Double-sided differential knitted fabric and its weaving process

A technology of double-sided difference and knitted fabrics, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of prone to wrong stitches, not suitable for making spring and autumn clothing, jumpers, etc., and achieve good wearing comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

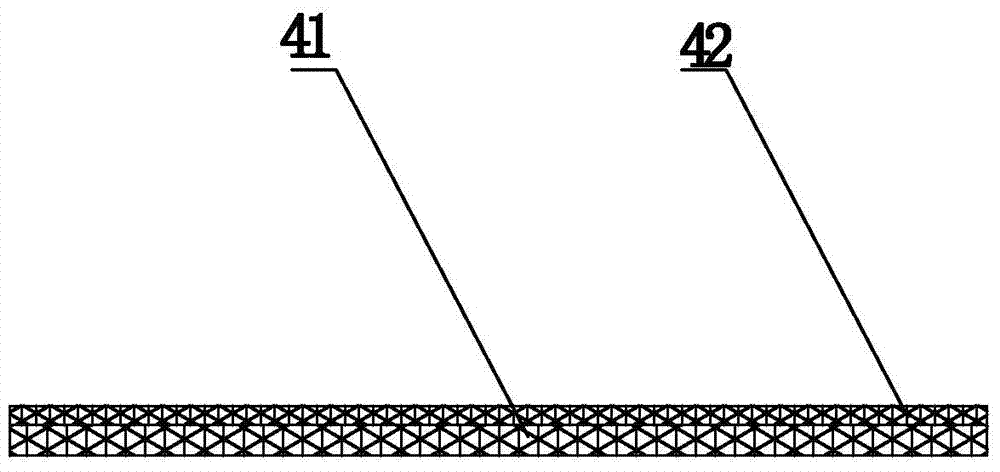

[0030] In this embodiment, the double-sided differential knitted fabric is combined with figure 1 , consisting of a front 41 and a back 42, the back 41 is woven with a low needle level, and the front is woven with a high needle level or mixed with a low needle level and a high needle level.

[0031] The weaving process of the above-mentioned double-sided differential knitted fabric is as follows:

[0032] The yarn or fiber is carried out on the double-sided differential needle cylinder, which is composed of the upper needle cylinder 1 and the lower needle cylinder 2, and the upper needle cylinder 1 and the lower needle cylinder 2 are respectively provided with spacers 3, The spacing between adjacent spacers 3 is in a changing state, and the spacing is set at a dense interval; combined with Figure 5 , the top surface of the upper needle cylinder 1 has a slope structure; the yarn or fiber passes through the upper needle cylinder 1 and the lower needle cylinder 2 in sequence, a...

