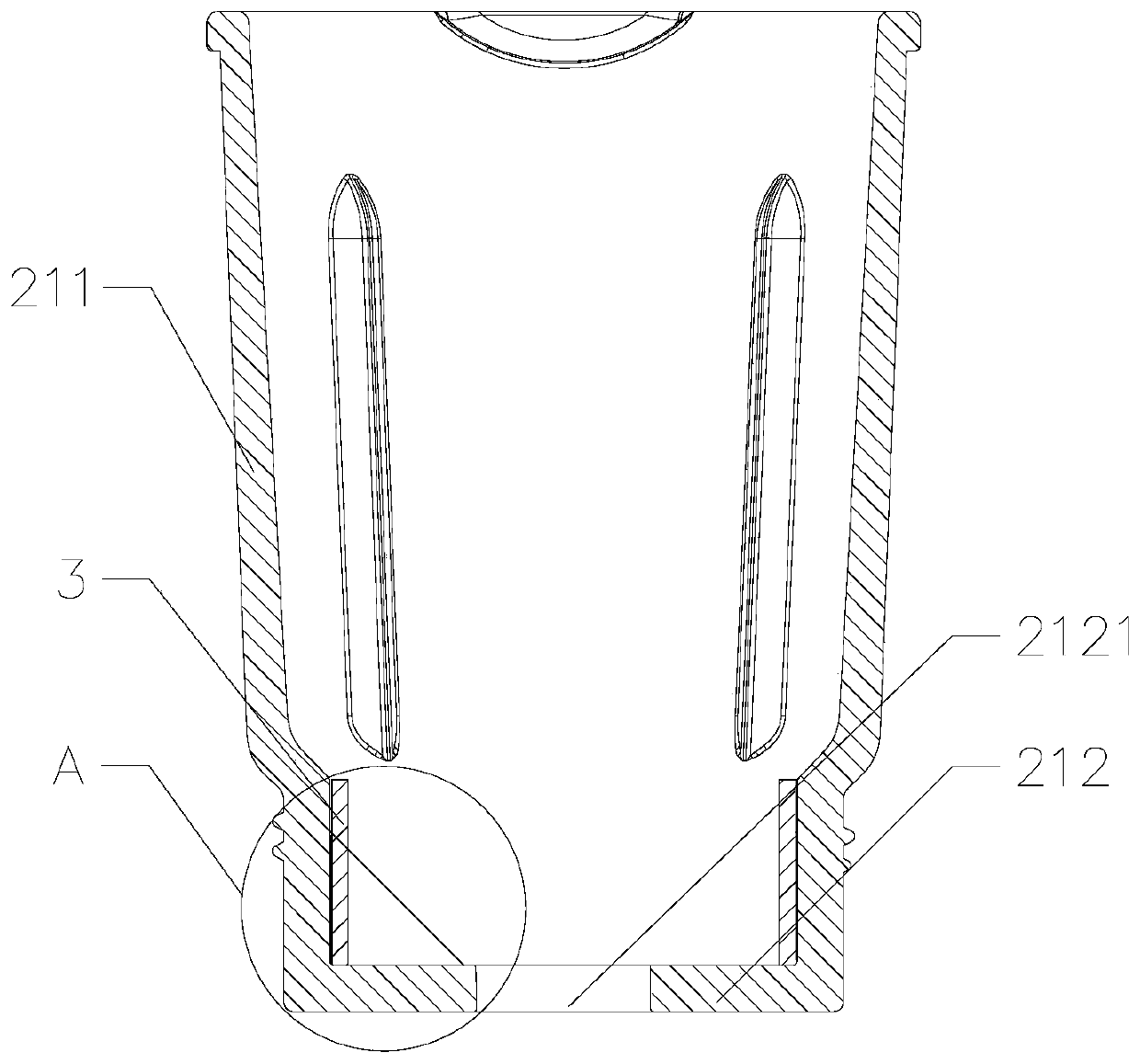

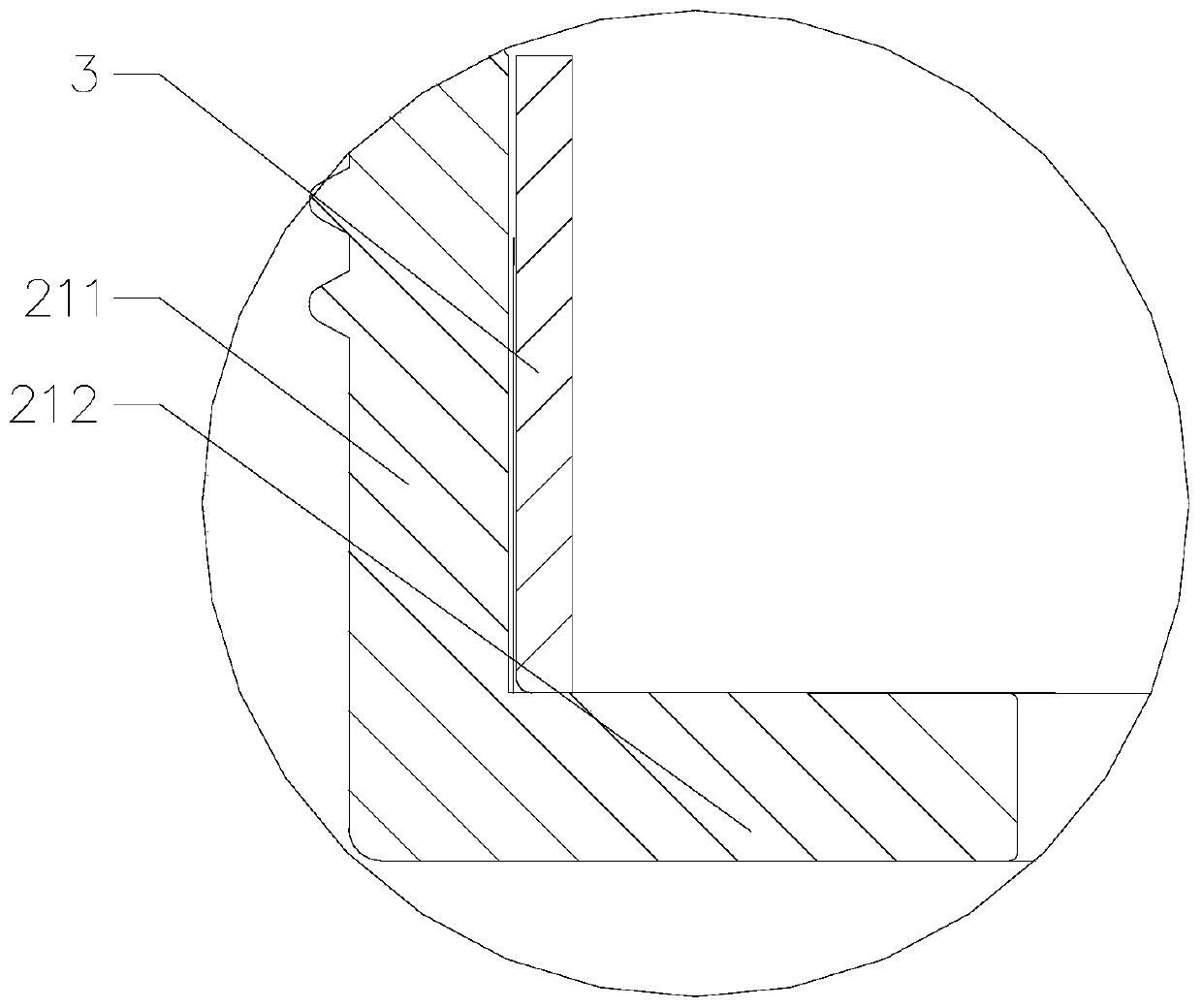

[0052] Such as Figures 1 to 4 As shown, the present invention provides a food processor with high heating efficiency, including a machine base 1 and a stirring cup 2, the stirring cup 2 is provided with a pulverizing knife assembly, and the pulverizing knife assembly includes a knife shaft and a pulverizing knife arranged on the top of the knife shaft , the machine base 1 is provided with a motor and a control board, the motor drives the pulverizer to rotate, the stirring cup 2 includes a cup body 21, a cup cover 22 and a cup holder 23, the cup cover 22 is rotated and buckled on the top of the cup body 21, and the cup holder 23 is connected At the bottom of the cup body 21, the cup body 21 includes a cup body 211 and a cup bottom 212, the cup bottom 212 is provided with a mounting hole 2121, the crushing knife assembly is located in the mounting hole 2121, and the knife shaft with the crushing knife on the top extends through the mounting hole into the cup.

[0053] In this ...

Embodiment 2

[0063] The difference between this embodiment and the first embodiment lies in that the electrical connection method of the first heating element is different, and the installation structure of the first insulating film base is different.

[0064] In this example, if Figures 5 to 6 As shown, the lower end of the first insulating film substrate 31 protrudes from the bottom of the cup 212, and the cup bottom 212 is provided with a through hole for the lower end of the first insulating film substrate 31 to protrude, and the first conductive terminal 33 is located on the bottom of the cup. On the first insulating film substrate 31 of the cup bottom 212, the first conductive terminal 33 is electrically connected to the control board through a wire, so that the electrical connection between the first heating element and the control board can also be well realized. , and the electrical connection is reliable and convenient.

[0065] And, the inner wall of the lower end of the cup b...

Embodiment 3

[0069] The difference between the present embodiment and the first embodiment lies in that the cup body and the cup bottom have separate structures.

[0070] In this example, if Figures 7 to 8 As shown, the cup body 211 and the cup bottom 212 have separate structures, and the longitudinal section of the cup bottom 211 is type, the side wall of the cup bottom 212 and the inner side wall of the cup body 211 are bonded together through secondary fixing and sealing. In addition, the connection area between the cup bottom and the cup body of this structure is enlarged, which facilitates its connection and installation with the cup body, and at the same time, it can well ensure the connection between the cup bottom and the cup body. The tightness between the cups prevents the slurry or ingredients from leaking from the joint between the cup body and the bottom of the cup. In particular, the bottom of the cup is sintered with the body of the cup, so that the waterproof and insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com