Weaving and dyeing method for unidirectional moisture-conducting elastic fabric

A one-way wet and elastic technology, applied in the fields of textile weaving and dyeing and finishing, to achieve good wearing performance and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments.

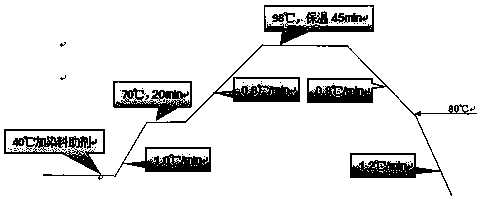

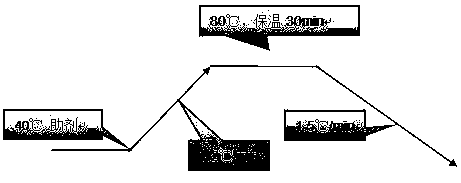

[0019] The invention relates to a weaving and dyeing method for unidirectional moisture-wicking elastic fabrics. The weaving and dyeing process is pulping and weaving→dyeing→finished product inspection, wherein the dyeing is carried out according to the following procedures: cold stacking→loose desizing→presetting→dyeing→ Dehydration and drying-clear water setting; the working fluid for the cold stack is H 2 0 2 , NaOH, penetrating agent, and refining agent are mixed in a weight ratio of 5:10:1:1, and an aqueous solution prepared by adding 30-33 times the total weight of the three deionized water is prepared, and the cold pile time is 24 hours; Described loose type desizing adopts loose type continuous desizing three ways, and described loose type desizing uses working liquid to be by weight ratio 2:1 by NaOH, chelating dispersant, desizing liquid TF-127, deoiling spirit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com