Embodiment 2

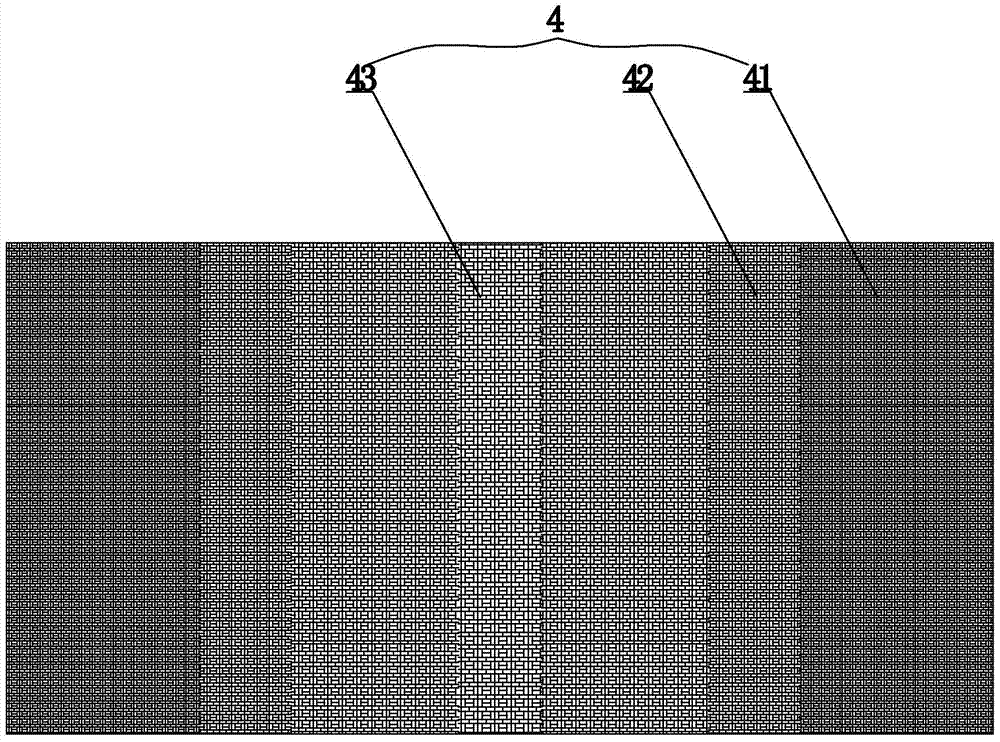

[0035] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that: on the upper needle cylinder 1, the distance between adjacent spacers gradually increases first, then gradually decreases, then gradually increases, and then circulates successively to form a dense interval structure; on the lower needle cylinder 2, the spacing between adjacent spacers is the same, and the spacing is not less than the minimum spacing between adjacent spacers on the upper needle cylinder 1; figure 2 The structure shown includes a dense region 41, a transition region 42 and a fluffy region 43; wherein, the dense region 41 is woven with a low needle grade, and the fluffy region 42 is woven with a high needle grade.

Embodiment 3

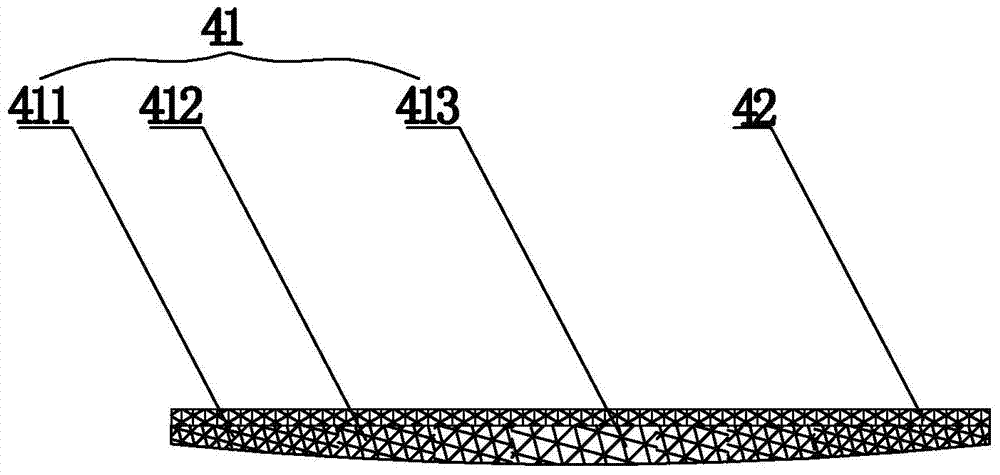

[0037] In this embodiment, the double-sided differential knitted fabric is combined with figure 2 , consisting of a front 41 and a back 42, the back 41 is woven with a low needle level, and the front is woven with a high needle level or mixed with a low needle level and a high needle level. Specifically in this embodiment, combined with image 3 , the front side 41 includes a dense area 411, a fluffy area 413 and a transition area 412 arranged alternately, the transition area 412 is arranged between the dense area 411 and the fluffy area 413, and the density of the transition area 412 is between the dense area 411 and the fluffy area 413 , and connect the dense area 411 and the fluffy area 413 together in a gradual manner, from figure 2 It can also be seen from the cross-sectional view that the fluffy region 413 is higher than the dense region 411.

[0038] The weaving process of the above-mentioned double-sided differential knitted fabric is as follows: the yarn or fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com