Rolled material for fracture split connecting rod excelling in fracture splittability, hot forged part for fracture split connecting rod excelling in fracture splittability, and fracture split connect

A technology of separated and rolled materials, which is applied in the field of rolling suitable for manufacturing, can solve problems such as large deformation, achieve high strength and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0107] Hereinafter, the present invention is described in more detail by citing the examples, but the present invention is certainly not limited by the following examples, and can also be appropriately modified and implemented within the scope of being able to meet the aforementioned purpose, and these are all included in the technical scope of the present invention .

manufacture example

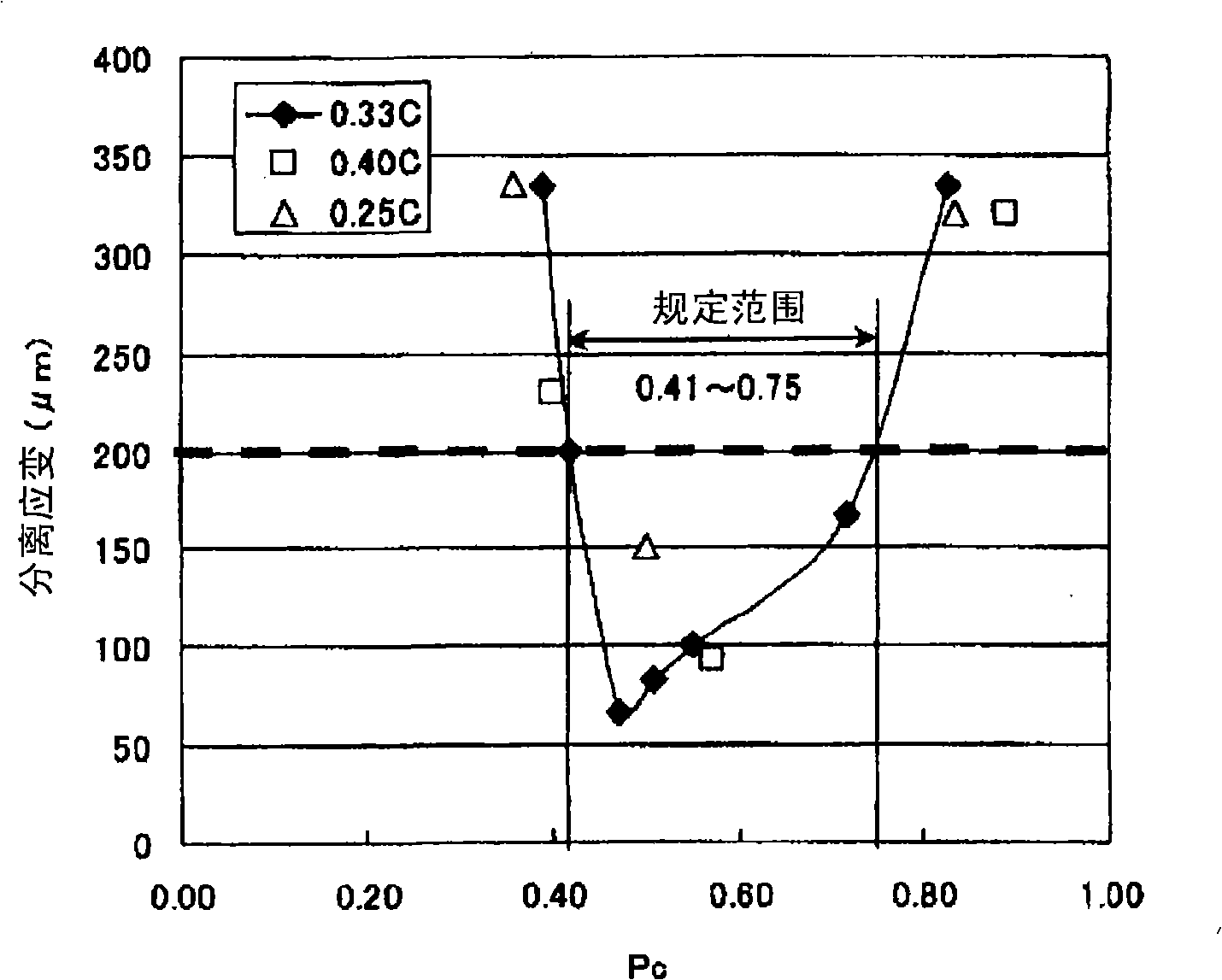

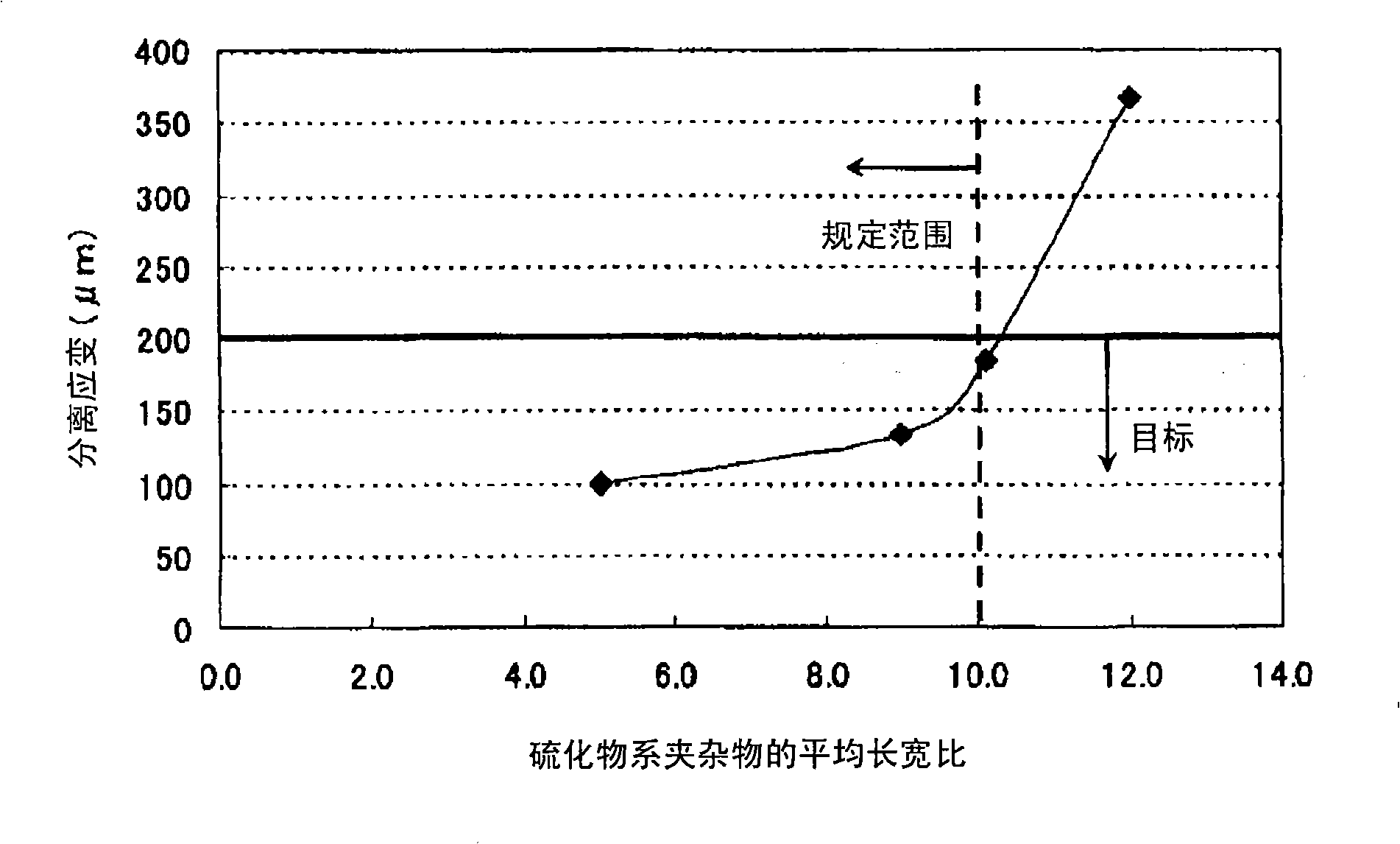

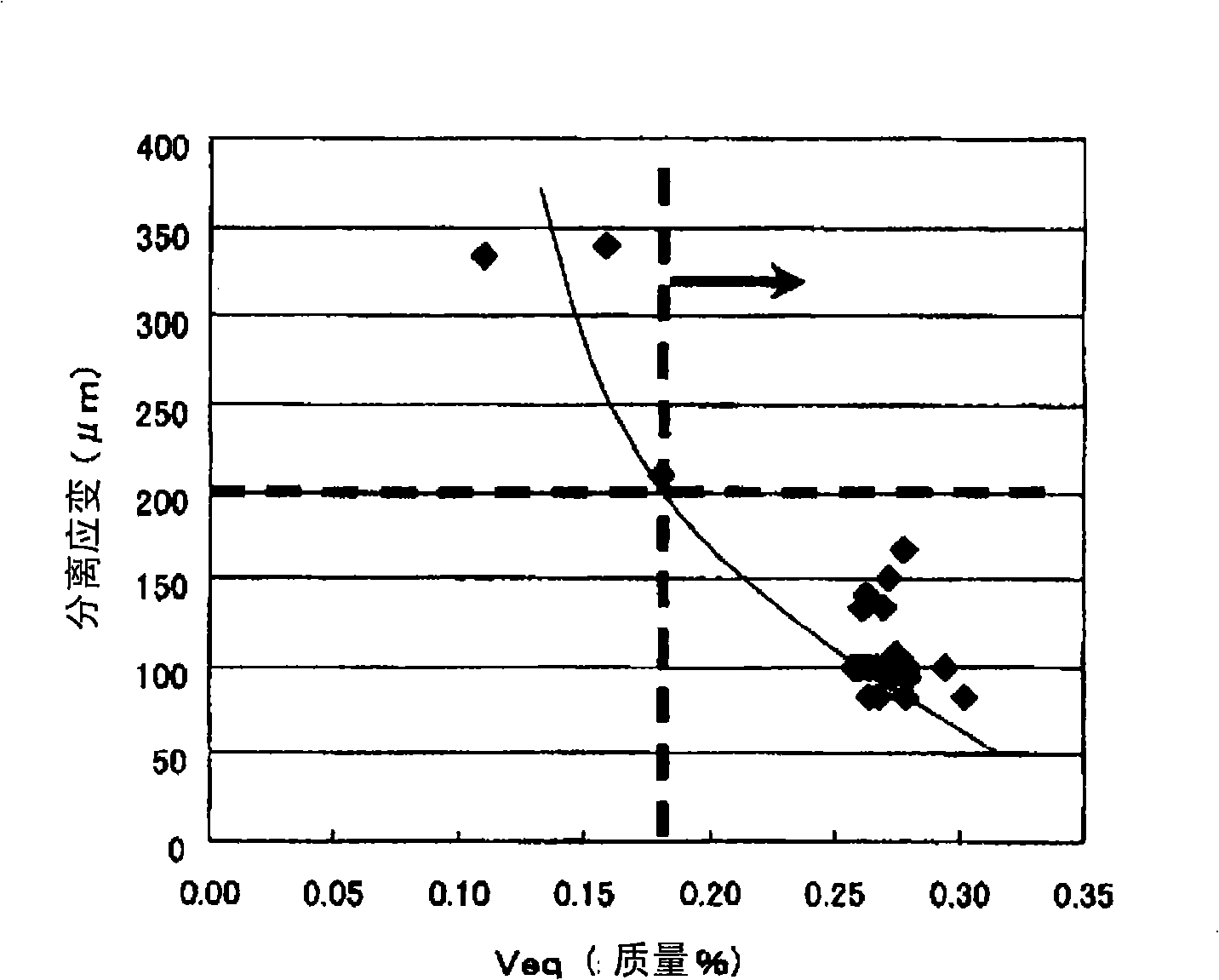

[0109] Follow the usual smelting method to melt and cast steel with the chemical composition shown in Tables 1 and 2, then billet and roll to obtain bar steel. Second, it is forged to a thickness of 25mm by hot forging. In addition, in the above-mentioned production method, the adjustment of Pc is performed by adjusting the composition and the average cooling rate at 800 to 600° C. after hot forging. In addition, the average aspect ratio of the sulfide-based inclusions is controlled by changing the temperature of the steel material before rolling, and adding Ca, Zr, Te, etc. to spheroidize the sulfide-based inclusions. These elements are all added after Al is added.

[0110] Using the obtained steel bar, the measurement of the ferrite fraction, the measurement of the average aspect ratio of the sulfide-based inclusions, and the evaluation of the fracture separation property were carried out in the following manner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com