Yarn with controllable white cores

A technology of yarn and white core, applied in the field of yarn with controllable white core, can solve the problem of difficult control of white core, and achieve the effect of high twist coefficient and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

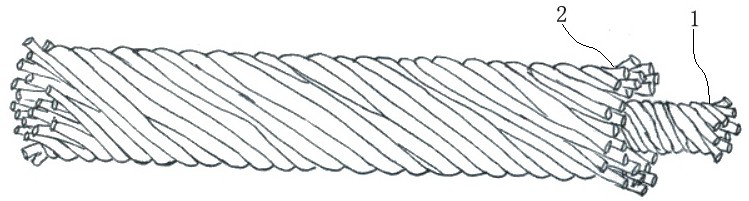

[0018] as attached Figure 1-2 As shown, the yarn with controllable whiteness of the present invention is a warp yarn, and the warp yarn includes an inner yarn core 1 and an outer yarn 2 covered outside the inner yarn core 1; the inner yarn core 1 is A single synthetic staple or a blend of synthetic staples, the outer yarn 2 is a single cellulose staple or a blend of cellulose staples; the warp yarn has a fineness of 6 to 40 pounds, and the inner yarn The fineness of the core 1 is 40-100 lbs; the inner layer yarn core 1 adopts Z twist direction or S twist direction to weave, and the outer layer yarn 2 and the inner layer yarn core 1 are wrapped with the inner layer yarn Core 1 is spun with the same twist direction, the twist coefficient of the inner layer yarn core 1 is 350~520 after spinning, and the twist coefficient of the outer layer yarn 2 is 300~350.

[0019] The single synthetic fiber staple of the inner layer yarn core of the present invention is polyester, nylon, pol...

Embodiment 2

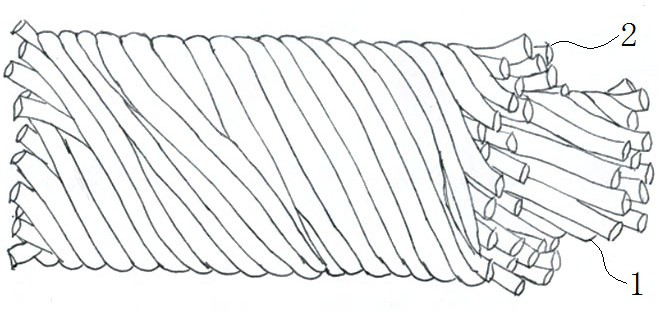

[0036] as attached Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is: after the outer layer yarn 2 is covered with the inner layer yarn 1 core, the twist direction opposite to that of the inner layer yarn core 1 is used for weaving, and the inner layer yarn core 1 is twisted after spinning. The twist coefficient is 300-350, and the twist coefficient of the outer yarn 2 is 350-520.

[0037] During the specific application of this embodiment, the proportioning of raw materials and the production conditions of the following embodiments can be adopted:

[0038] Warp fineness Inner yarn core fineness Inner yarn core twist coefficient Outer yarn twist coefficient white core example 1 10 lbs 40 lbs 300 450 25% Example 2 10 lbs 60 lbs 300 450 15%

[0039] It can be seen from the example in the above table that as long as the fineness of the inner yarn core 1 and the overall warp yarn is controlled, the whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com