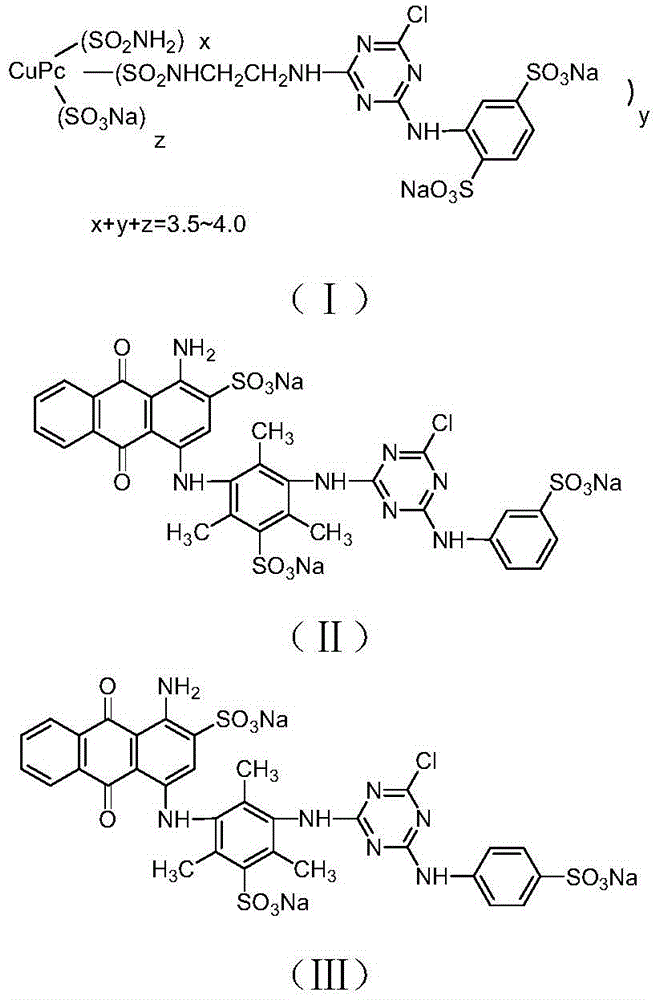

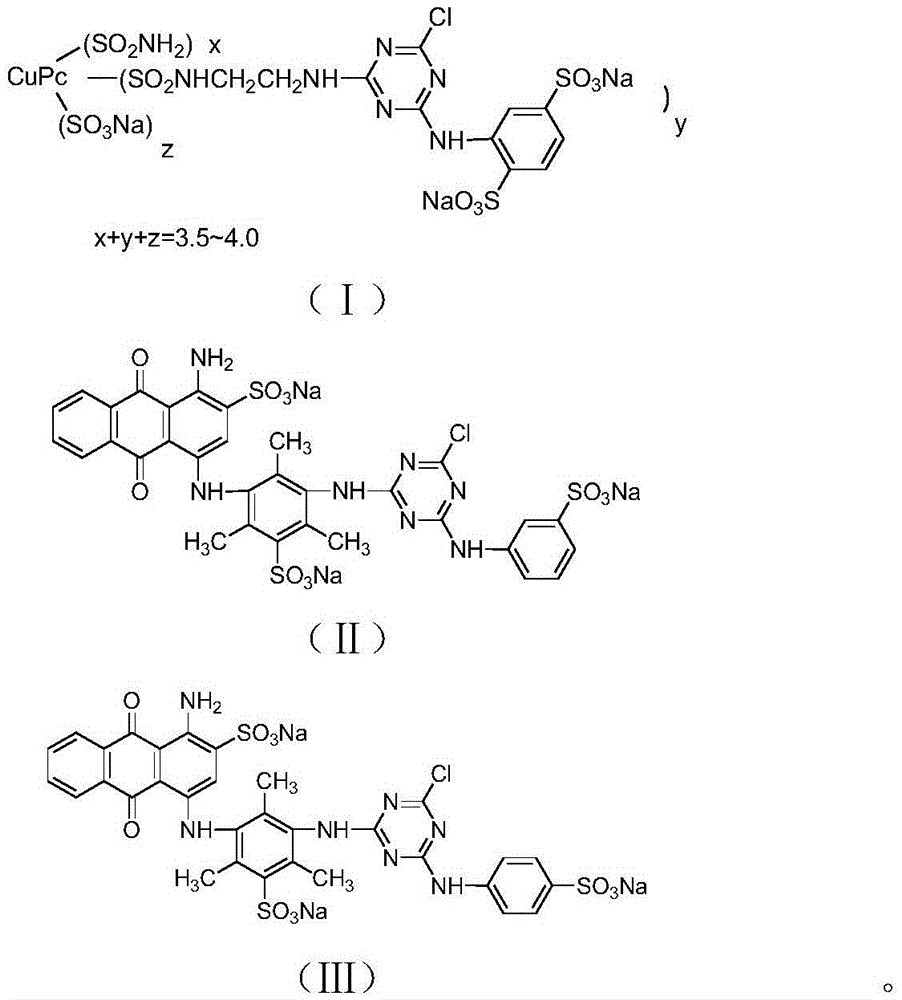

A kind of brilliant blue reactive dye mixture and its application

A technology of reactive dyes and mixtures, which is applied to resist dyeing and printing applications on cellulose fiber fabrics, in the field of brilliant blue reactive dyes, can solve problems such as defects, environmental pollution, and framing, improve fastness properties, and overcome white cloth staining. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Compound shown in structural formula (I), (II) is mixed according to the mass percentage of 65% and 35%, and brilliant blue active dye mixture is obtained; With brilliant blue active dye mixture 65%, diffusing agent (naphthalenesulfonic acid , the sulfonation degree is 1) 10%, water-based dustproof agent 0.5%, Yuanming powder 14.5% and nonionic leveling agent (ethylene oxide condensate, condensation degree is 200) 10%, mix and make commodity dyestuff;

[0026] Take 5 parts of the above commercial dyes, add 7 parts of urea, 1 part of resist salt S, 2 parts of baking soda, 70 parts of resist paste and 15 parts of hot water to make dyeing paste, and carry out resist printing and dyeing on cotton fabrics according to the conventional operation method , dried with hot air at 90°C, steamed with saturated steam at 102°C for 7 minutes, and finally washed with hot water, cold water, soaped, washed with water, and dried to obtain a bright blue cotton fabric. The results of the co...

Embodiment 2

