A production process of strawberry pulp suitable for hard milk feeding and the application of the strawberry pulp

A production process, strawberry technology, applied in applications, food science, frozen desserts, etc., can solve the problems of destroying the integrity of fruit particles, increasing the coloring of ice cream, increasing production costs, etc. The effect of enhanced sense and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

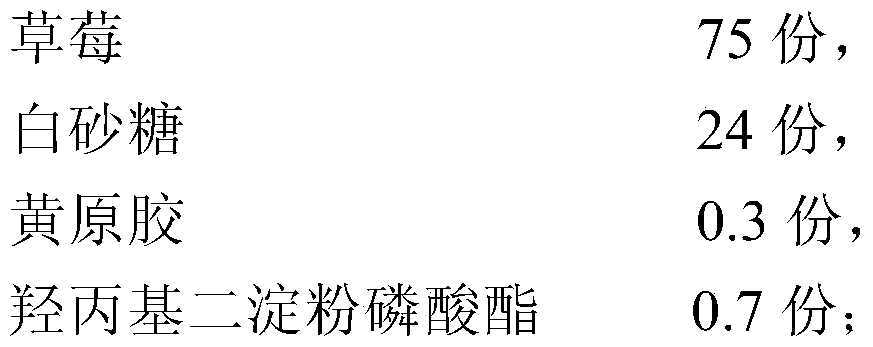

[0048] A kind of formula that is applicable to the strawberry pulp of hard filling milk material of the present invention comprises (in parts by weight):

[0049] 70 servings of strawberries,

[0050] 10 parts white sugar,

[0051] Locust bean gum 0.1 parts,

[0052] The specific production process is as follows:

[0053] Quick-frozen strawberries→dicing→weighing / ingredients (strawberry, thickener, white sugar)→strawberry, thickener, 5% of the total weight of the above-mentioned white sugar for material mixing (3 minutes)→stand for 30 minutes→add the remaining Part of the white sugar → mix the materials evenly → honey staining (30 minutes) → metal detection → sterilization → pouring → refrigerated storage and transportation.

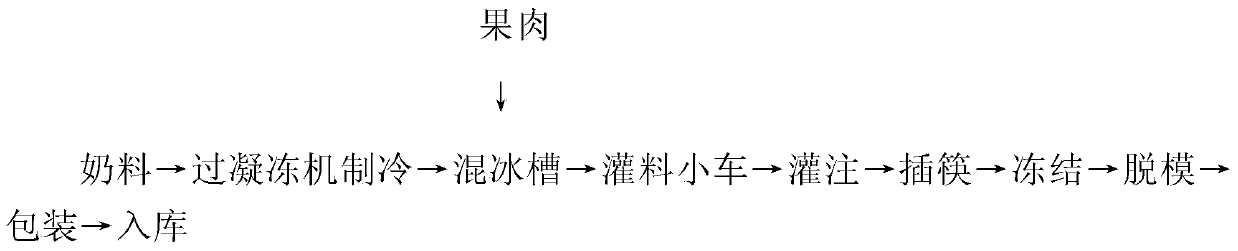

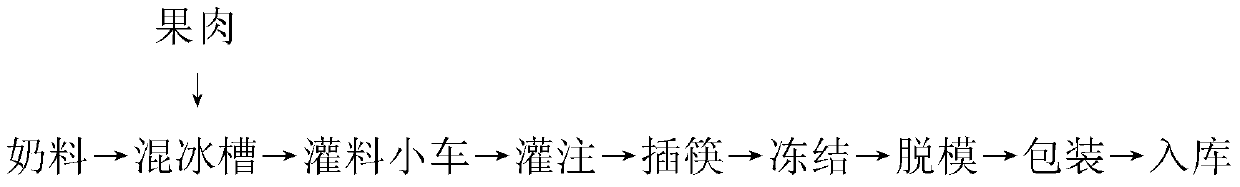

[0054] The production process of the frozen product containing the strawberry pulp prepared by the production process of the present invention is as attached figure 2shown.

[0055] Due to the adoption of the strawberry pulp prepared by the product...

Embodiment 2

[0057] A kind of formula that is applicable to the strawberry pulp of hard filling milk material of the present invention comprises (in parts by weight):

[0058] 90 servings of strawberries,

[0059] 30 parts white sugar,

[0060] 1 part guar gum,

[0061] The specific production process is as follows:

[0062] Quick-frozen strawberries→dicing→weighing / ingredients (strawberry, thickener, white sugar)→strawberry, thickener, 25% of the total weight of the above-mentioned white sugar for material mixing (5 minutes)→stand for 50 minutes→add the remaining Part of the white sugar → mix the materials evenly → honey staining (60 minutes) → metal detection → sterilization → pouring → refrigerated storage and transportation.

[0063] The production process of the frozen product containing the strawberry pulp prepared by the production process of the present invention is as attached figure 2 shown.

[0064] Due to the adoption of the strawberry pulp prepared by the production proc...

Embodiment 3

[0066] A kind of formula that is applicable to the strawberry pulp of hard filling milk material of the present invention comprises (in parts by weight):

[0067] 80 servings of strawberries,

[0068] 20 parts white sugar,

[0069] Sodium carboxymethyl cellulose 0.5 parts

[0070] The specific production process is as follows:

[0071] Quick-frozen strawberries→dicing→weighing / ingredients (strawberry, thickener, white sugar)→strawberry, thickener, 15% of the total weight of the above-mentioned white sugar for material mixing (4 minutes)→stand for 40 minutes→add the remaining Part of the white sugar → mix the materials evenly → honey staining (45 minutes) → metal detection → sterilization → pouring → refrigerated storage and transportation.

[0072] The production process of the frozen product containing the strawberry pulp prepared by the production process of the present invention is as attached figure 2 shown.

[0073] Due to the adoption of the strawberry pulp prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com