[0028] The compounds shown in structural formula (I), (III) are blended according to the weight percentage of 55% and 45%, and the brilliant blue reactive dye mixture is obtained; 80% of the brilliant blue reactive dye mixture, the diffusing agent (methyl naphthalene Sulfonic acid formaldehyde condensate, condensation degree is 4, sulfonation degree is 1) 8%, water-based dustproof agent 0.1%, Yuanming powder 6.9% and non-ionic leveling agent (ethylene oxide condensation product, condensation degree is 200) 5%, mixed to make commercial dyes;

[0029] Take 5 parts of the above commercial dyes, add 7 parts of urea, 1 part of resist salt S, 2 parts of baking soda, 70 parts of resist paste and 15 parts of hot water to make dyeing paste, and carry out resist printing and dyeing printing on leather fabrics according to the conventional operation method , air-dried with hot air at 90°C, steamed with saturated steam at 102°C for 7 minutes, and finally washed with hot water, cold water,...

Embodiment 3

[0031] Compounds shown in structural formula (I), (II), and (III) are blended according to 64%, 18%, and 18% by weight to obtain a brilliant blue reactive dye mixture; 70% of the brilliant blue reactive dye mixture , diffusion agent (methylnaphthalenesulfonic acid formaldehyde condensate, condensation degree is 2, sulfonation degree is 1) 5%, water-based dustproof agent 0.4%, Yuanming powder 15% and non-ionic leveling agent (ethylene oxide Alkane condensates, the degree of condensation is 200) 9.6%, mixed to make commercial dyes;

[0032] Take 5 parts of the above-mentioned commercial dyes, add 7 parts of urea, 1 part of resist salt S, 2 parts of baking soda, 70 parts of resist paste and 15 parts of hot water to make dyeing paste, and carry out resist printing and dyeing printing on hemp fabric according to the conventional operation method , air-dried with hot air at 90°C, steamed with saturated steam at 102°C for 7 minutes, and finally washed with hot water, cold water, soap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com